Glue solution production device for preparing glass fiber reinforced plastic material and production method of glue solution production device

A production device and technology of glass fiber reinforced plastics, applied in separation methods, chemical instruments and methods, mixers with rotating stirring devices, etc., can solve problems such as the inability to guarantee the viscosity of the glue and the degree of curing of the glue, and achieve qualified quality, The effect of preventing mixing ratio errors and ensuring the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

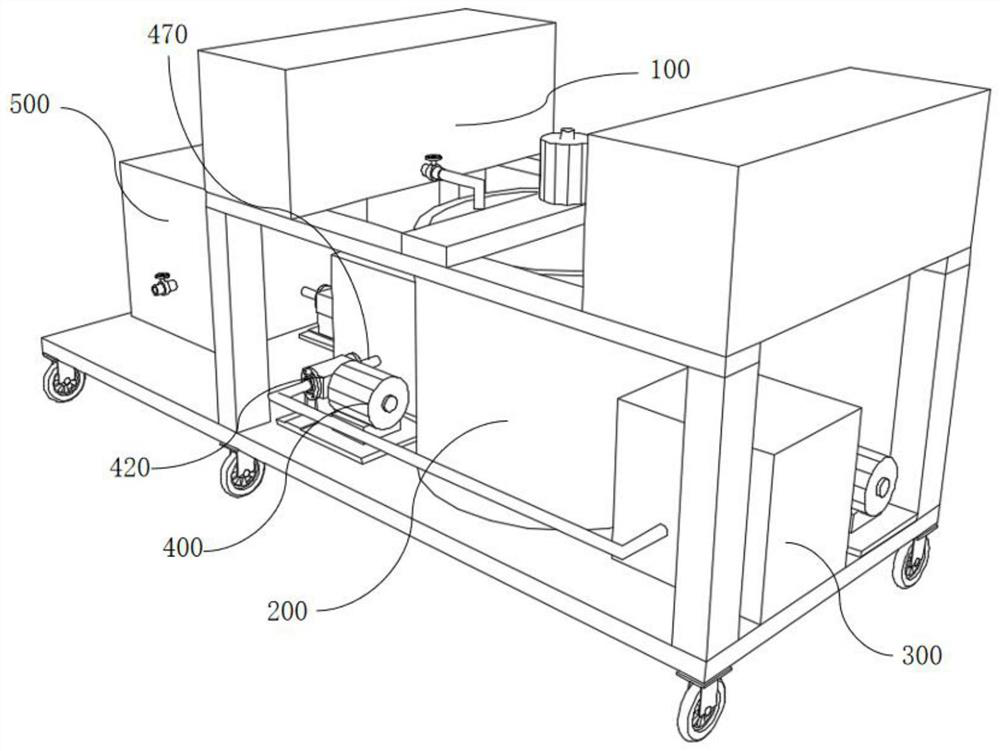

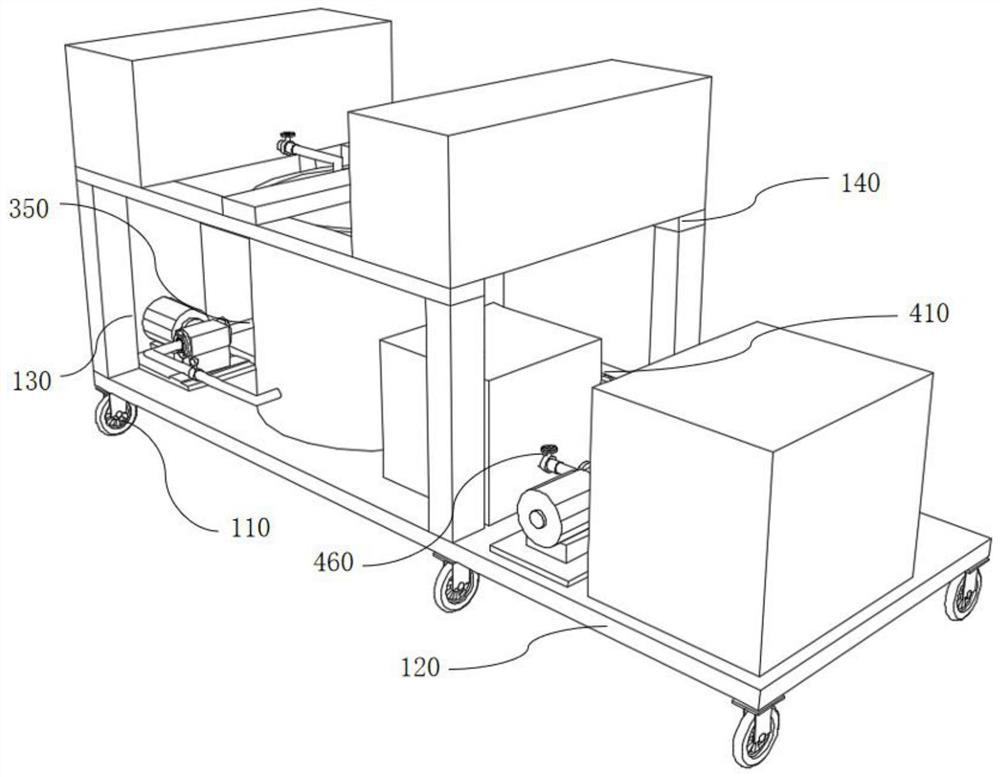

Image

Examples

Embodiment 2

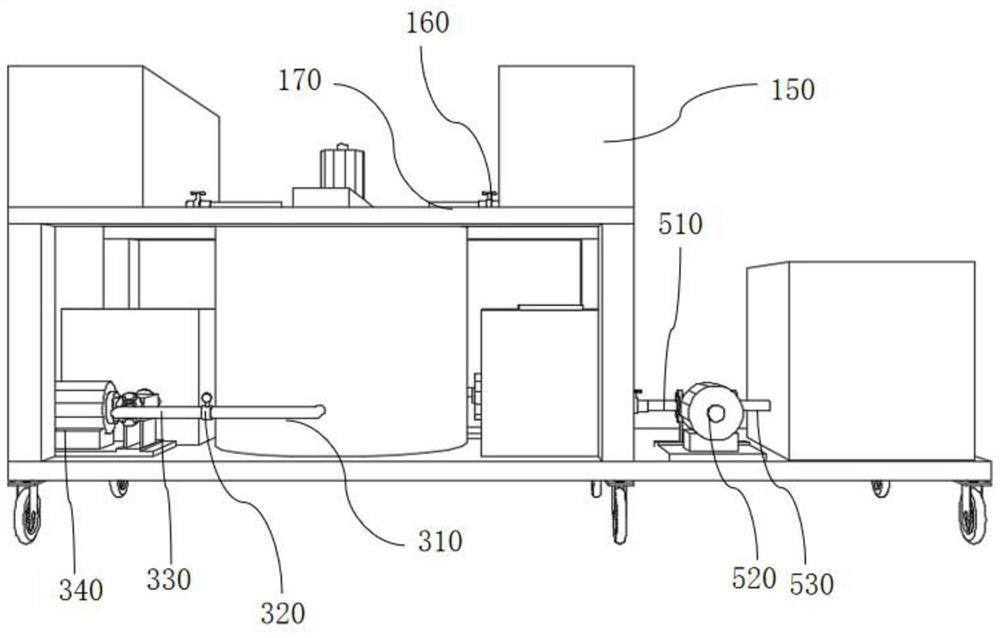

[0042] A kind of production method of the glue solution production device that is used for the preparation of FRP material, comprises the following steps:

[0043] Step 1: Put the resin into the box body 240 from the discharge pipe 270, open the water control valve 160 and the discharge valve 260, water flows into the box body 240 from the water outlet pipe 170, start the drive motor 210, and the drive motor 210 drives the impeller 230 to rotate fully The materials are stirred and mixed to obtain crude glue;

[0044] Step 2: Start the transfer pump 340, and the stirred crude glue is transported from the outlet pipe 310 to the filter box 360 through the flow meter 320 for coarse filtration, and the flow meter 320 controls the output rate of the glue to obtain the glue;

[0045] Step 3: start the transfer pump 420, the filtered glue is sent to the liquid storage tank 430 by the transfer pump 420 through the feed pipe 410, the heater 450 keeps the temperature constant at 15°C, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com