Omnidirectional anti-sound measure construction structure and construction method

A construction method and construction technology, applied in building structure, building components, indoor acoustics, etc., can solve the problems of inability to quickly convert sound-reflecting panels, high cost of materials and installation, cumbersome and troublesome adjustment process, etc., to increase the sound-reflecting effect. , The effect of saving construction time and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

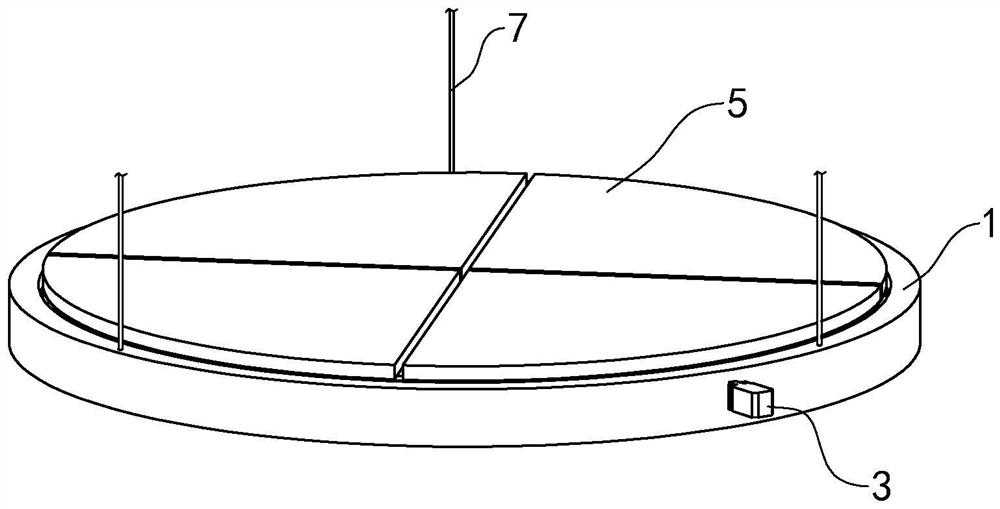

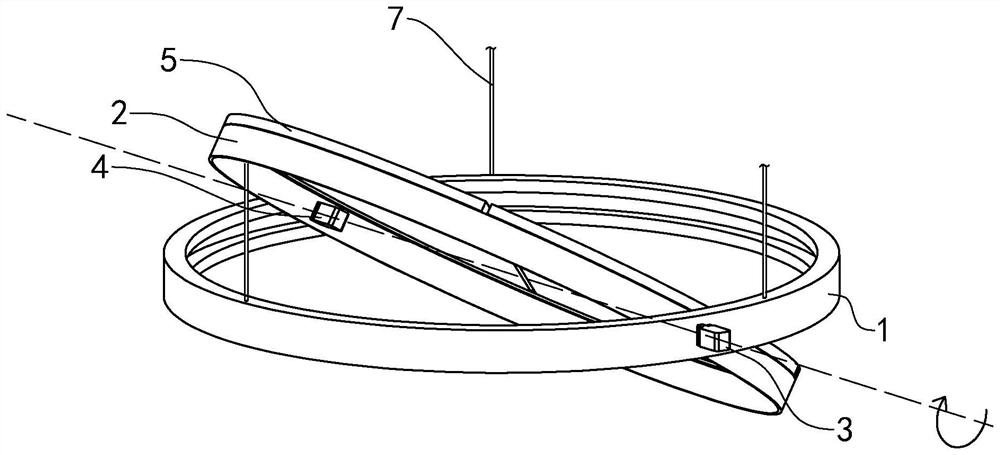

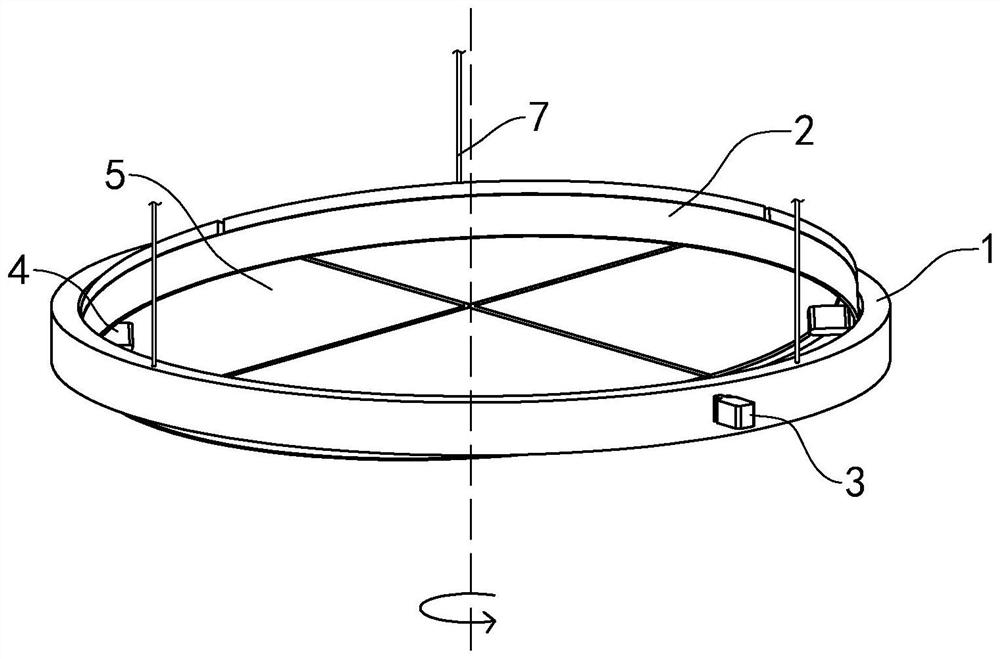

[0035] refer to Figure 1 to Figure 4 , which is an omnidirectional anti-sound measure structural structure disclosed in the present application, including a horizontal limit ring 1, a steering structure ring 2 and an anti-sound plate 5, the steering structure ring 2 is arranged on the inner wall of the horizontal limit ring 1, and the anti-sound plate 5 is fixedly arranged on the side of the steering construction ring 2. The inner wall of the horizontal limit ring 1 is provided with an auxiliary walking assembly, which drives the steering structure ring 2 to rotate and the anti-sound plate 5 to rotate horizontally, so that the anti-sound plate 5 can adjust the direction in the horizontal direction. The steering structure ring 2 is provided with a connector connecting the horizontal limit ring 1, and the connector is provided with a pair and is located on the diagonal of the steering structure ring 2. The steering structure ring 2 is rotated with the diagonal as the axis, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com