Anchoring method of carbon fiber composite cable

A composite material and anchoring method technology, applied in bridge parts, erection/assembly of bridges, bridges, etc., can solve the problems of fracture of reinforcement, difference in modulus and friction performance, uneven stress of reinforcement in cross-section of anchorage, etc. , to achieve the effect of relieving stress peak, uniform performance and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

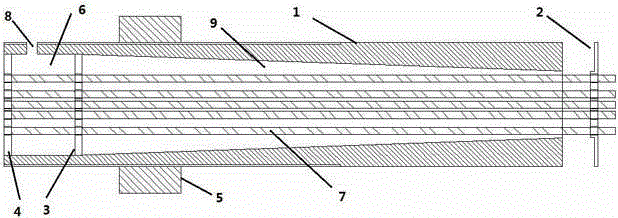

[0025] see figure 1 , the present invention relates to an anchoring method for a carbon fiber composite cable, firstly setting the carbon fiber composite ribs 7 at both ends of the carbon fiber composite cable in the anchors at both ends, and then performing horizontal grouting in the anchor at one end Then carry out vertical grouting, and then also carry out horizontal grouting first and then vertical grouting in the anchorage at the other end.

[0026] The structure of the anchorage is as follows. The anchorage includes a steel sleeve 1, a front-end splitter plate 2 of the anchorage, a first splitter plate 3 at the rear end of the anchorage and a second splitter plate 4 at the rear end of the anchorage. The outer surface of the anchorage has Thread, the thread on the outer surface of the anchor is covered with a nut 5, and there is a first cavity 6 in the steel sleeve 1 between the first split plate 3 at the rear end of the anchor and the second split plate 4 at the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com