Zanthoxylum bungeanum extraction tank

A technique for leaching and prickly ash, which is applied in the field of prickly ash leaching tanks, can solve the problems of many impurities in prickly ash oil, small contact area between leaching agent and prickly ash, and insufficient leaching of prickly ash oil, so as to increase the amount of leaching and improve the extraction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

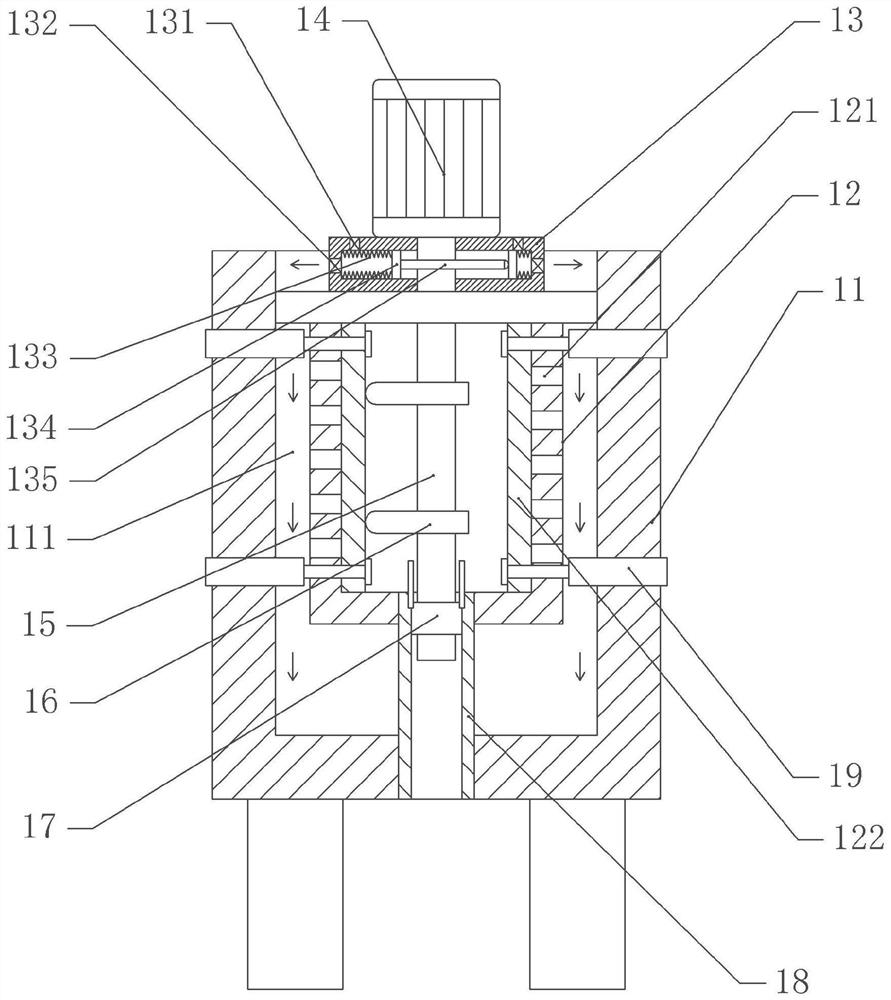

[0039] A kind of Chinese prickly ash leaching pond, as attached figure 1 And attached figure 2 Shown, comprise extracting tank 11 and be fixed in the squeezing vat 12 in extracting tank 11, form cavity 111 between squeezing tank 12 and extracting tank 11, first driving member 14 ( The first drive member 14 is a motor), the output shaft of the first drive member 14 is coaxially fixed with the squeeze shaft 15 located in the squeeze barrel 12, and the squeeze shaft 15 is fixed with several first cams 16 by bolts, and the adjacent first The cams 16 are arranged in a staggered manner.

