Precise worm and gear

A worm gear and worm, precision technology, applied in the direction of gear transmission, gear lubrication/cooling, belt/chain/gear, etc., can solve the problems of high relative sliding speed between meshing gear teeth, large friction loss, and low precision of worm gear, etc. To achieve the effect of ensuring the working accuracy and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

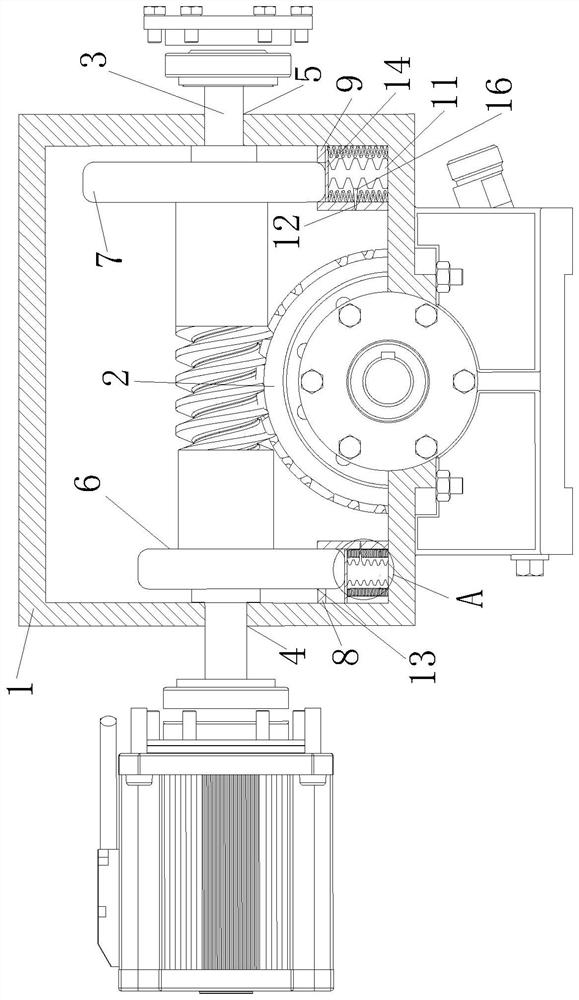

[0034] As a specific embodiment of the present invention, the extrusion assembly includes a No. 1 cam 6 and a No. 2 cam 7; the No. 1 cam 6 and the No. 2 cam 7 are fixedly connected to both sides of the worm 3;

[0035] The worm gear 2 and the worm 3 start to work, and the worm 3 starts to rotate under the drive of the motor, and at the same time drives the No. 1 cam 6 and the No. 2 cam 7 fixedly connected to both sides of the worm 3 to rotate, and the worm 3 transmits the power of the engine to the No. 1 cam 6 and The No. 2 cam 7 makes the No. 1 cam 6 and the No. 2 cam 7 start to work for extruding, thereby extruding the cooling assembly.

[0036] As a specific embodiment of the present invention, the cooling assembly includes No. 1 airbag box 8 and No. 2 airbag box 9; No. 1 airbag 10 and No. 2 airbag box 9 are fixedly installed inside the No. 1 airbag box 8 and No. 2 airbag box 9 No. 1 airbag 11; the No. 1 airbag 10 and the No. 2 airbag 11 are fixedly connected with an air no...

Embodiment approach

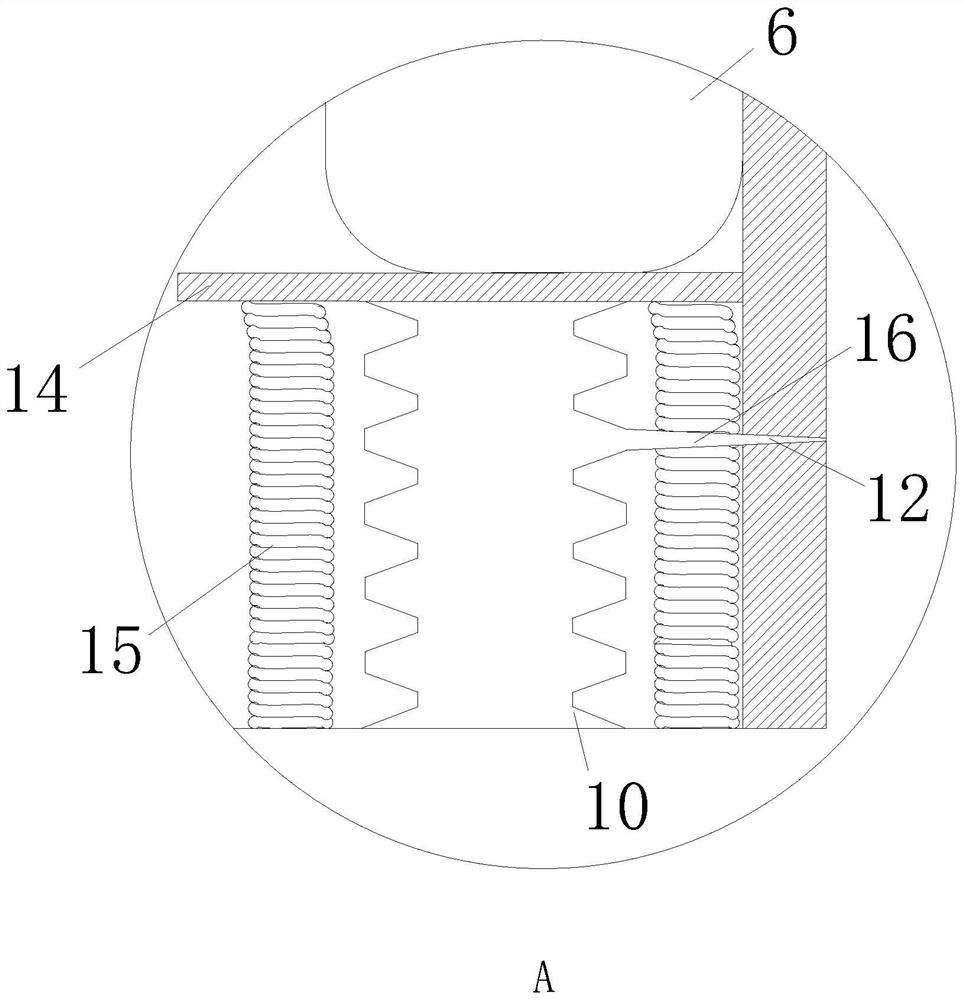

[0044] As a specific embodiment of the present invention, the four corners of the lower end of the baffle plate 14 are respectively fixedly connected with springs 15; the bottom end of the spring 15 is fixedly connected with the support frame 1;

[0045] The spring 15 fixedly connected to the lower end of the baffle plate 14 utilizes the elastic force of the spring 15 to further slow down the impact force of the first cam 6 and the second cam 7 on the first airbag 10 and the second airbag 11, and the spring 15 can be on the first cam 6 at the same time. And the second cam 7 turns away from the No. 1 airbag 10 and the No. 2 airbag 11 and rebounds to help the baffle plate 14 to reset quickly. No. 1 airbag 10 and No. 2 airbag 11 re-inhale the speed, ensure that No. 1 airbag 10 and No. 2 airbag 11 end inhalation before being squeezed next time, thereby guarantee the normal carrying out of airbag blowing heat dissipation work.

[0046] As a specific embodiment of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com