Special efficient treatment equipment for ship door production waste

A technology for producing waste and processing equipment, which is applied in grain processing, etc., can solve problems such as difficult waste processing and low manual processing efficiency, and achieve the effect of improving processing speed and efficiency, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

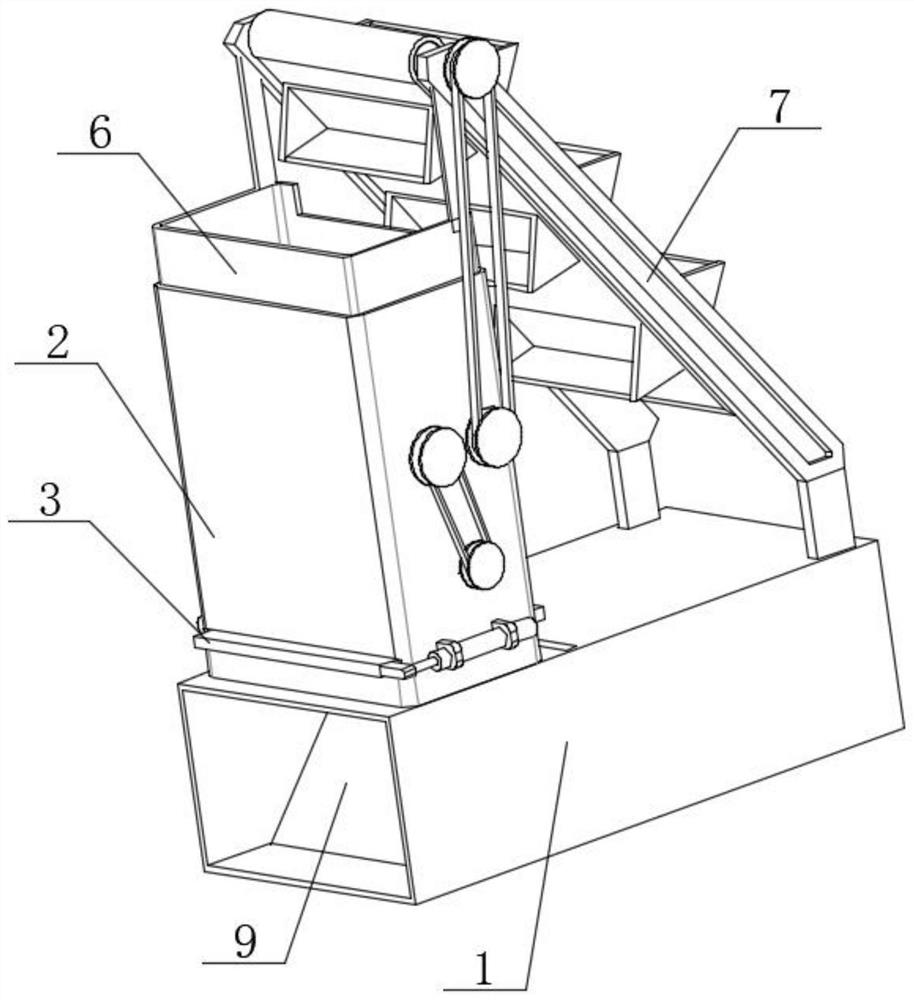

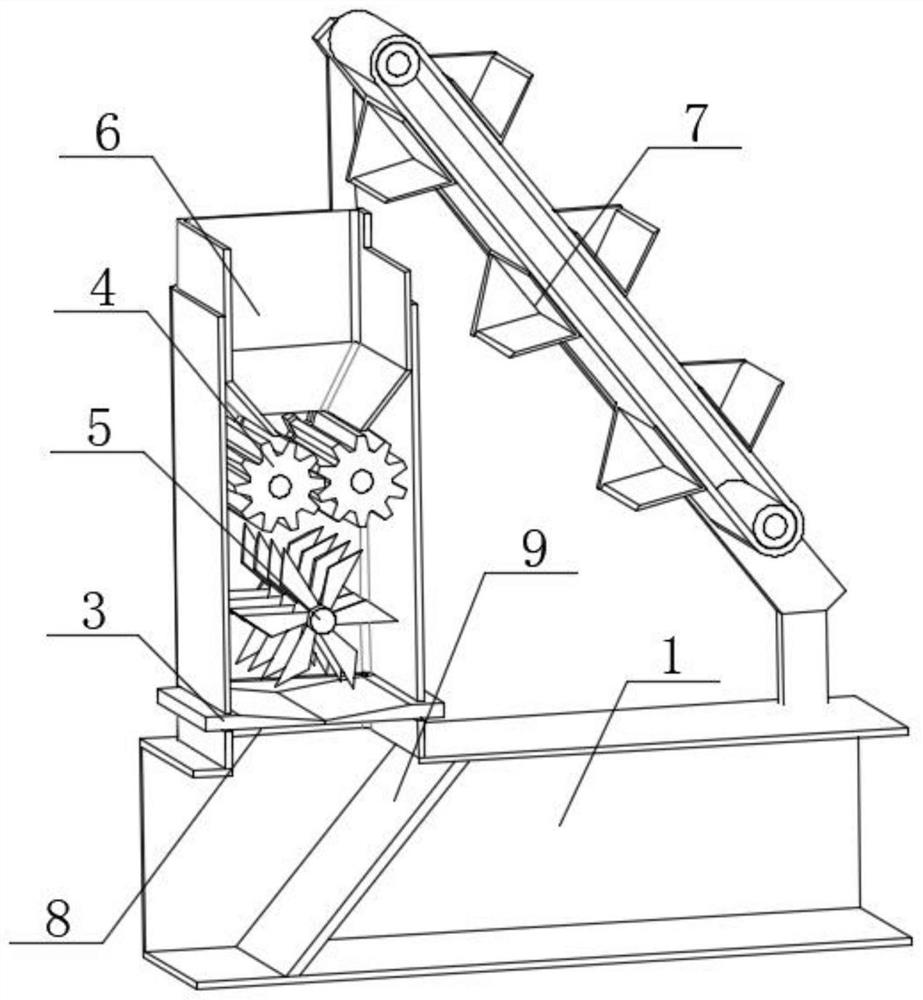

[0033] combine Figure 1-7 As shown, the invention provides a special high-efficiency treatment equipment for ship door production waste, including: a fixed box 1, a treatment box 2 is arranged on the top of the fixed box 1, and a sealing mechanism 3 is arranged inside the treatment box 2 , the inside of the processing box 2 is provided with a crushing mechanism 4 and a crushing mechanism 5, the crushing mechanism 4 is connected with the crushing mechanism 5, the crushing mechanism 5 is located under the crushing mechanism 4, and the crushing mechanism 5 is located at the sealing mechanism 3 above, the crushing mechanism 4 is used to crush the waste, the sealing mechanism 3 is used to block the waste, the shredding mechanism 5 is used to cut the waste, and the top of the processing box 2 is connected with a conical feed hopper 6, The bottom of the conical feed hopper 6 extends to the inside of the processing box 2, the conical feed hopper 6 is located above the crushing mechan...

Embodiment 2

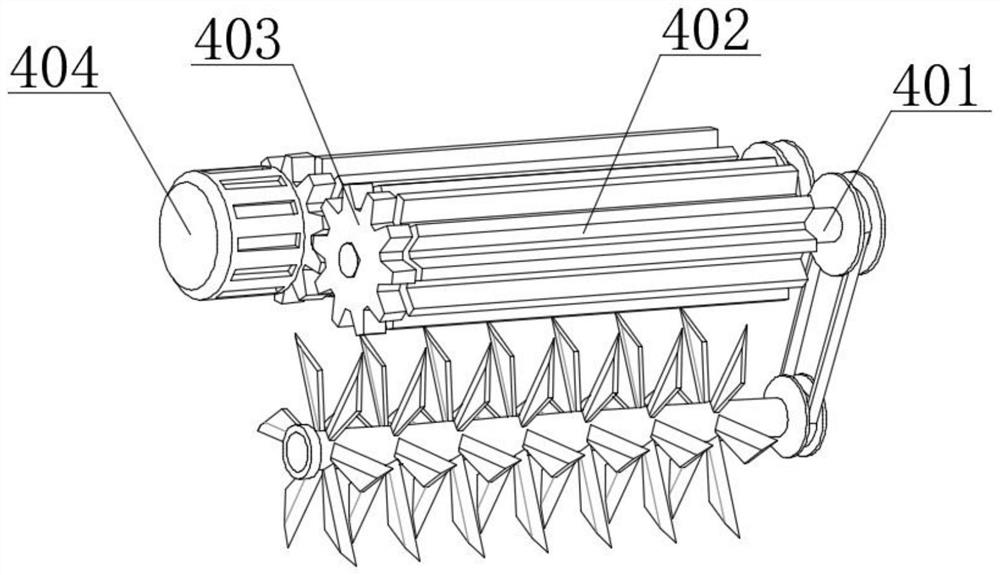

