Movable efficient asphalt stirring equipment for road and bridge construction

A kind of mixing equipment and asphalt technology, which is applied in the field of road and bridge construction, can solve the problems of inconvenient stone screening, low construction efficiency, and inconvenient discharge speed, etc., achieve the effect of diversifying mixing methods, improving construction efficiency, and improving mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

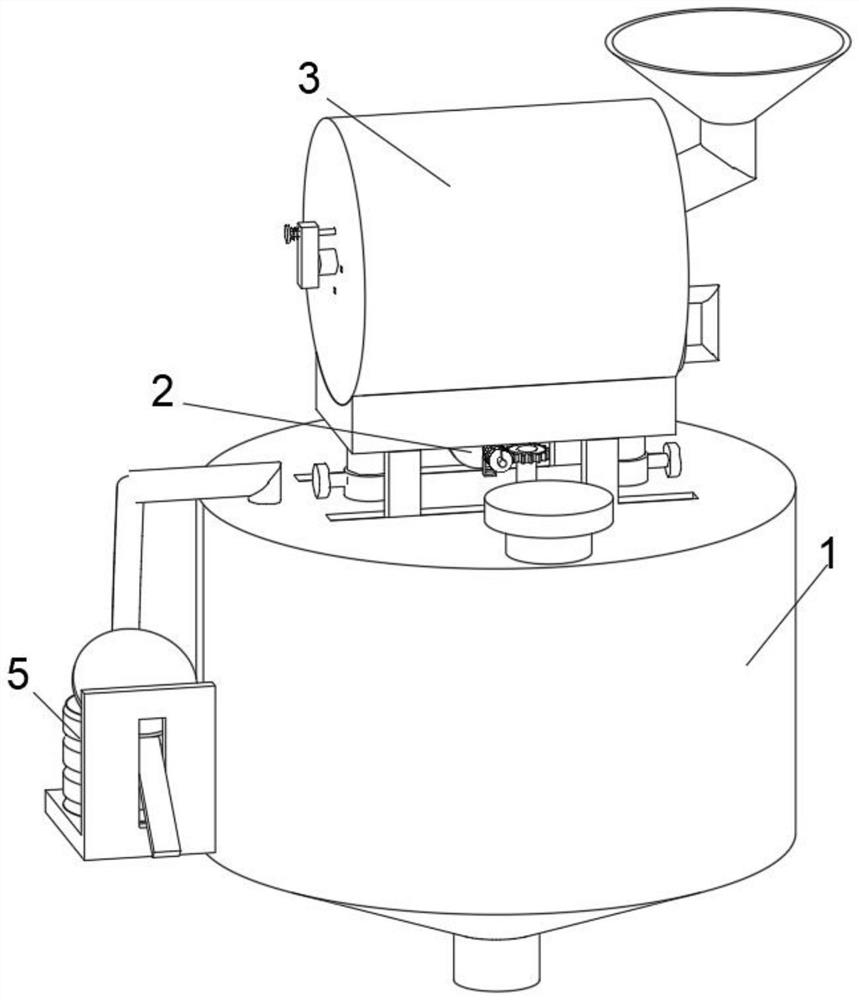

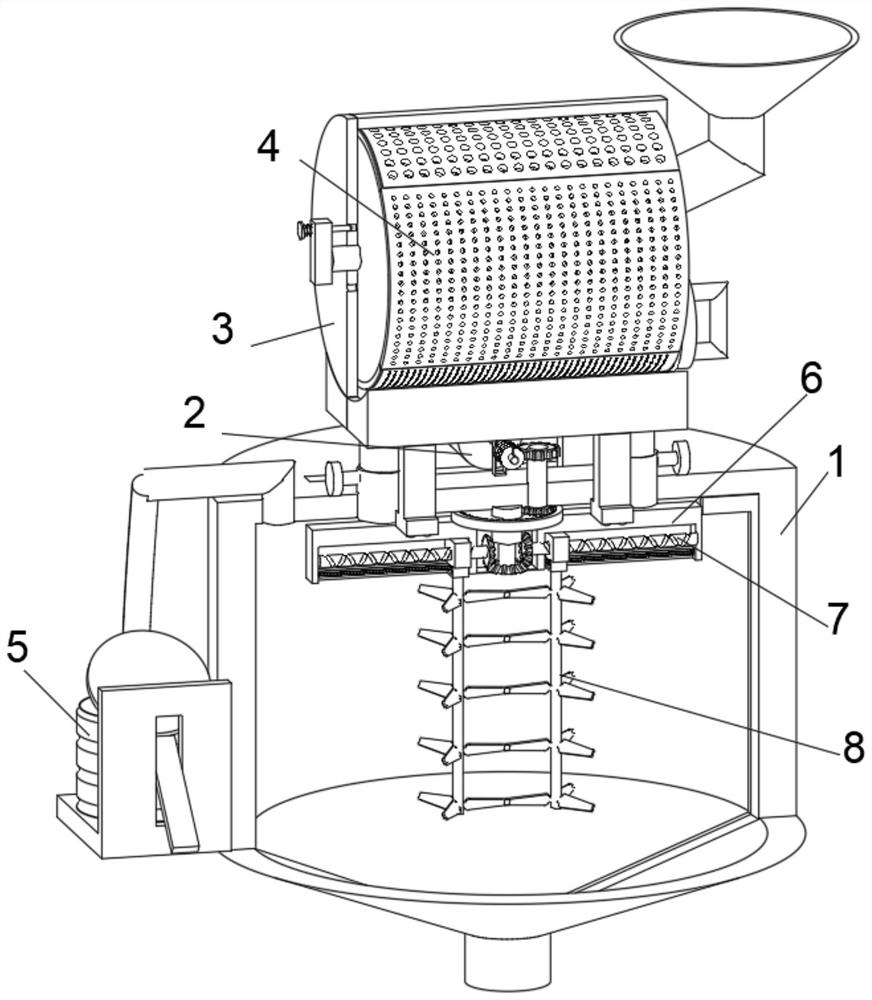

[0029] Please refer to Figures 1-6, the present invention provides a technical solution:

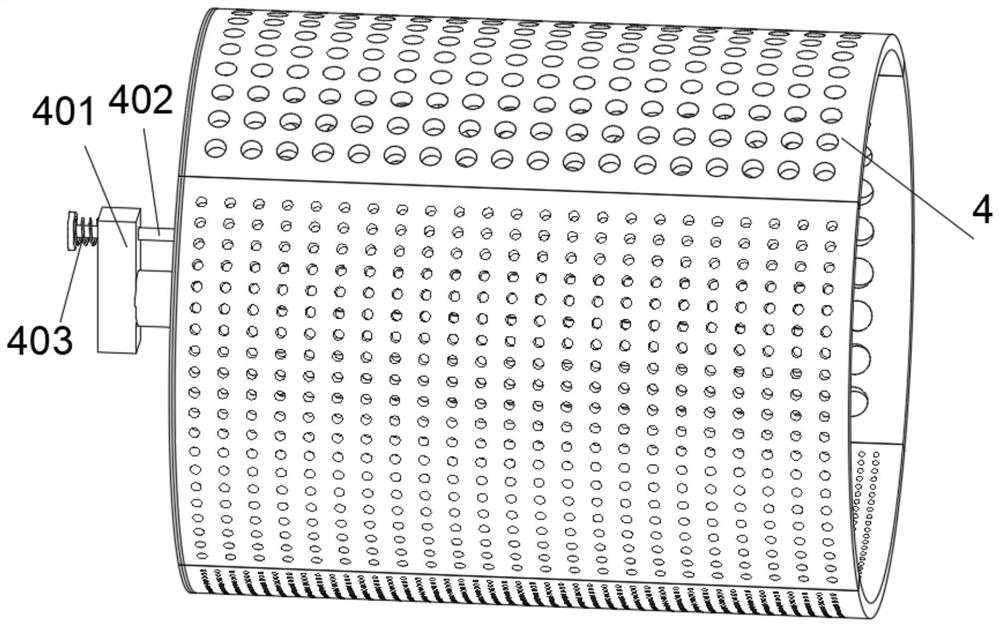

[0030] A movable asphalt high-efficiency mixing equipment for road and bridge construction, including a mixing tank 1, a motor 2 is fixedly connected to the top of the mixing tank 1, a sieve bucket 3 is arranged above the mixing bucket 1, and a sieve hopper is arranged inside the sieve bucket 3 4. There is a pressurizing component 5 on the right side of the lower end of the mixing tank 1, and a rotating seat 6 is provided on the inner wall of the upper end of the mixing tank 1. The inner wall of the rotating seat 6 has a symmetrical structure and is provided with two transmission components 7, and the lower side of the transmission component 7 is provided with a stirring component. 8.

[0031] Specifically, the top surface of the mixing bucket 1 has a symmetrical structure and is provided with two limiting grooves 101, the top surface of the mixing bucket 1 has a symmetrical structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com