Device and method of high-precision five-axis linkage machining center and storage medium

A five-axis linkage, high-precision technology, used in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve problems such as reducing processing accuracy, and achieve the effect of ensuring processing quality and improving processing range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

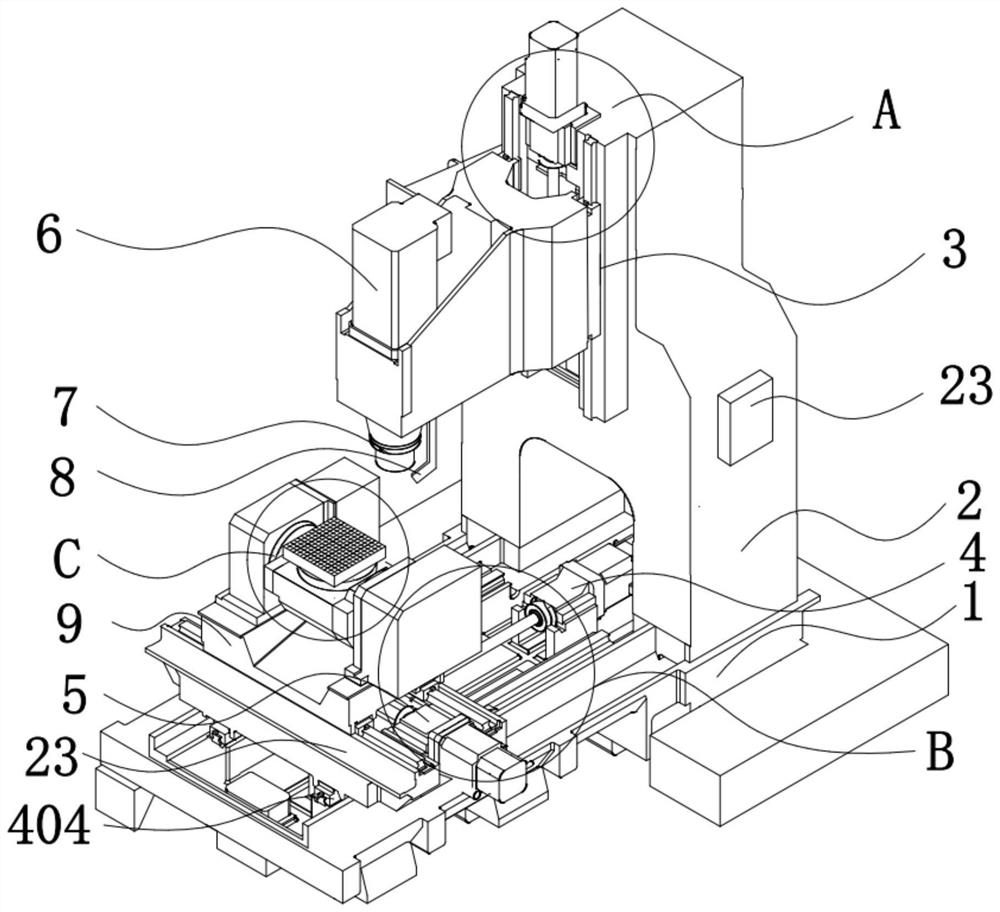

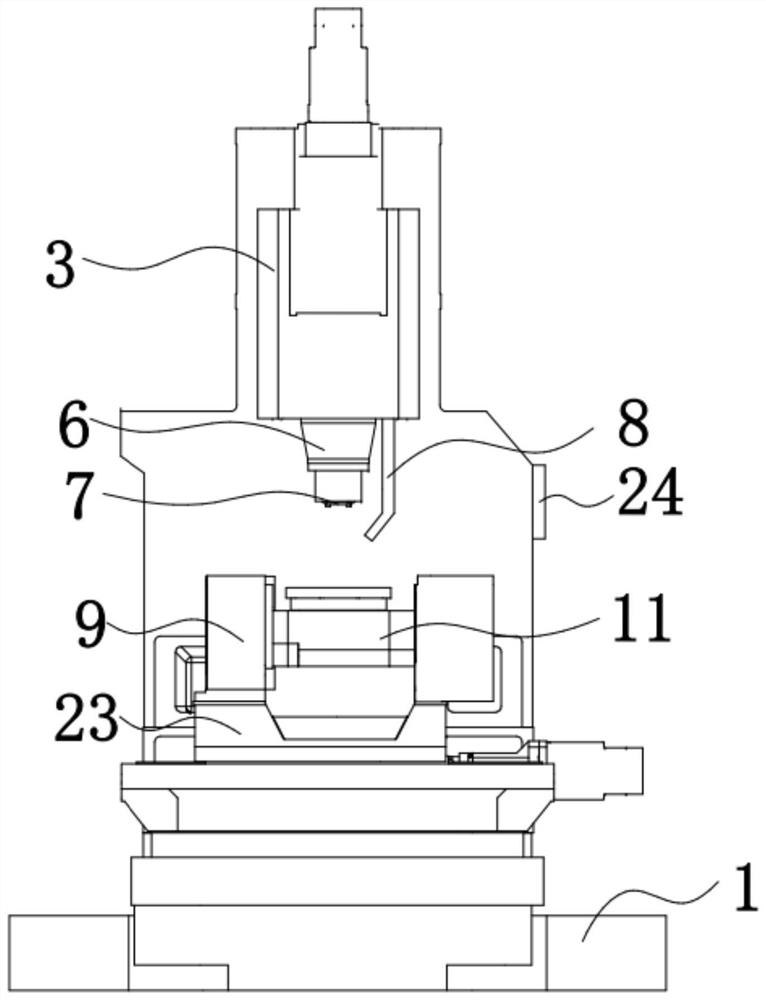

[0043] like Figure 1-6 As shown, a device of a high-precision five-axis linkage machining center includes a base 1, a bracket 2 is provided on the top of the base 1, and a controller 24 is provided on one side of the bracket 2. The controller 24 electrically controls each electrical component, and the bracket One side of the 2 is provided with a Z-axis drive device 3, the output end of the Z-axis drive device 3 is provided with a servo spindle 6, and the output end of the servo spindle 6 is provided with a tool 7, and the Z-axis drive device 3 is used to drive the servo spindle 6 to realize the Moving in the direction of the Z axis, the servo spindle 6 can drive the tool 7 to rotate, so as to perform required processing on the workpiece.

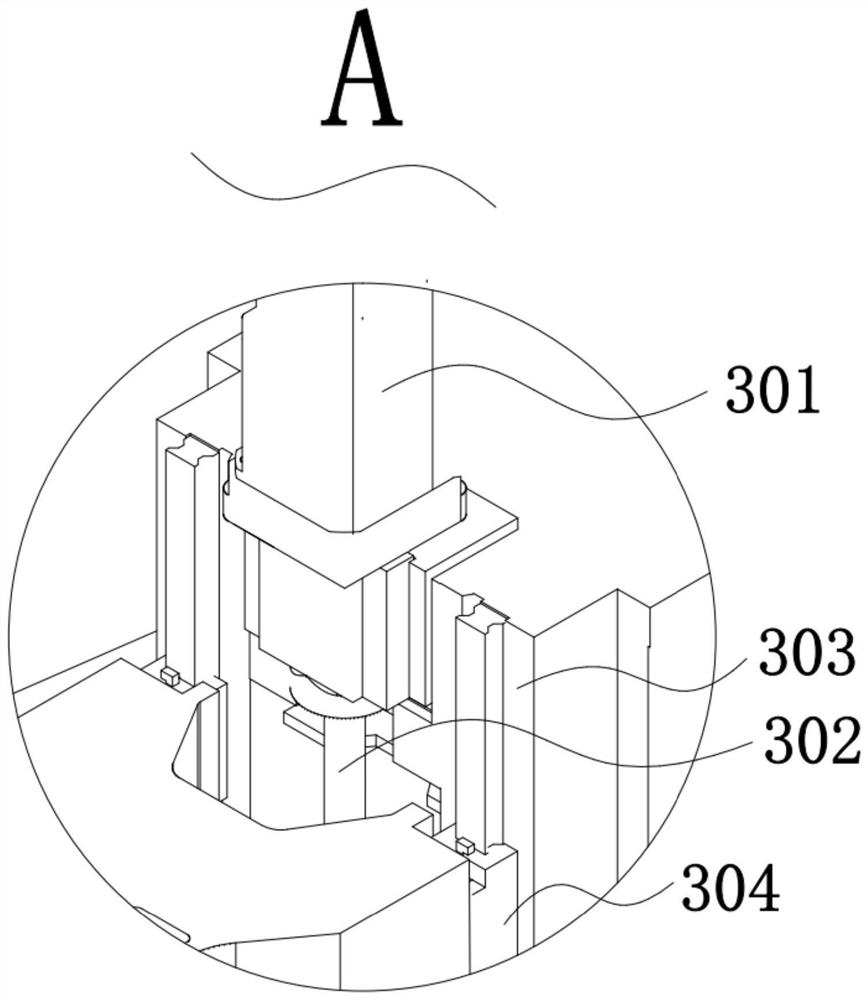

[0044] The Z-axis drive device 3 includes a first drive motor 301, one side of the first drive motor 301 is fixedly connected to one side of the bracket 2, the output end of the first drive motor 301 is provided with a first screw rod 302, ...

no. 2 example

