Composite material automobile threshold and preparation method thereof

A composite material and threshold technology, applied in the direction of vehicle parts, upper structure, upper structure sub-assembly, etc., can solve the problems of high manufacturing cost, large intrusion, technical difficulties in process methods and connection schemes, and achieve process freedom High, realizable, improved crash performance and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0041] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0042] In the present invention, unless otherwise clearly specified and limited, terms such as "installation", "connection", "connection" and "fixation" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection , or integrated; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components or the interaction relationship between two components, unless otherwise specified limit. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

[0043] In the present i...

Embodiment 2

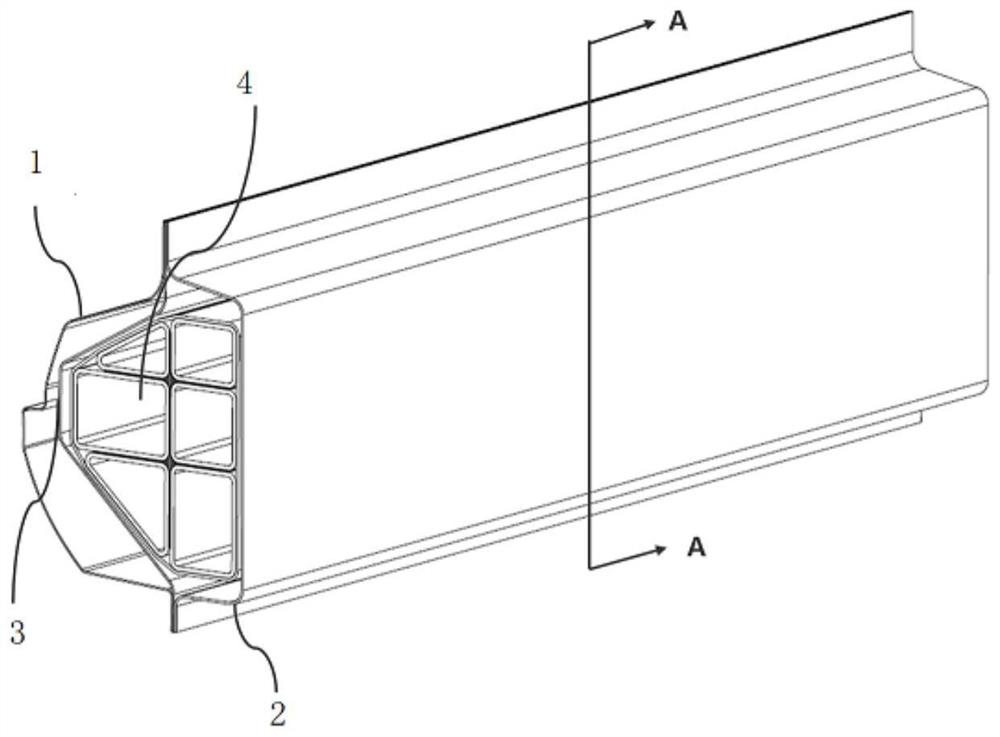

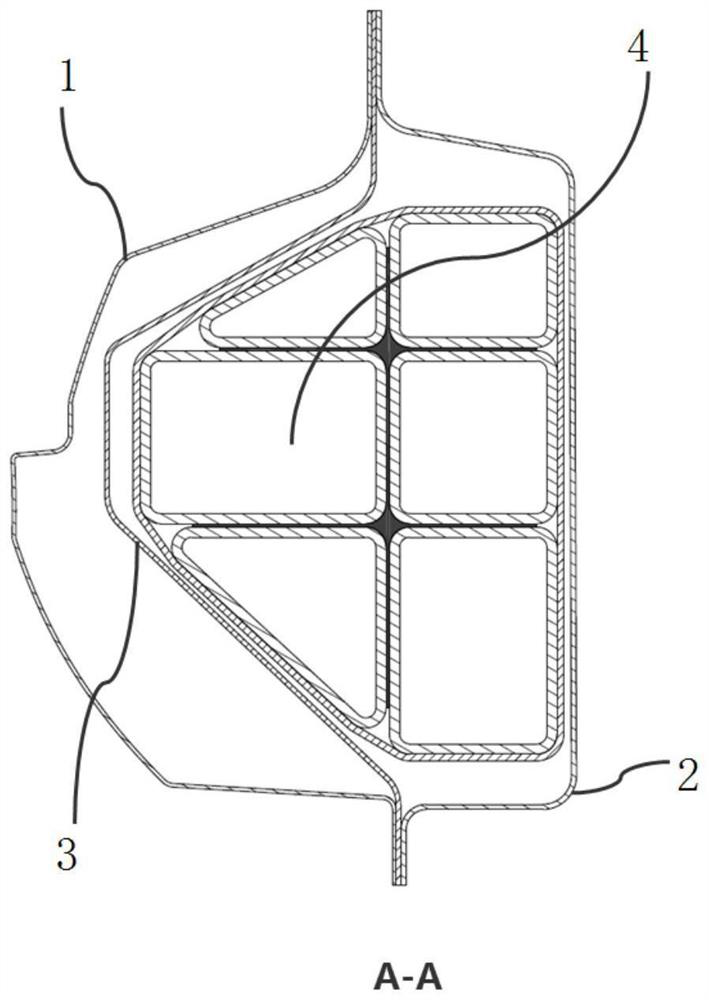

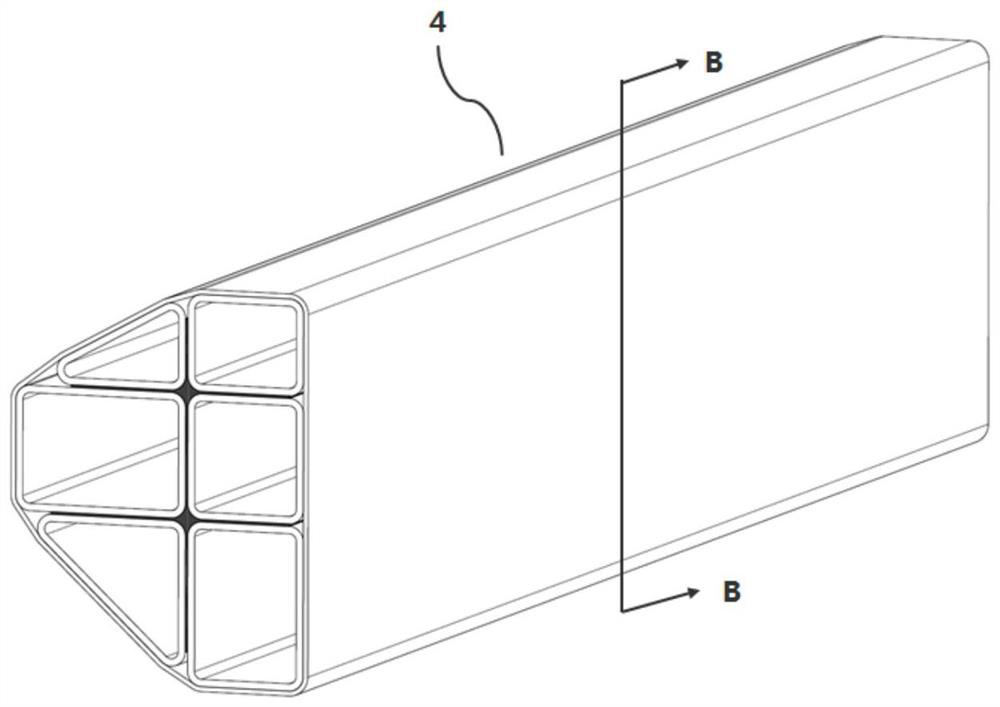

[0053] like figure 1 and figure 2 As shown, this embodiment provides a composite material automobile door sill, which can achieve better side impact performance of the vehicle body, and at the same time has a good lightweight effect and low manufacturing cost, including the outer panel 1, the inner panel 2, the inner panel The reinforcement plate 3 and the reinforcement beam 4, the outer panel 1 and the inner panel 2 are enclosed to form a threshold