Metal-lined carbon fiber composite barrel and its prestressing method

A metal lining, composite material technology, applied in the direction of the body tube, metal layered products, chemical instruments and methods, etc., can solve the waste of materials, the combination is not tight, the carbon fiber composite material layer can not play a role in strengthening the circumferential strength of the body tube and other problems, to achieve the effect of delaying the development process, reducing weight, and facilitating the pressing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

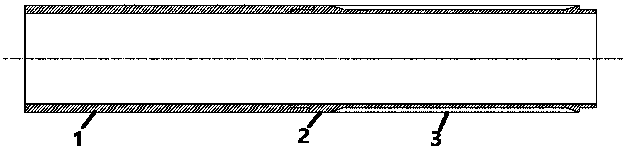

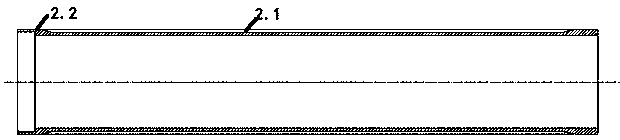

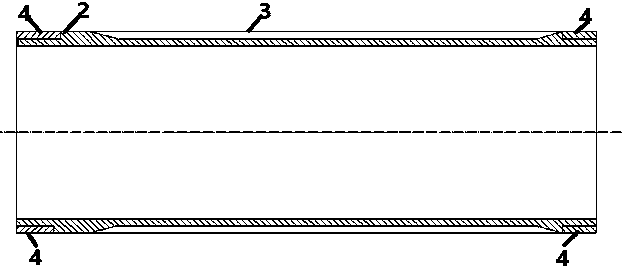

[0018] Such as Figures 1 to 3 As shown, the barrel in the present embodiment includes several metal linings 2 and carbon fiber composite material layers 3 and metal tail pipes 1 equal to the number of metal linings, and the two ends of each metal lining 2 are respectively provided with (inside, Outer) connecting thread 2.2, a number of metal linings 2 are sequentially connected through the thread end to end, the metal tail pipe 1 is connected with the end metal lining 2, and the outer circumference of the metal lining 2 is formed with an annular groove 2.1, a carbon fiber composite material One pair is wound in the annular groove 2.1 of each metal lining 2 to form the aforementioned carbon fiber composite material layer 3, and the carbon fiber composite material layer 3 always has a tendency to circumferentially compress the metal lining 2, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com