[0054] like Figure 7 and Figure 8 As shown, based on the device of a high-precision five-axis linkage machining center provided by the first embodiment, in actual use, it is still necessary to use an additional device to position and clamp the workpiece on the top of the fixed table 13, and the positioning accuracy is low. The clamping effect is poor and cannot meet the actual needs. In order to solve this problem and improve the positioning accuracy and clamping effect of the device, the device of the high-precision five-axis linkage machining center also includes: the fixed table 13 includes multiple sets of air pumps 14, and the air pumps 14 are uniform The array is arranged on the top of the second rotating motor 12, and the main function of the air pump 14 is to pump and exhaust air, thereby realizing the clamping of the workpiece on the top of the fixed table 13. This setting method can well realize the adaptability to the workpiece, that is, regardless of the size of...

no. 3 example

[0068] like Figure 9 and Figure 10 , based on the device of a high-precision five-axis linkage machining center provided by the second embodiment, the bottom surface of the workpiece needs to be clamped by suction in actual use, so the bottom of the workpiece needs to be flat, but the bottom surface of the workpiece may not be smooth during actual processing. It belongs to the complete horizontal state, and because the bottom surface of the workpiece is not level during actual processing, when the first rotating motor 10 starts to drive the rotating table 11 to rotate around the X axis, it will drive the workpiece on the top of the fixed table 13 to tilt, and what is more will cause The workpiece is detached, thereby causing damage to the workpiece. In order to solve this problem, combined with the above process, the device of the high-precision five-axis linkage machining center also has the following process during processing:

[0069] During use, when the bottom surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com