Processing technology and processing equipment of high-smoothness corrosion-resistant high-strength stainless steel wire for ship

A processing technology, stainless steel technology, applied in the field of high-gloss, corrosion-resistant, high-strength stainless steel wire processing technology and its processing equipment for ships, can solve the problems of large deformation, low precision of wire slots, and damage to the surface finish of wire rods, etc., to reduce the frequency and power requirements, energy-saving equipment purchase cost, and the effect of reducing equipment purchase cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

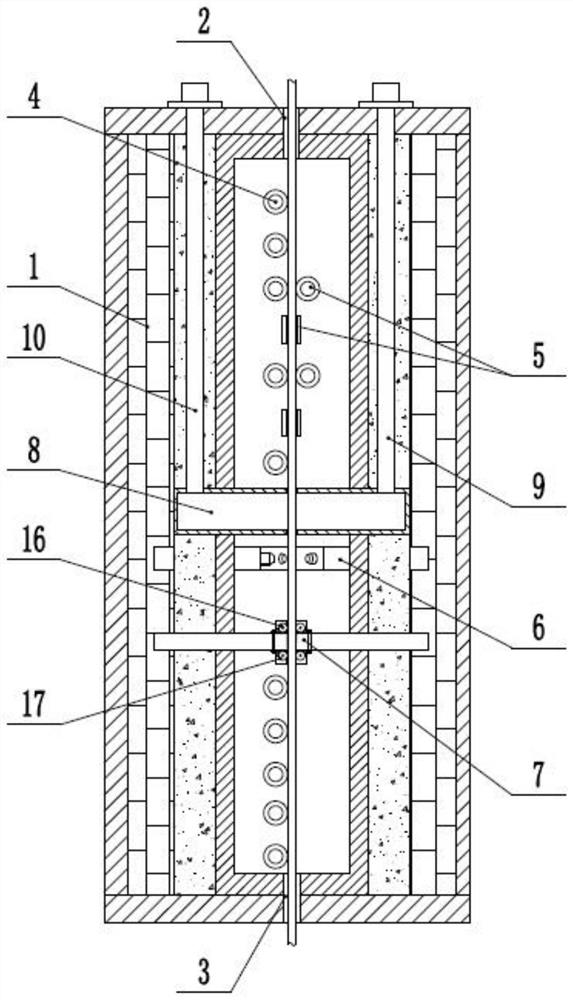

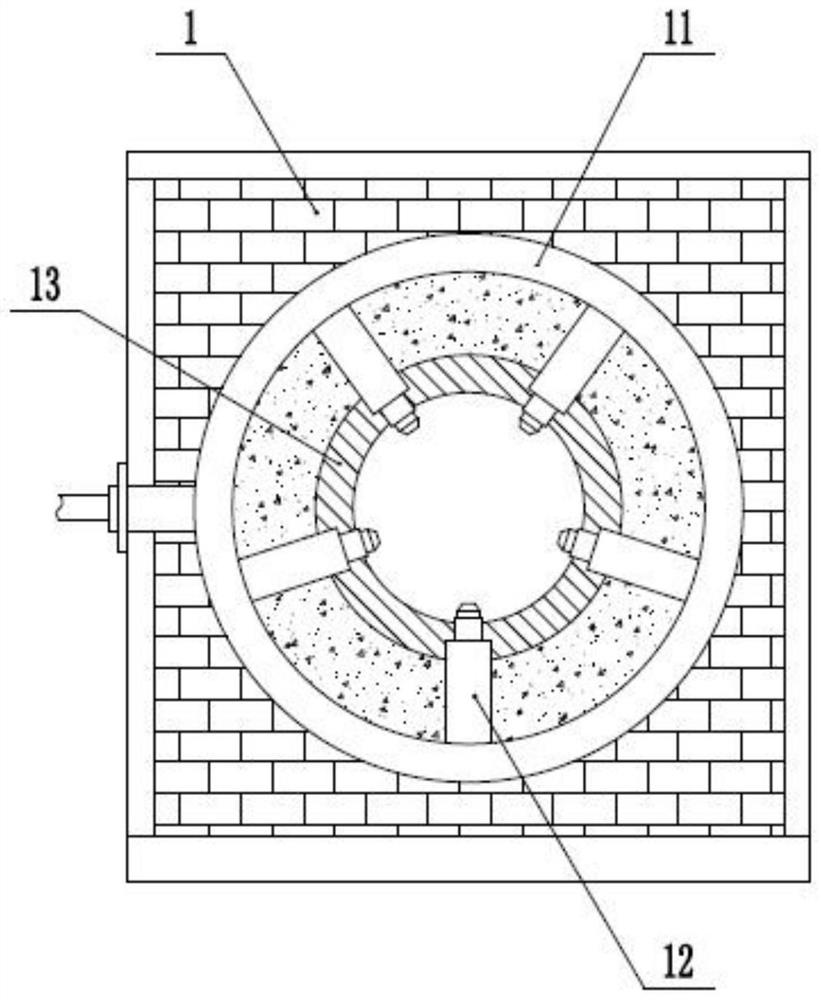

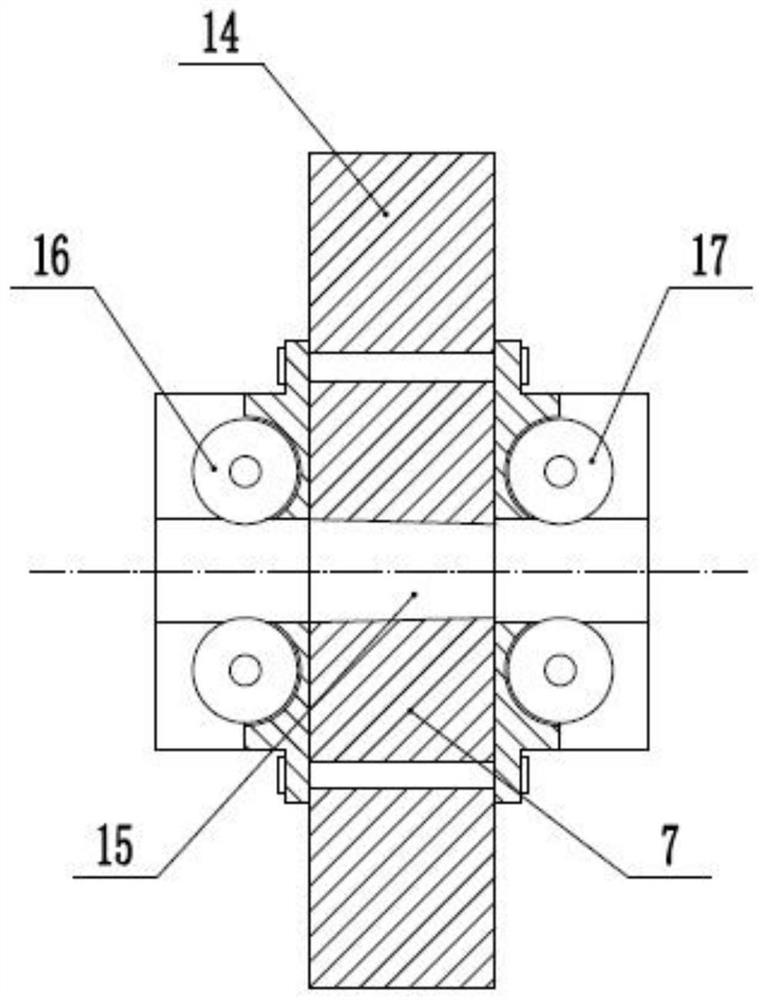

[0038] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

[0039] A process for processing high-gloss, corrosion-resistant, high-strength stainless steel wire rods for ships, comprising the following steps:

[0040] Step 1. The stainless steel wire processed by the laying machine is cooled to 1100°C by air cooling, and sent to a solid solution furnace for solid solution treatment;

[0041] In step one, the temperature of the furnace body of the solid solution furnace is maintained at 1080°C ± 10°C;

[0042] In step 1, the stainless steel wire is an austenitic stainless steel wire;

[0043] Step 2, the stainless steel wire rod is straightened in the solid solution furnace body, and the stainless steel wire rod after straightening is reheated in the solid solution furnace body;

[0044] In step 2, the high-temperature gas obtained by cooling the stainless stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com