Feeding device and method for multi-feeding Czochralski single crystal process

A feeding device and technology of multiple feeding, applied in the direction of single crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problem of lowering the quality of single crystal, reduce the wire breakage rate, improve the survival rate of the pilot and release and the whole process. Rod rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

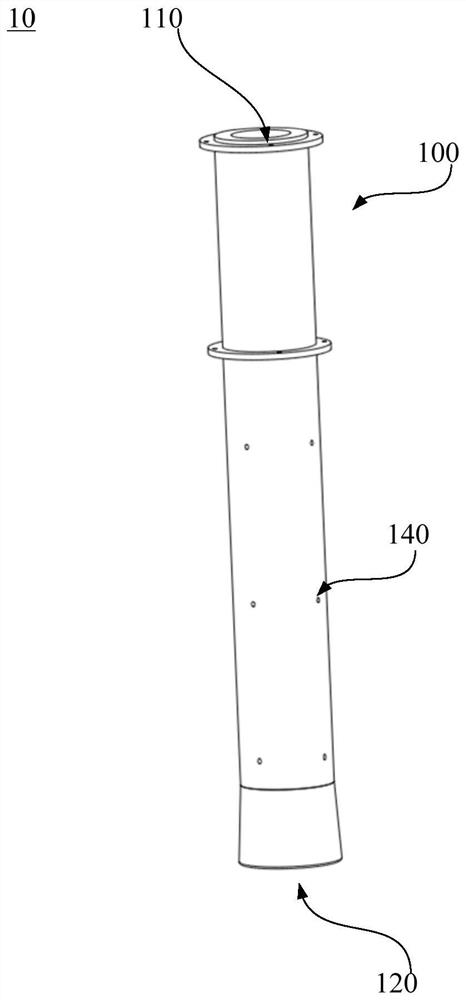

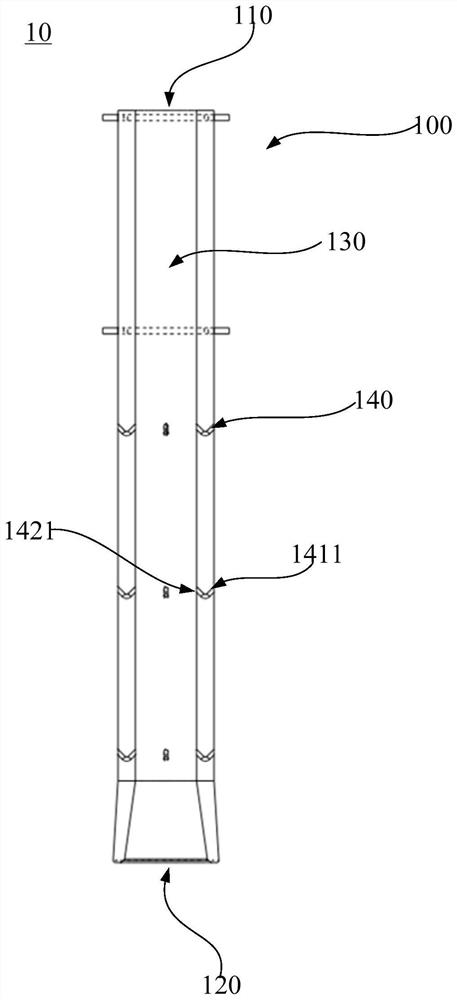

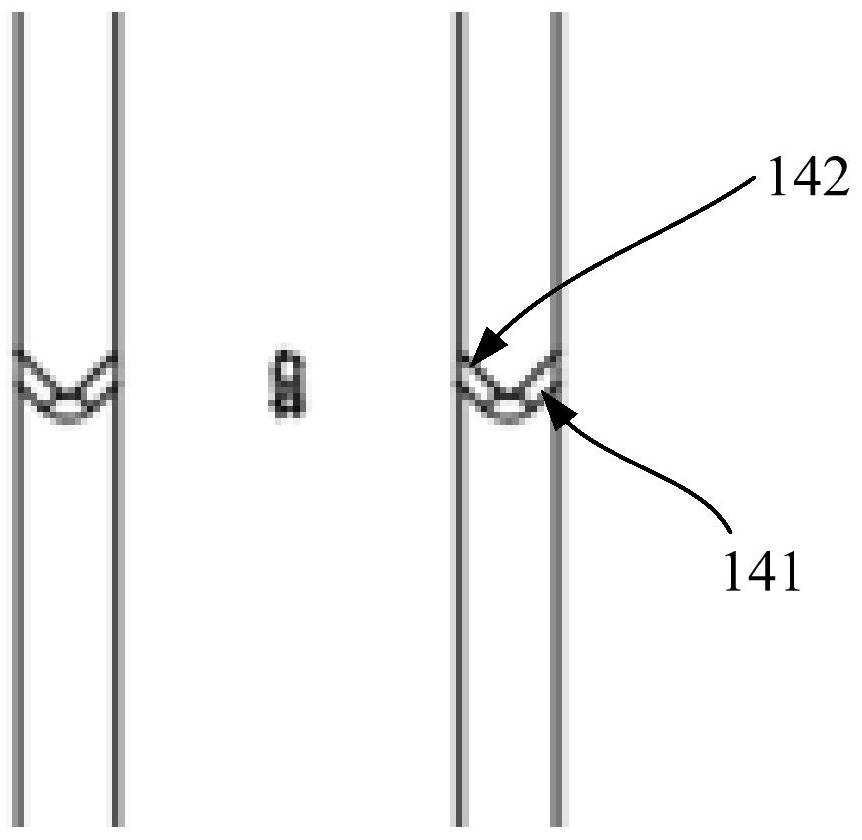

[0078] This embodiment provides a feeding device for a multi-feeding Czochralski single crystal process. The feeding device has a feeding cylinder, and the feeding cylinder is made of quartz material. The feeding barrel has a feed end and a discharge end oppositely arranged. The side wall of the feeding barrel is provided with a first air hole, the first air hole has an air inlet and an air outlet, the air inlet is located on the outer wall of the feeding barrel, the air outlet is located on the inner wall of the feeding barrel, and the first air hole is used for self-feeding outside the feeding barrel. Gas is blown to the inside of the feeding cylinder, and the gas outlet direction of the gas outlet of the first air hole is biased towards the feed end.

[0079] The first air hole includes a first air channel and a second air channel. The air inlet is located in the first airway, and the air outlet is located in the second airway. The first airway communicates with the seco...

Embodiment 2