beam with a hollow cavity inside, the inner panel reinforcement plate 3 and the reinforcement beam 4 are arranged in the cavity, and the inner panel reinforcement plate 3 is tightly Paste the reinforcing beam 4, the reinforcing beam 4 is composed of an outer tube 41 and a core tube bundle, the core tube bundle is composed of a plurality of core tubes with different or the same cross-sectional shape, the core tube bundle is located in the outer tube 41, and the core tube bundle The outer surface is in close contact with the inner ...

Embodiment 3

[0056] This embodiment provides a method for preparing a composite automobile door sill, comprising the following steps:

[0057] Step S1: preparing outer panels, inner panels and inner panel reinforcing panels;

[0058] Step S2: preparing a core tube of metal material and a core tube of continuous fiber composite material;

[0059] Step S3: preparing a core tube bundle;

[0060] Structural adhesive is applied to the two bonding surfaces of each core tube, and then the core tubes are combined and fixed together according to the set arrangement using fixtures, and then according to the characteristics of the selected structural adhesive, normal temperature or high temperature solidified to prepare a core tube bundle;

[0061] Step S4: preparing a reinforcing beam;

[0062] Using the core tube bundle in step S3 as the mandrel, using winding equipment, impregnating the continuous fiber bundle or continuous fiber tape with resin, and then winding on the surface of the core tube...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com