Tool for coating sealant on outer surface of nut and coating method

A technology of sealant and outer surface, which is applied to the device and coating of the surface coating liquid, which can solve the problems of uneven sealant thickness, inconsistent weight, difficult sealant thickness, etc., to avoid uneven glue coating Uniformity, easy storage and use, and better appearance consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] For example: brushing sealant for a certain type of connecting bolt;

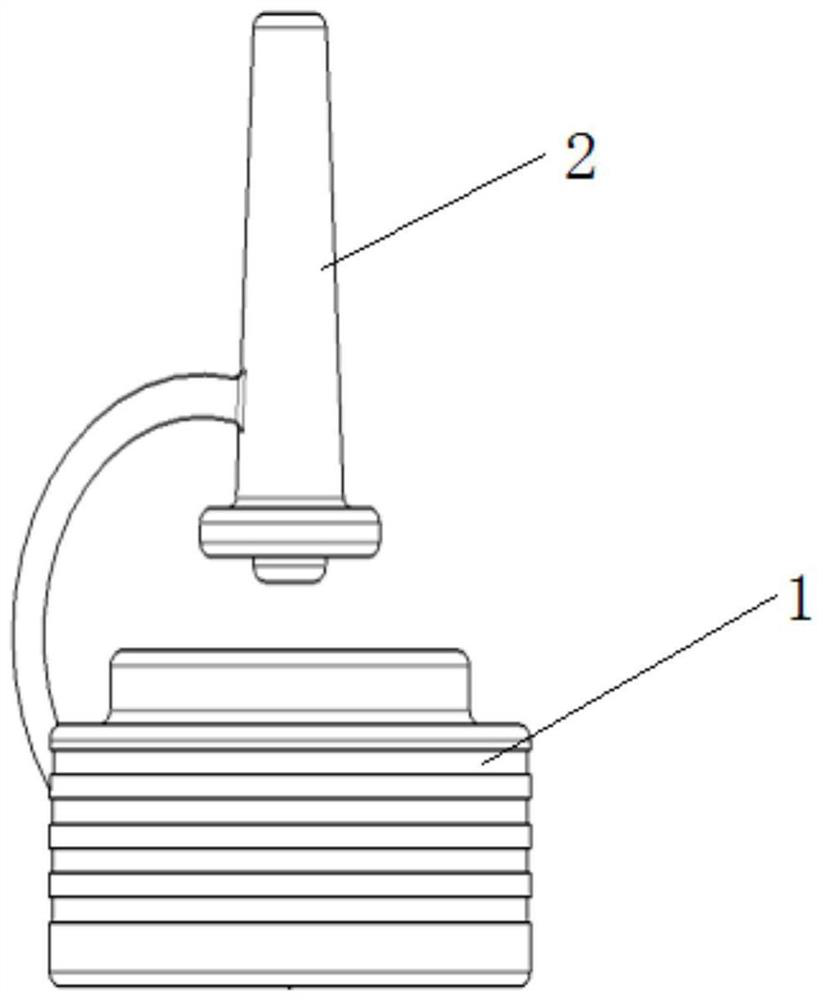

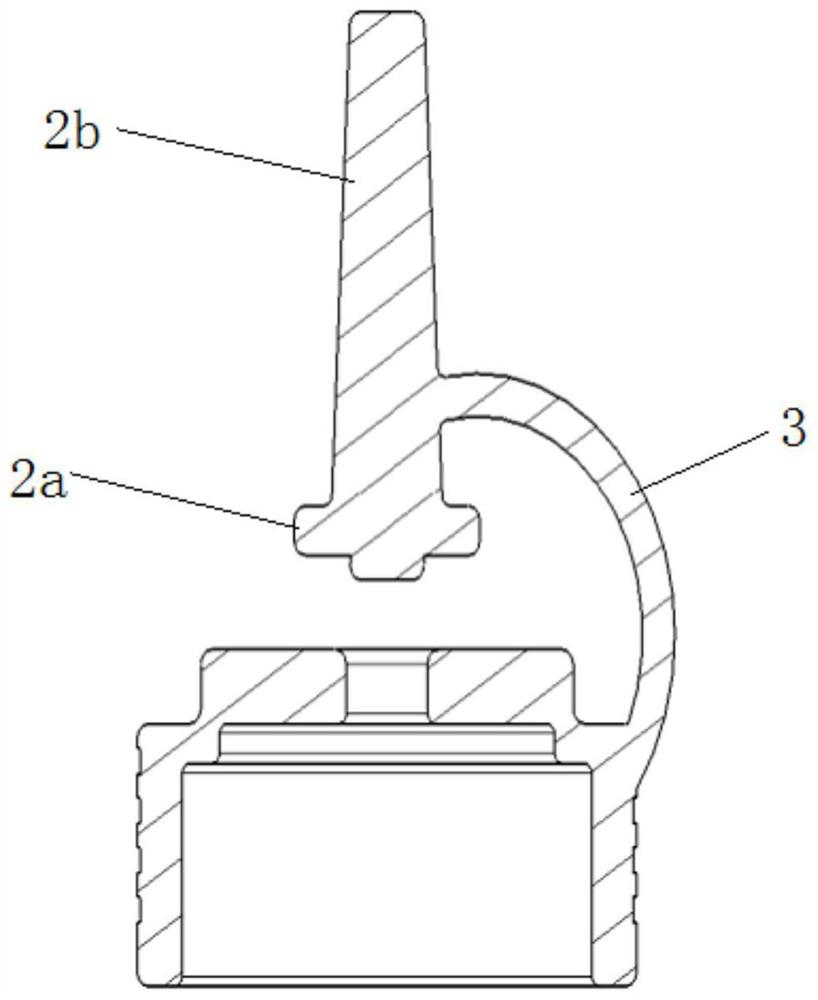

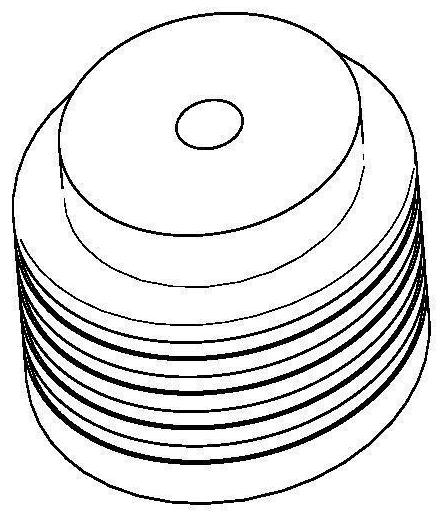

[0027] The schematic diagram of the customized tooling for the hydrophobic seal is shown in figure 1 , consisting of a sealing cover 1 and a plugging post 2; the inside of the sealing cover 1 is a cavity that can accommodate bolts, and a boss is arranged on its upper end, and a through hole is opened in the center of the boss, and the diameter of the through hole is the same as that of the plugging post 2 It is used for glue injection and positioning; one end of the plugging column 2 is a step shaft, and the front end of the step shaft is a plug 2a, and the plug 2a can pass through the through hole for compacting the sealant to ensure that the sealant The gas inside is discharged from the through hole; the other end of the blocking post is a positioning shaft 2b, and the positioning shaft passes through the through hole, and cooperates with the mark on the top of the internal nut to realize the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com