Electric power iron tower angle steel delivery detection equipment

A factory inspection and power tower technology, which is applied in the direction of measuring devices, testing material hardness, and material analysis through optical means, can solve problems such as accidents, reduce the difficulty of loading and unloading, improve detection efficiency, and achieve reasonable structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

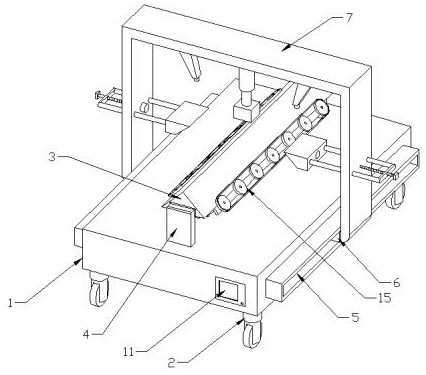

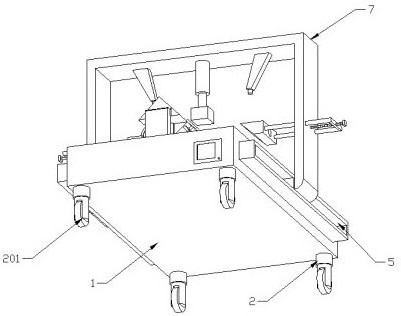

[0028] see Figure 1-6 As shown, the present embodiment is a factory inspection equipment for the angle steel of a power tower, including a workbench 1, the four corners of the bottom of the workbench 1 are connected with columns 2, and the top of the workbench 1 is provided with a storage platform 3, and the end of the storage platform 3 is connected to the A support base 4 is connected between the workbench 1, and guide rails 5 are connected to the left and right side walls of the workbench 1, and a linear motor 6 is installed on the guide rail 5, and a detection frame 7 is connected between the outer walls of the two linear motors 6, The bottom of the horizontal end of the detection frame 7 is connected with a hydraulic rod 8, the movable end of the bottom of the hydraulic rod 8 is connected with a hardness tester 12, the left and right sides of the hydraulic rod 8 are provided with oblique brackets 9, and the upper end of the oblique bracket 9 is fixedly connected with the ...

Embodiment 2

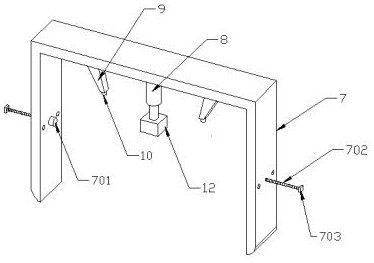

[0035] On the basis of Embodiment 1, a driving motor 701 is connected to the inner wall of the vertical part of the detection frame 7 , a screw rod 702 is connected to the power output end of the driving motor 701 , and a stopper 703 is connected to the end of the screw rod 702 . The vertical part of the detection frame 7 is movably inserted with a U-shaped rod 704, and the middle part of the U-shaped rod 704 is provided with a threaded hole 705. The threaded hole 705 is screwed to the outer wall of the screw rod 702, and one end of the U-shaped rod 704 close to the storage table 3 is connected with a correction block. 706.

[0036] One end of the rectification block 706 near the storage table 3 is provided with a profiled inclined surface, and the profiled inclined plane is parallel to the outer wall of the storage table 3, and the end of the correction block 706 away from the storage table 3 is provided with a relief opening, and the volume of the relief hole is larger than t...

Embodiment 3

[0040]On the basis of Embodiment 1, the bottom of the storage table 3 is connected with a rectangular seat 18, and the left and right ends of the rectangular seat 18 are provided with accommodating cavities 13, and the accommodating cavity 13 is connected with an electric push rod 14, and the electric push rod 14 The movable end is connected with a supporting mechanism 15 , the bottom of the rectangular seat 18 is connected with a double-headed motor 16 , and the output end of the double-headed motor 16 is connected with a first bevel gear 17 .

[0041] The supporting mechanism 15 includes a bracket 151, the outer wall of the bracket 151 is connected with a side plate 152, the front portion of the side plate 152 is rotatably connected with a driving shaft 153, and the lower end of the driving shaft 153 is connected with a second bevel gear 154, and the side plate 152 is along the A plurality of driven shafts 155 are connected for rotation in the front and rear directions, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com