EGR cooler digital core automatic assembling machine and main control system thereof

A technology of EGR cooler and assembly machine, which is applied in the direction of metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of automatic compression assembly of inconvenient devices, automatic mechanical clamping of inconvenient devices, and automatic transmission of inconvenient materials, so as to achieve easy operation , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

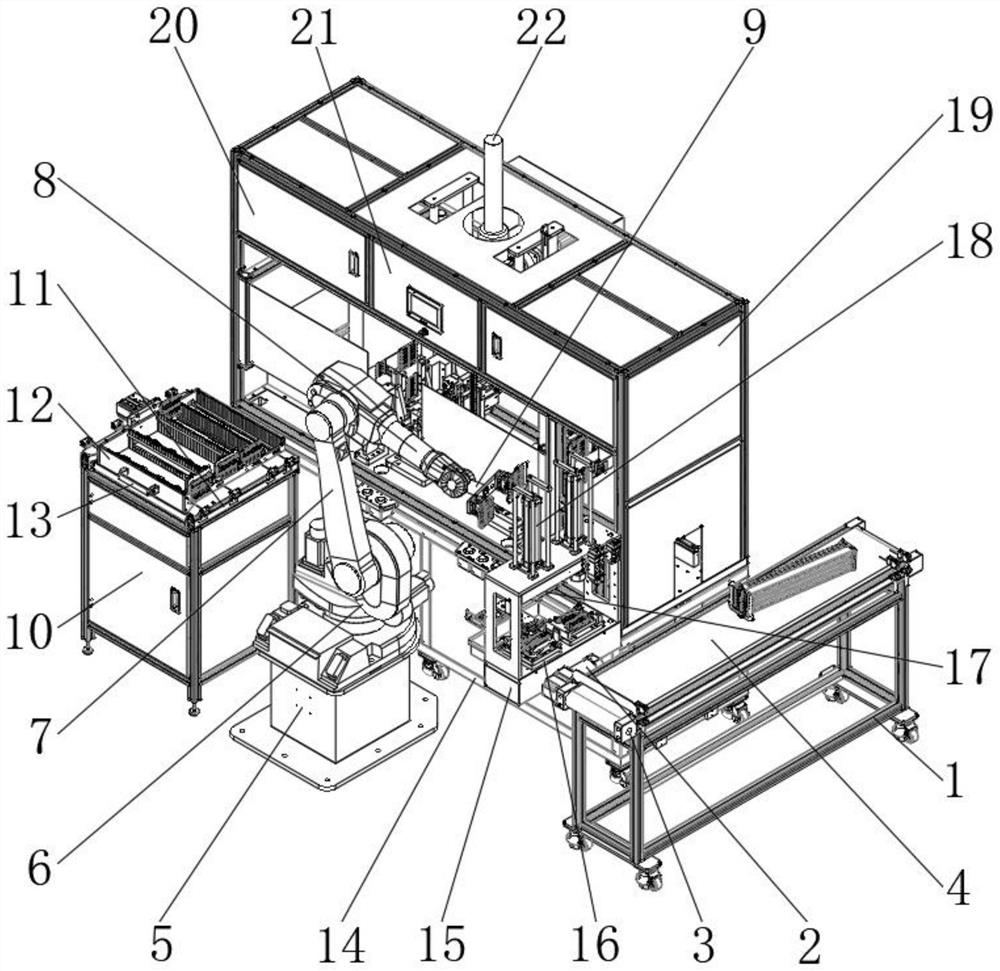

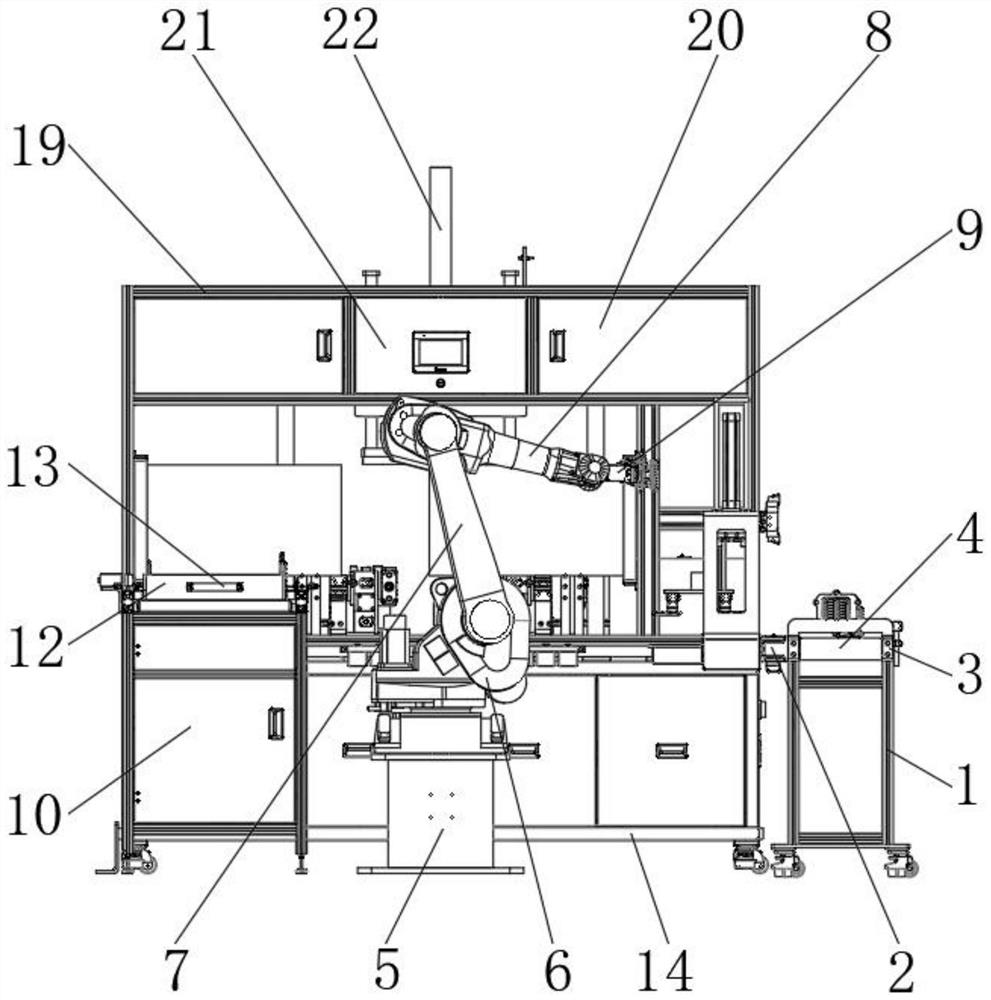

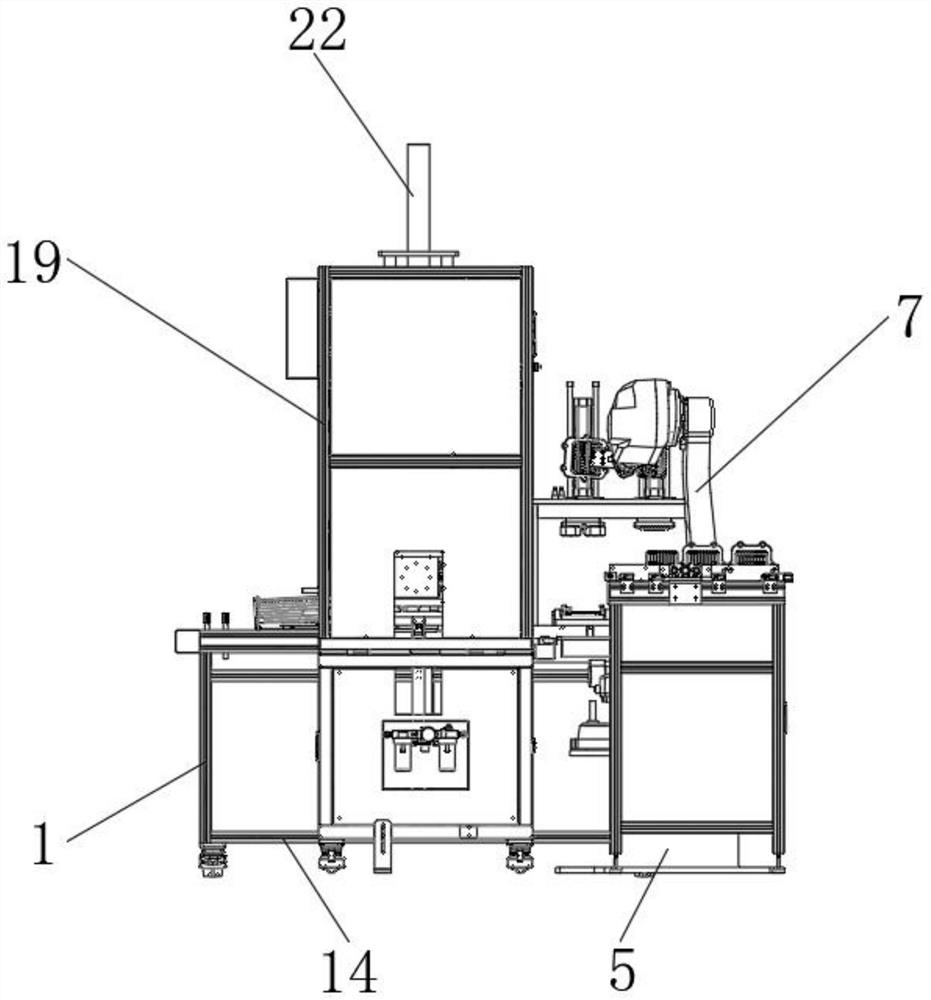

[0033] see Figure 1-4 As shown, the EGR cooler digital core automatic assembly machine includes a conveying frame 1 and a bottom box 14, a servo motor 2 is installed at the end of the conveying frame 1, and a roller head 3 is installed at the end of the servo motor 2, and the