Method for filling open pit

A filling method and open pit technology, applied in the mining field, can solve the problems of the deterioration of the stability of the pile body, the consumption of cementitious agent, and the failure of the strength of the pile body, so as to shorten the water drainage and maintenance period, increase the utilization rate of tailings, and reduce the cementation. effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

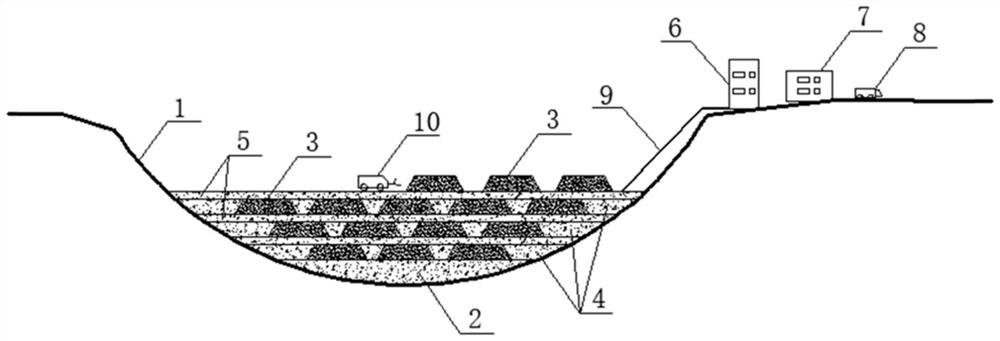

[0041] The applicant tried the filling method of the present invention in the filling of the open pit of a certain mine in the south (production scale of 500,000 t / a, located at the edge of the city). A large open pit about 400m long, 200m wide, and 70m deep. Due to the need for continuous replacement of resource mining, the open pit was closed and transferred to the underground to continue production. The underground mining method is mainly segmented empty and then filled. The up...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com