[0082] This embodiment provides a feeding device for a multi-feeding Czochralski single crystal process. The feeding device has a feeding cylinder. The feeding cylinder is made of quartz material. The feeding barrel has a feed end and a discharge end oppositely arranged. The side wall of the feeding barrel is provided with a first air hole, the first air hole has an air inlet and an air outlet, the air inlet is located on the outer wall of the feeding barrel, the air outlet is located on the inner wall of the feeding barrel, and the first air hole is used for self-feeding outside the feeding barrel. Gas is blown to the inside of the feeding cylinder, and the gas outlet direction of the gas outlet of the first air hole is biased towards the feed end.

[0083] The first air hole includes a first air channel and a second air channel. The air inlet is located in the first airway, and the air outlet is located in the second airway. The first airway communicates with the second ...

Embodiment 3

[0086] This embodiment provides a feeding device for a multi-feeding Czochralski single crystal process. The feeding device has a feeding cylinder, a jacket structure and a first blowing mechanism, and the feeding cylinder is made of quartz material. The feeding barrel has a feed end and a discharge end oppositely arranged. The side wall of the feeding barrel is provided with a first air hole, the first air hole has an air inlet and an air outlet, the air inlet is located on the outer wall of the feeding barrel, the air outlet is located on the inner wall of the feeding barrel, and the first air hole is used for self-feeding outside the feeding barrel. Gas is blown to the inside of the feeding cylinder, and the gas outlet direction of the gas outlet of the first air hole is biased towards the feed end.

[0087] The first air hole includes a first air channel and a second air channel. The air inlet is located in the first airway, and the air outlet is located in the second ai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com