Spraying robot anti-flying paint attachment system and attachment method

A technology for spraying robots and anti-flying paint, applied in the direction of spraying devices, etc., can solve the problems of affecting the spraying effect, waste of resources, and poor actual use of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

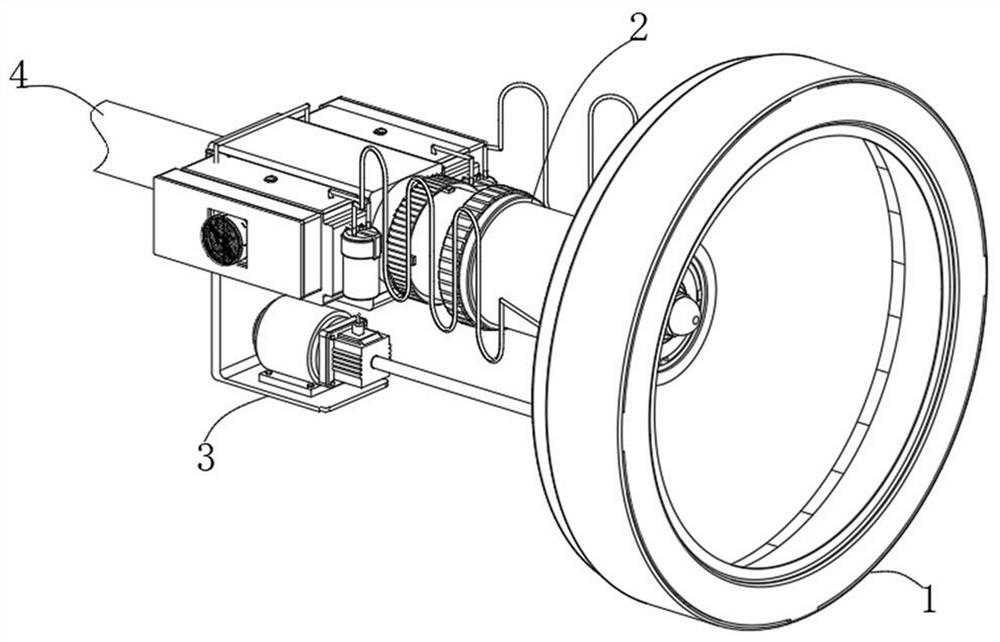

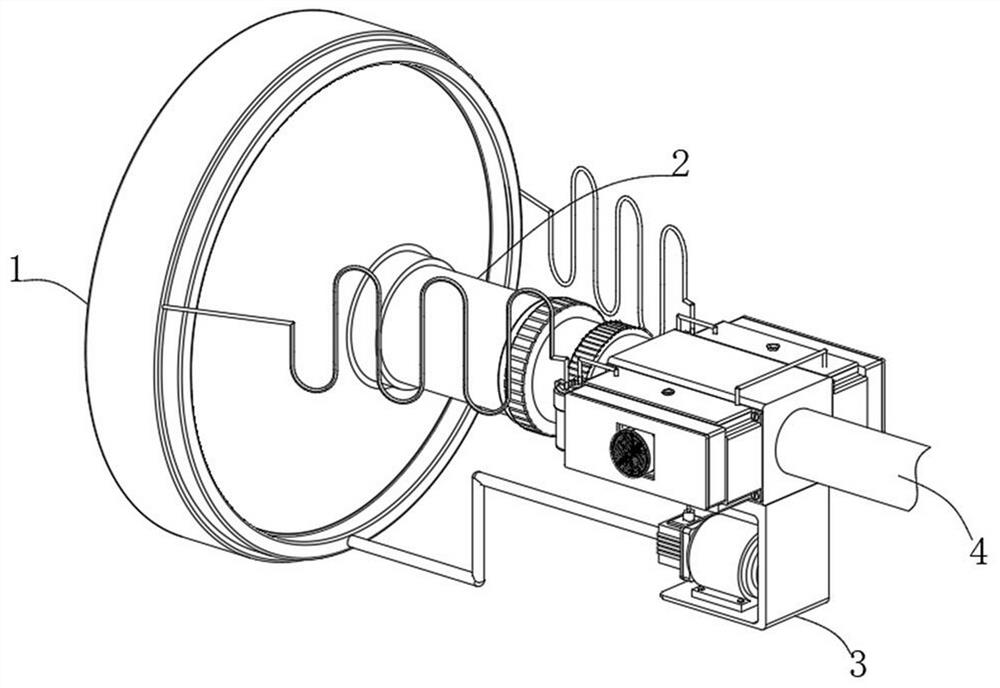

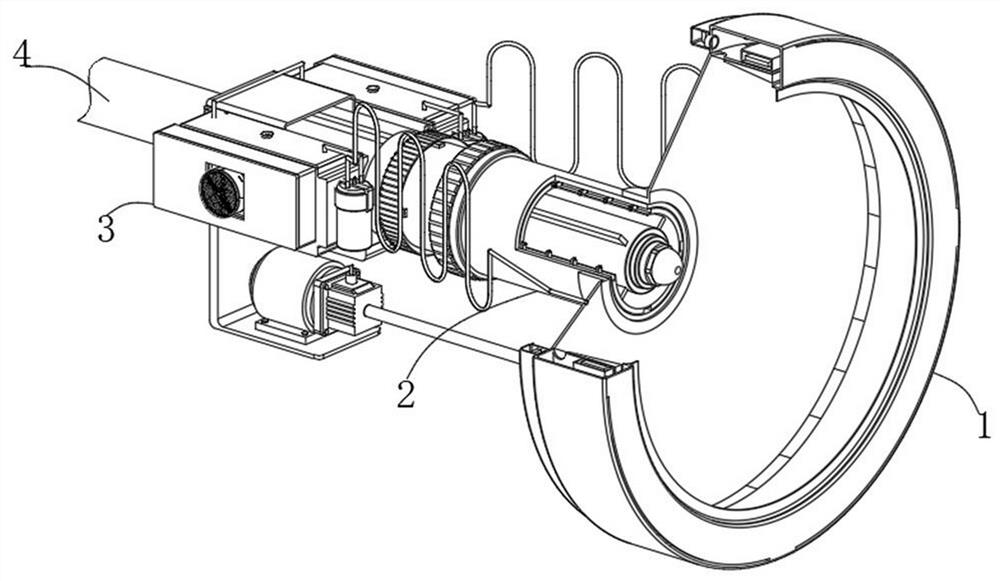

[0036] refer to Figure 1-Figure 10: An anti-flying paint attachment system for a spraying robot, comprising: a painting equipment body 4, an adjustment mechanism 2, a barrier mechanism 1 and a circulation mechanism 3, the adjustment mechanism 2 includes a bottom pipe 201, connecting parts and positioning parts, and the establishment of the bottom pipe 201 provides The installation basis for other functional parts of the equipment, and at the same time enable the equipment to be firmly installed at the designated use position. The bottom pipe 201 is slidably sleeved on the outer surface of the painting equipment body 4. The connecting parts include the connecting pipe 204. The establishment of the connecting pipe 204 is convenient for other equipment. The installation and setting of the functional parts, the connecting pipe 204 is slidingly sleeved on the outer surface of the bottom pipe 201, and the outer surface of the connecting pipe 204 is slidingly sleeved with a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com