Novel process for dyeing cotton chinlon ammonia imitated denim

A new technology, nylon technology, applied in the field of textile products, can solve problems affecting product quality, etc., and achieve the effect of improving product qualification rate and comfortable wearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

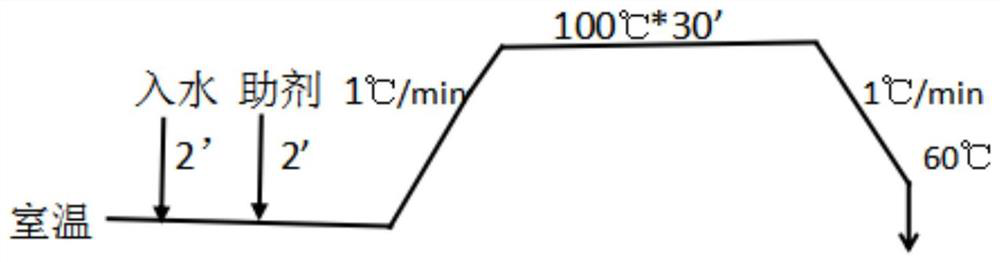

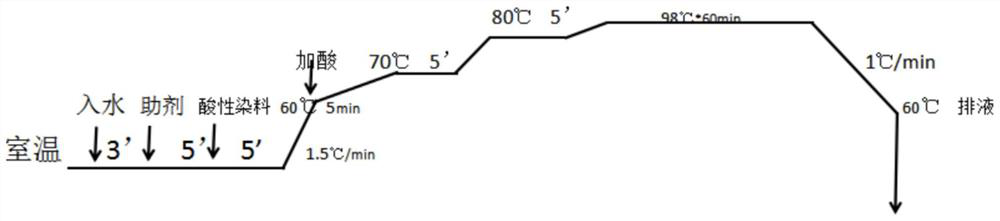

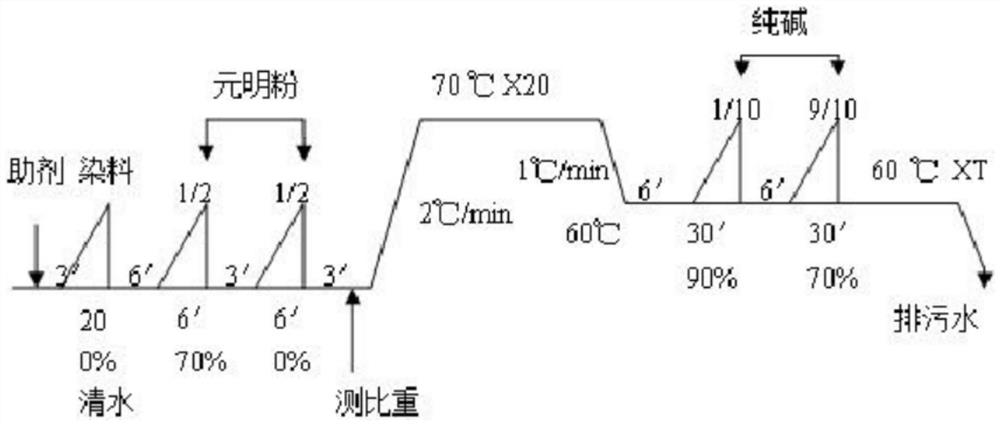

[0043] as attached figure 1 to attach image 3 Shown:

[0044] The invention provides a new cotton-nylon-spandex imitation denim dyeing process, which comprises 32S / 1 cotton, 75D / 68F nylon and 105D spandex twill imitation denim fabric woven into a single-sided weave structure, and the composition content is 41%, Composition of 36% and 21%.

[0045] Among them, the following steps are included:

[0046] Gray cloth preparation, seam turning, vat entry, pretreatment, neutralization, nylon dyeing, primary cleaning, acid color fixation, cotton dyeing, soaping, secondary cleaning, cotton color fixation and vat exit, among which the pretreatment process is in the bath join in turn;

[0047] Refining degreasing agent 1% owf;

[0048] Degreaser 1% owf;

[0049] Soda ash 5% owf;

[0050] Hydrogen peroxide 3% owf;

[0051] Oxygen bleach stabilizer 0.5% owf;

[0052] The proportion of the degreasing agent is 30%, and the bath ratio is 1:2.5. After entering the water 2' at room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com