Package printing device with drying function

A packaging printing and functional technology, applied in the field of packaging and printing devices with drying function, can solve the problems of reducing drying efficiency, material damage, reducing the quality of packaging paper, etc., achieving convenient use, avoiding partial drying, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

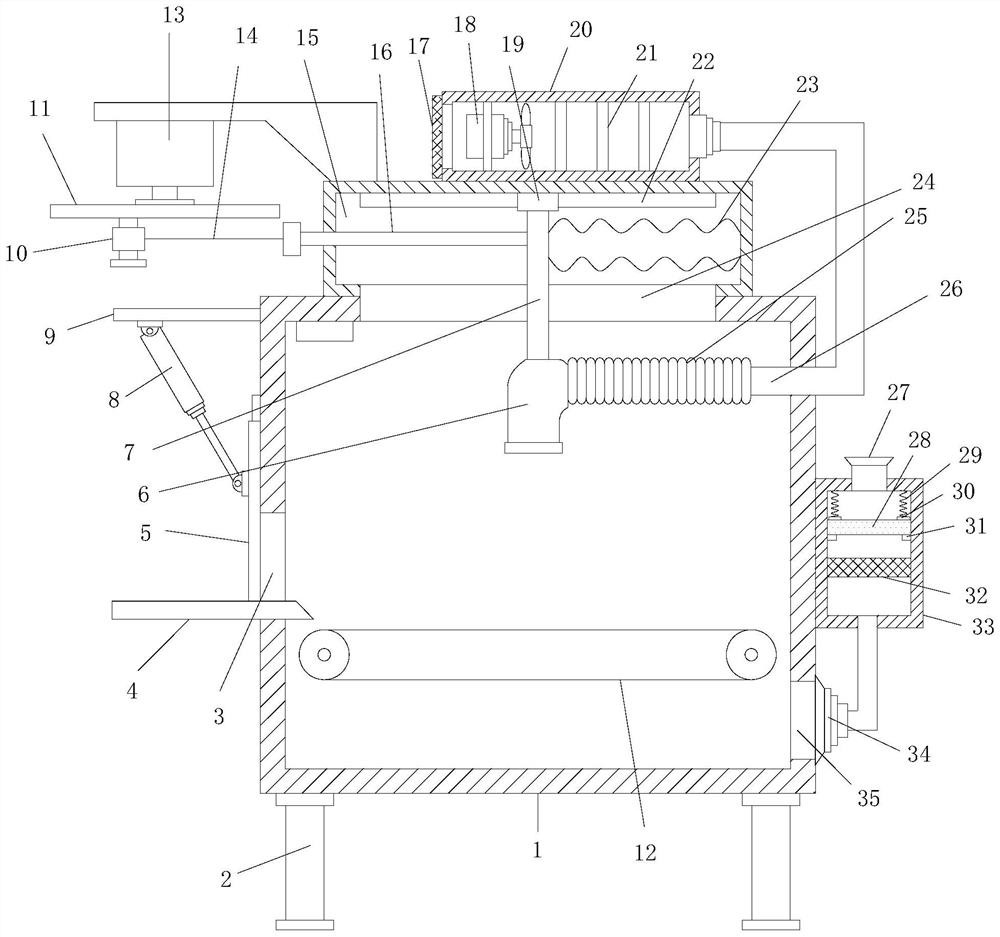

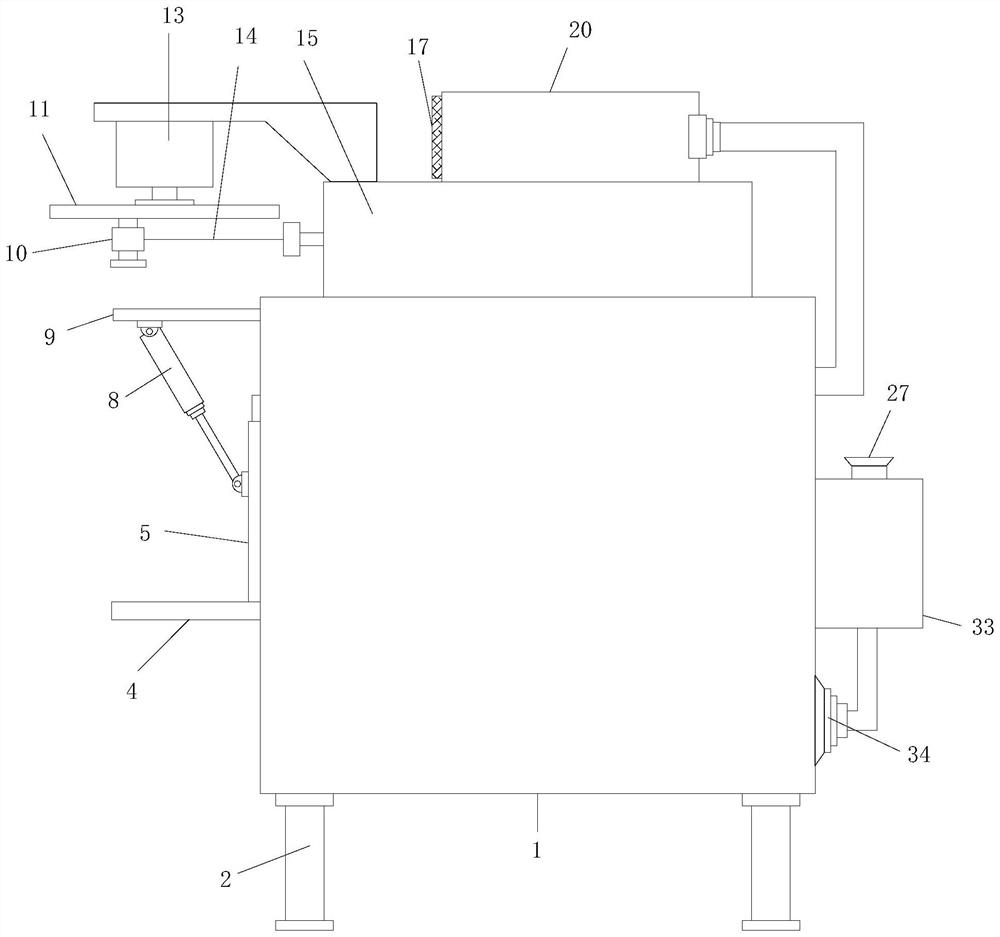

[0019] Example 1: See Figure 1~2 , a packaging and printing device with a drying function, comprising a drying box 1, a plurality of support columns 2 are fixedly connected to the bottom surface of the drying box 1, and a conveyor belt 12 is installed inside the drying box 1, so that The left end surface of the drying box 1 is provided with a material opening 3, and the middle part of the upper end surface of the drying box 1 is fixedly connected with a fixed box 15, and a communication opening 24 is provided between the fixed box 15 and the drying box 1. The inner wall of the opening 24 is slidably connected with a slide plate 7, the bottom end surface of the slide plate 7 is fixedly connected with the air spray head 6, and the right end surface of the drying box 1 is fixedly connected with a fixed pipe 26, and the fixed pipe 26 is connected with the air spray head 6. A bellows 25 is connected between them, and a bellows 20 is fixedly connected to the right side of the upper...

Embodiment 2

[0026] Example 2: See Figure 1~2 , a packaging and printing device with a drying function, the difference from Embodiment 1 is that a filter box 33 is fixedly connected above the right end surface of the drying box 1, and a conduit is fixedly connected to the bottom end surface of the filter box 33, The free end of conduit is fixedly connected with collection cover 34, and described collection cover 34 is fixedly connected at air outlet 35 places, and the inside of described filter box 33 is respectively provided with filter screen 32 and active carbon filter plate 28, and described filter box 33 An exhaust pipe 27 is fixedly connected to the upper end surface.

[0027] Further, the inner, left and right side walls of the filter box 33 are fixedly connected with several support blocks 31, the activated carbon filter plate 28 is placed on several support blocks 31, and the left and right sides of the upper end surface of the activated carbon filter plate 28 are all attached to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com