Coulter mixer

A mixer and coulter technology, applied to mixers, mixers with rotating containers, mixer accessories, etc., can solve the problems of increased manual cleaning, dead material, and difficulty in discharging materials, so as to facilitate maintenance and management and improve use Longevity and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

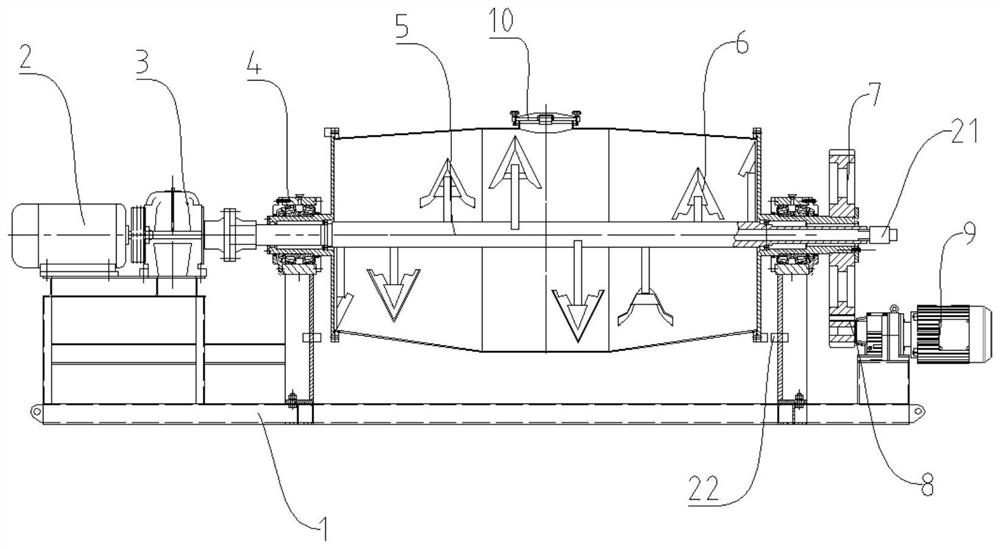

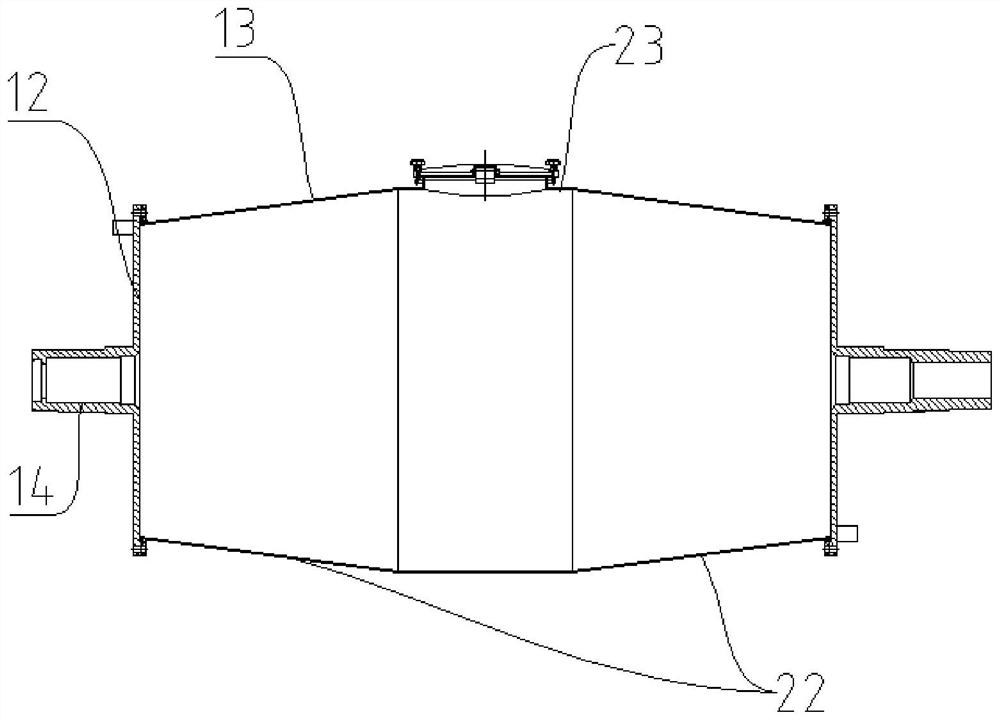

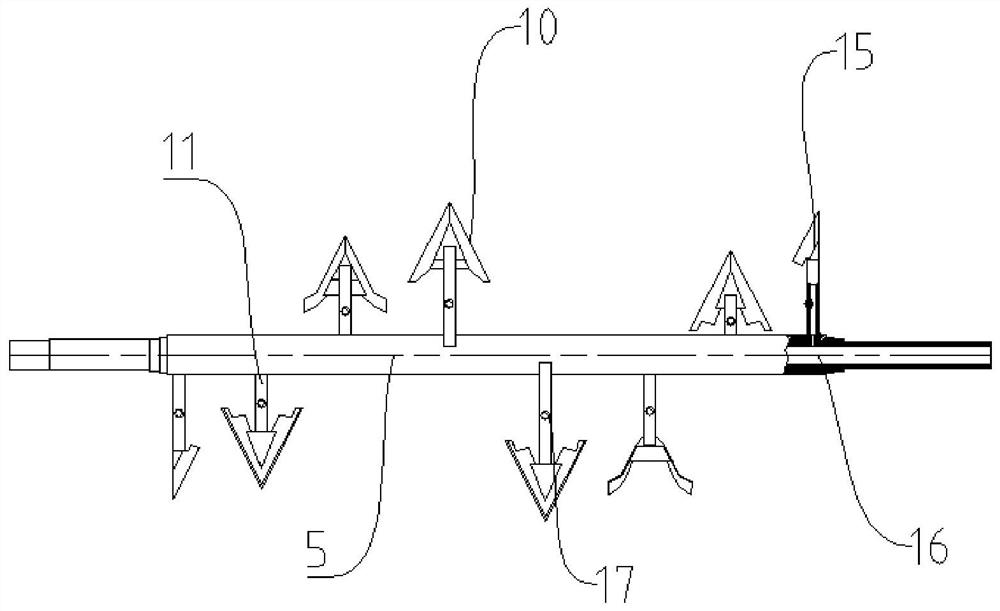

[0032] refer to Figure 1 to Figure 6 A kind of coulter mixer shown, comprises frame 1, stirring paddle motor 2, speed reducer 3, mixing tank and housing motor 9, and stirring paddle motor 2, speed reducer 3, mixing tank and housing motor 9 are fixed on On the frame 1, the stirring paddle motor 2 is connected with the speed reducer 3, the speed reducer 3 is connected with the stirring shaft 5, the stirring shaft 5 passes through the middle of the mixing barrel transversely, and the stirring shaft 5 is equipped with a stirring Paddle, stirring paddle comprises paddle 6 and paddle handle 11, and paddle 6 is fixed on the paddle handle 11, and paddle handle 11 is connected with stirring shaft 5, and described mixing bucket comprises end cover 12 and housing 13, and end cover 12 is two First, the end caps 12 are arranged at both ends of the housing 13, and the housing 13 gradually shrinks from the middle to both ends and forms a folded structure, and the middle of the housing 13 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com