Goods hold structure of ultra-large crude oil ship without swash bulkhead

A super-large, crude oil technology, applied in the direction of hull compartment, hull, ship construction, etc., can solve the problems of increased hull structure weight, increased assembly workload of shipyards, etc., to reduce the effect, save assembly workload, and reduce the number of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

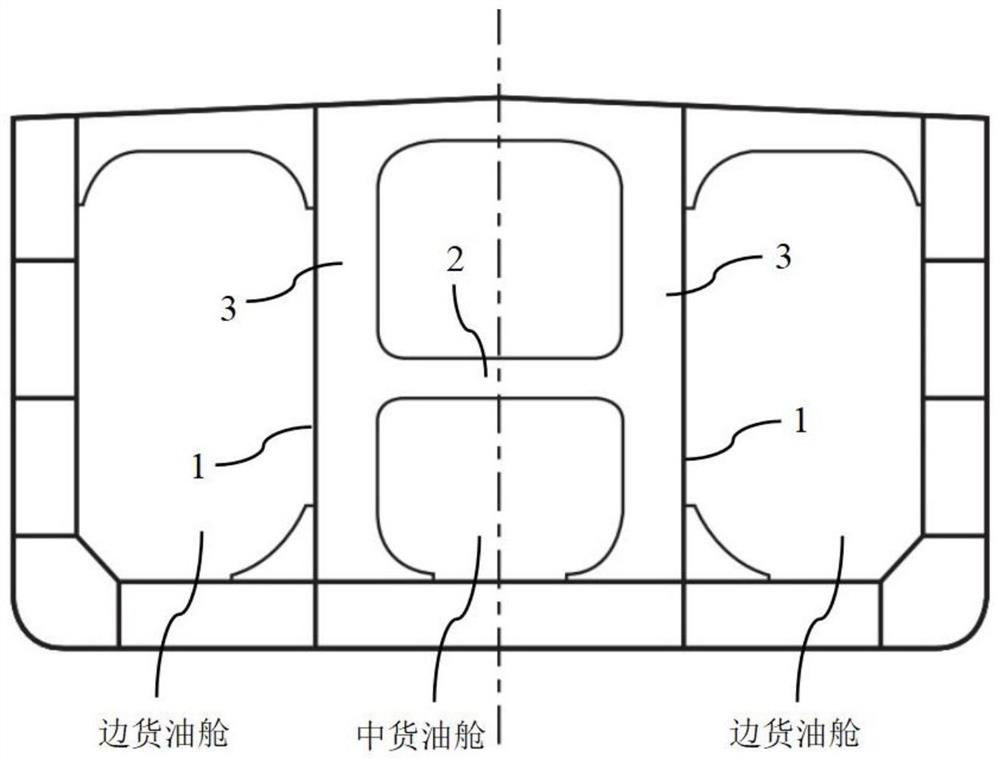

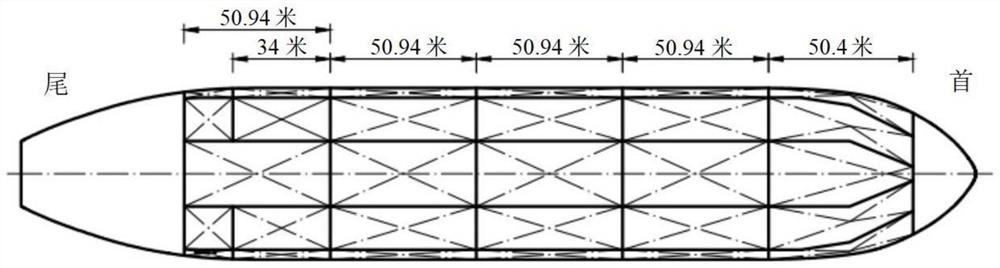

[0036] Taking a 310,000-dwt VLCC with an overall length of about 333m, a molded width of 60m, and a molded depth of 30m as an example, a set of optimal design parameters for the cargo tank structure arrangement of a VLCC without swash bulkheads is introduced.

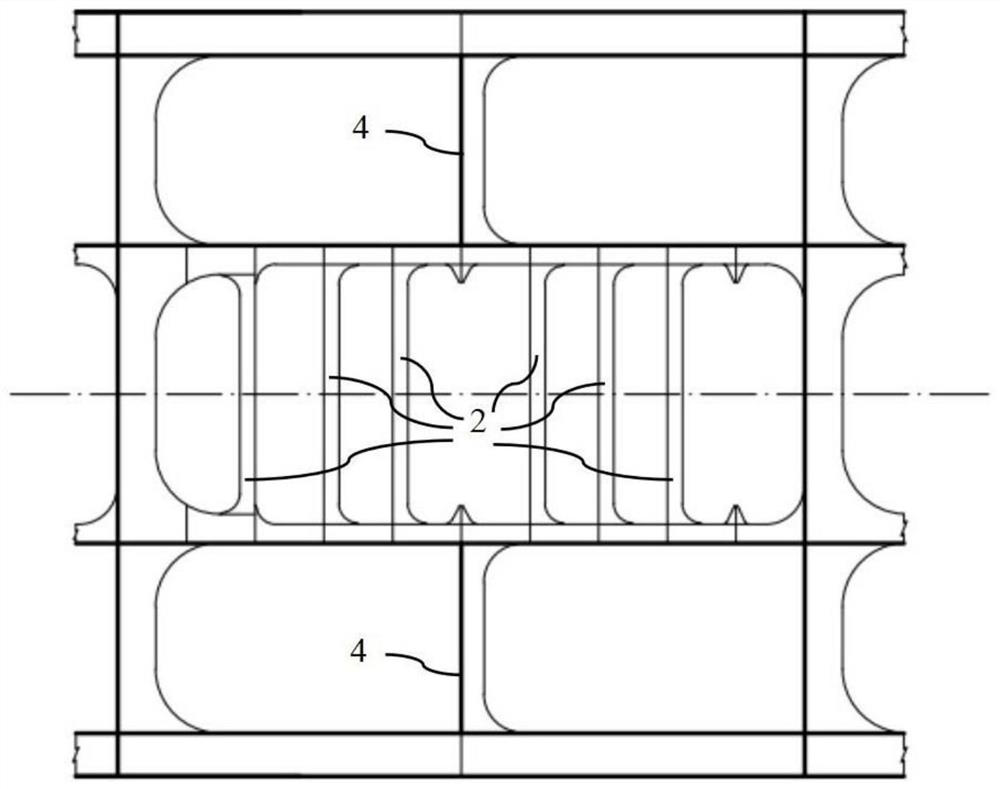

[0037] 1. Subdivision of VLCC cargo tanks without swash bulkheads. like figure 2 As shown, the cargo tank of a traditional VLCC is divided into five tanks along the longitudinal direction, and the typical tank length is 50.94m. The effective sloshing lengths of the first four side cargo oil tanks from bow to stern are all greater than 0.13 times the structural ship length, and sloshing bulkheads are required. And as Figure 5 As shown, in the subdivision form adopted by the present invention, the lengths of the cargo tanks are different, and the length of the three groups of cargo oil tanks on the shorter side is taken as 43.2m, so that the effective sloshing length is less than 0.13 times the length of the structura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com