Suspension structure and vehicle

A suspension and link mechanism technology, applied in the field of vehicles, can solve the problems of reduced vibration isolation performance, inability to increase the diameter of the bushing, and increased stiffness, and achieve the effect of improving the vibration isolation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

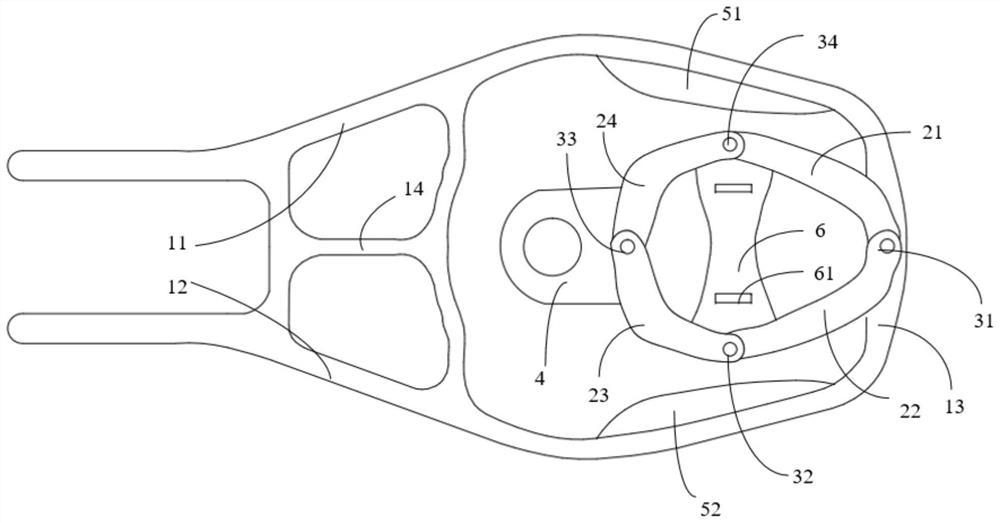

[0046] figure 1 is a schematic structural diagram of a suspension structure according to an embodiment of the present invention. The suspension structure may generally include an active end bracket, a passive end bracket 4, a double rocker mechanism and an elastic element. The active end bracket is connected to the passive end bracket 4 through a double rocker mechanism, and the active end bracket is connected to the powertrain. The end bracket 4 is fixed on the vehicle body or the sub-frame; the double rocker mechanism includes four connecting rods arranged in a diamond shape, and adjacent connecting rods are connected by hinges.

[0047] In this embodiment, the active end bracket includes a first bracket part 11, a second bracket part 12 and a third bracket part 13, wherein the third bracket part 13 is U-shaped, and the first bracket part 11 and the second bracket part 12 are respectively connected At both ends of the third support portion 13 , both the first support portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com