[0036] combine Figure 2-4As shown, on the basis of Embodiment 1, the crushing mechanism 4 includes two first rotating rods 401 and two crushing long rollers 402, and the two first rotating rods 401 are rotatably connected to the inside of the processing box 2, One ends of the two first rotating rods 401 all extend out of the treatment box 2, and the two long crushing rollers 402 are sleeved on the circumferential surfaces of the two first rotating rods 401 respectively, and the outer surfaces of the two long crushing rollers 402 The surfaces mesh with each other, and the two crushing long rollers 402 are located inside the processing box 2. The crushing mechanism 4 also includes two gears 403 and a driving motor 404, and the two gears 403 are respectively sleeved in the two first rotating The circumferential surface of the rod 401 and the outer surfaces of the two gears 403 are engaged with each other. The driving motor 404 is arranged on the rear end face of the processing b...

Embodiment 3

[0039] to combine Figure 5 As shown, in the above embodiment, the sealing mechanism 3 includes two installation bars 301, two sealing plates 302 and two oblique material retaining grooves 303, and the two installation bars 301 are connected to the inner wall of the processing box 2 respectively. On the front end face and the rear end face, the adjacent sides of the two installation bars 301 are provided with chute, and the two sealing plates 302 are slidingly connected between the inner walls of the two chute respectively, and the adjacent sides of the two sealing plates 302 are connected to each other. contact, the opposite sides of the two sealing plates 302 extend out of the processing box 2, and the two oblique material retaining grooves 303 are set on the tops of the two sealing plates 302 respectively, and the sealing mechanism 3 also includes two electric push rods 304, four fixed mounts 305 and two connecting fixed blocks 306, the four fixed mounts 305 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com