[0040] An air box 13 is arranged between the first driving member 14 and the leaching tank 11, and the pressing shaft 15 penetrates through the air box 13 and is fixedly connected with the output shaft of the first driving member 14. Both sides of the air box 13 are provided with air chambers, An air plate 134 is horizontally slidably connected in the chamber, and an elastic member is arranged b...

Embodiment 2

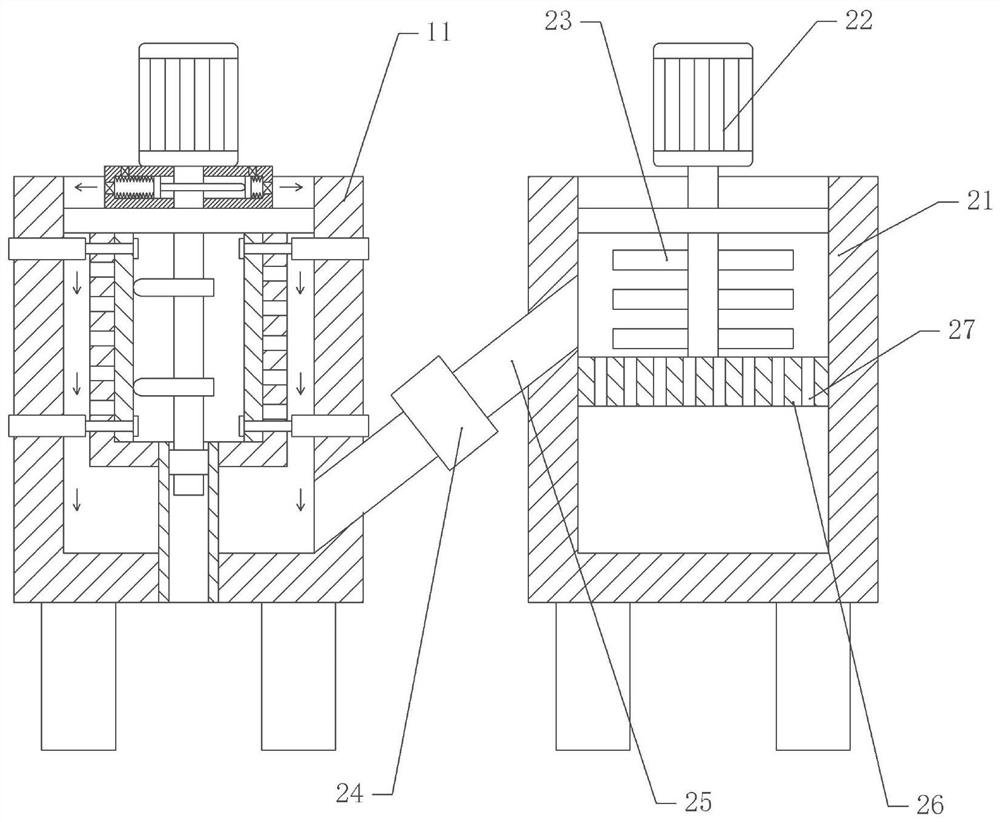

[0049] The difference between embodiment two and embodiment one is that, as attached image 3 And attached Figure 4 As shown, it also includes a filter tank 21, the filter tank 21 is bolted with a second driver 22 (the second driver 22 is a motor), the second driver 22 is electrically connected to the controller, and the output shaft of the second driver 22 A number of stirring blades 23 are fixed on it, and a filter plate 26 located below the second driving member 22 is fixed by bolts in the filter tank 21 , and a filter hole 27 is opened on the filter plate 26 .

[0050] A pump assembly and a pipeline 25 are arranged between the leach pool 11 and the filter pool 21, the pump assembly is a centrifugal pump 24, and the leach pool 11 and the filter pool 21 are communicated with the leach pool 11 and the filter pool 21 by the centrifugal pump 24 and the pipeline 25 The connection between the pipeline 25 and the filter tank 21 is located above the filter plate 26 , and the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com