Construction auxiliary installation device and construction method thereof

An installation device and hollow technology, which is applied to valve devices, cocks including cut-off devices, transportation and packaging, etc., can solve the problems of inability to install glass curtain walls and inconvenient operation of glass curtain walls, so as to improve convenience, practicability, and security. The effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

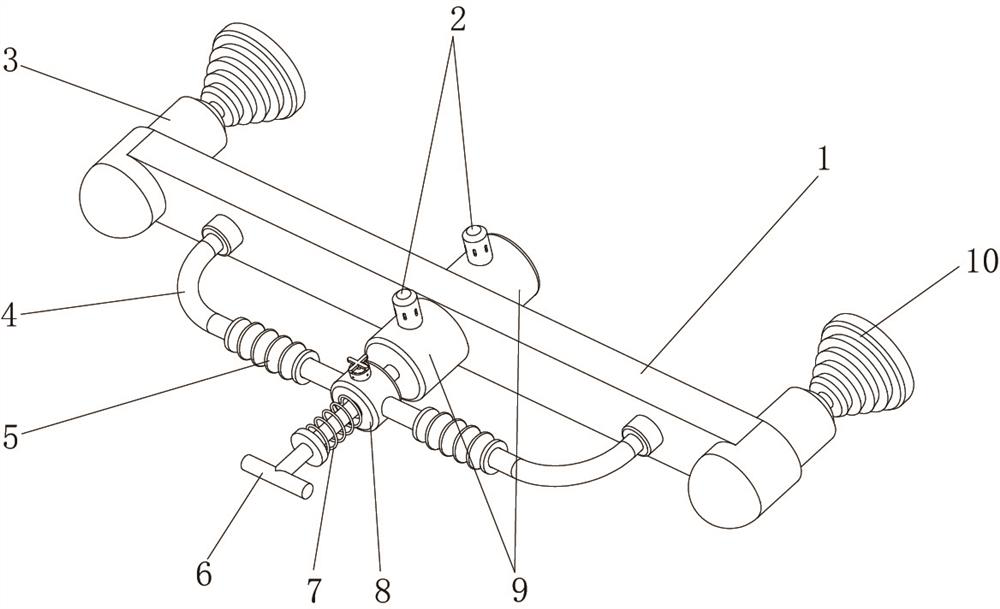

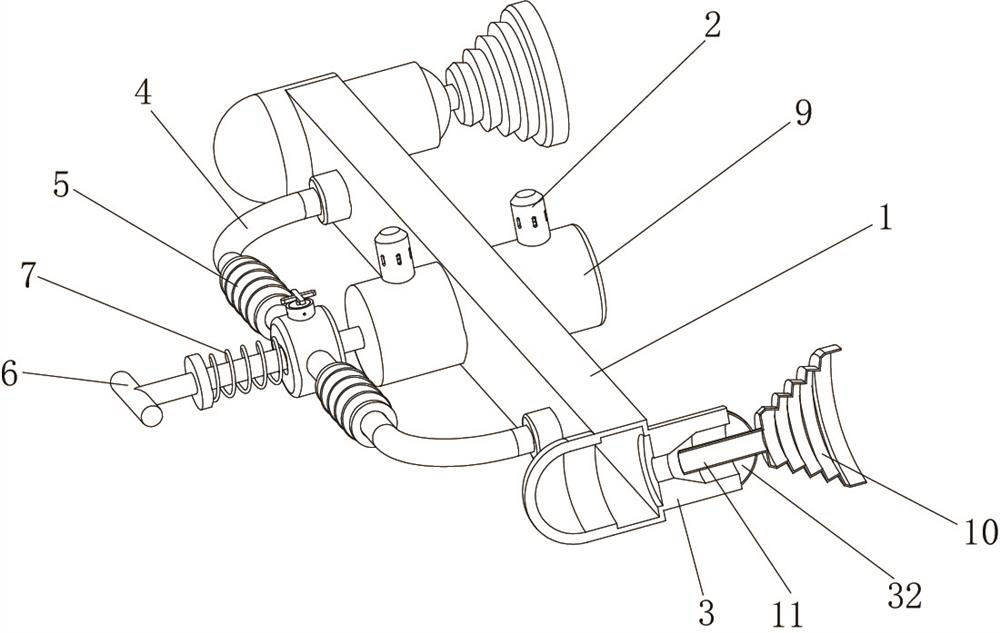

[0070] A construction auxiliary installation device, such as Figure 1-8 shown, including:

[0071] Hollow frame 1;

[0072] The connecting seat 3, the connecting seat 3 is fixed on both sides of the hollow frame 1, and the connecting seat 3 is connected with the inside of the hollow frame 1;