roller The outside of the gear head 3 is provided with a transmission belt 4, the side of the conveyor frame 1 is provided with a fixed seat 5, and the top of the fixed seat 5 is provided with a movable frame 6, and the top of the movable frame 6 is connected with a first mechanical arm 7, and the second The end of a mechanical arm 7 is connected with the second mechanical arm 8, and the end of the second mechanical arm 8 is equipped with a connecting gripper 9, the side of the fixed base 5 is provided with a placement cabinet 10, and the top of the placement cabinet 10 is provided with There is a sliding frame 11 , a storage drawer 12 is provided on the inner side of the sliding frame 11 , and a handle ...

Embodiment 2

[0038] see Figure 1-5 As shown in Comparative Example 1, as another embodiment of the present invention, the bottom box 14 is arranged on the side of the storage cabinet 10, and the inside of the bottom box 14 is provided with a processing frame 15, and the inside of the processing frame 15 is provided with a placement seat 16 , and the top of the placement seat 16 is provided with a lower pressing plate 17, and the end of the lower pressing plate 17 is equipped with a telescopic cylinder 18, the top of the bottom box 14 is provided with a main frame 19, and the side of the main frame 19 is provided with a movable drawer 20, The side of movable drawer 20 is provided with maintenance plate 21, and the inner side of maintenance plate 21 is provided with elevator 22, and the end of elevator 22 is provided with circular protective cover 23, and the bottom of circular protective cover 23 is provided with core assembly pressing plate 24. A guide post 25 is provided on the side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com