[0073] A suction cup 10, one end of the suction cup 10 is fixed with a connecting pipe 11, the connecting pipe 11 is installed in the connecting seat 3, and the sucking cup 10 is connected to the connecting seat 3 through the connecting pipe 11;

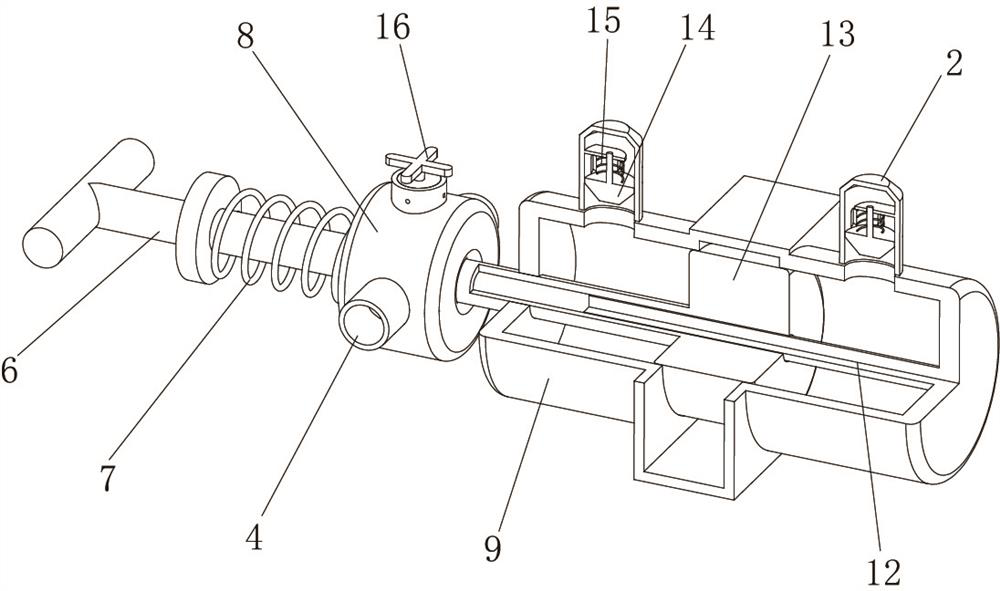

[0074] The exhaust chamber 9 is integrally arranged on both sides of the middle part of the hollow frame 1, and the exhaust chamber 9 is provided with an exhaust valve;

[0075] Piston 13, the piston 13 is adapted to the exhaust chamber 9, and the piston 13 is slidably connected in the exhaust chamber 9;

[0076] A guide rod 12, one end of the guide rod 12 is fixed on one side inner wall of an exhaust chamber 9, and the piston 13 is slidabl...

Embodiment 2

[0098] A construction auxiliary installation device, such as Figure 1-8 As shown, in order to facilitate construction; this embodiment makes the following improvements on the basis of embodiment 1: the specific structure of the glass curtain wall includes:

[0099] The curtain wall frame body 23 is used as the main frame of the glass curtain wall unit for building installation;

[0100] A glass curtain wall unit, the glass curtain wall unit includes a curtain wall glass 24 and an installation frame 26, and the curtain wall glass 24 is fixed inside the installation frame 26;

[0101] The locking part is used to fix the glass curtain wall unit on the curtain wall frame body 23;

[0102] Decorative baffle 25 , the decorative baffle 25 is clamped on the side of the locking part away from the curtain wall frame body 23 , and plays the role of decoration and protection.

[0103] In order to ensure the locking effect; Figure 6-8 As shown, the locking part includes:

[0104] The...

Embodiment 3

[0110] A construction method for a construction auxiliary installation device, comprising the following steps:

[0111] S1: Construction workers transport the glass curtain wall unit to the designated location;

[0112] S2: Press the suction cup 10 against the surface of the curtain wall glass 24 of the glass curtain wall unit;

[0113] S3: Pull the operating rod 6 repeatedly to discharge the gas in the hollow frame 1 and the suction cup 10 from the exhaust valve to realize the adsorption of the curtain wall glass 24;

[0114] S4: holding the anti-slip sleeve 5, clamping the glass curtain wall unit to the curtain wall frame body 23;

[0115] S5: Turn the knob 16 to allow outside air to enter the hollow frame 1, and release the adsorption effect of the suction cup 10 on the glass curtain wall unit;

[0116] S6: Install adjacent glass curtain wall units according to the above method;

[0117] S7: Rotate the clamping plate 27 so that both ends of the clamping plate 27 are tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com