High-reliability module system

A reliability and module technology, applied in the loss prevention measures of lighting devices, lighting and heating equipment, light sources, etc., can solve the problems of reduced reliability of LED modules, failure of LED modules, dark crack safety distance, etc. Achieve the effect of avoiding poor assembly and optical anomalies, avoiding hidden anomalies, and realizing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

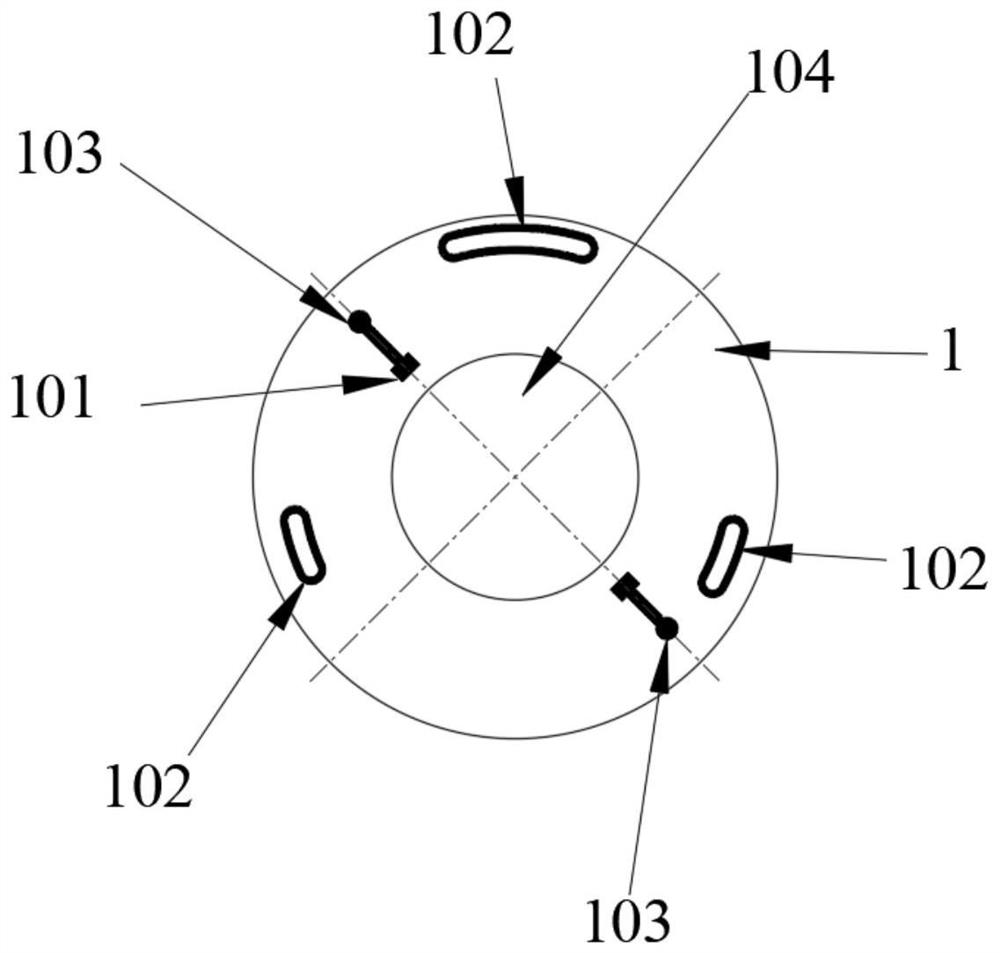

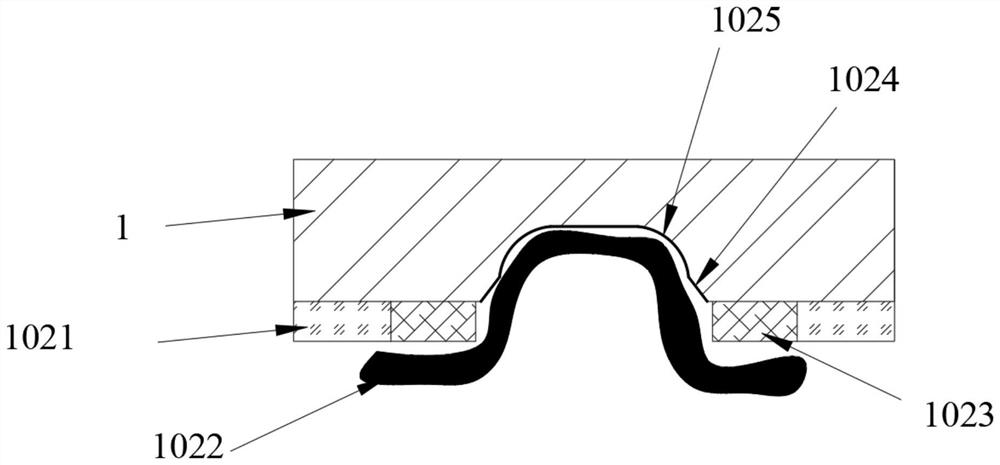

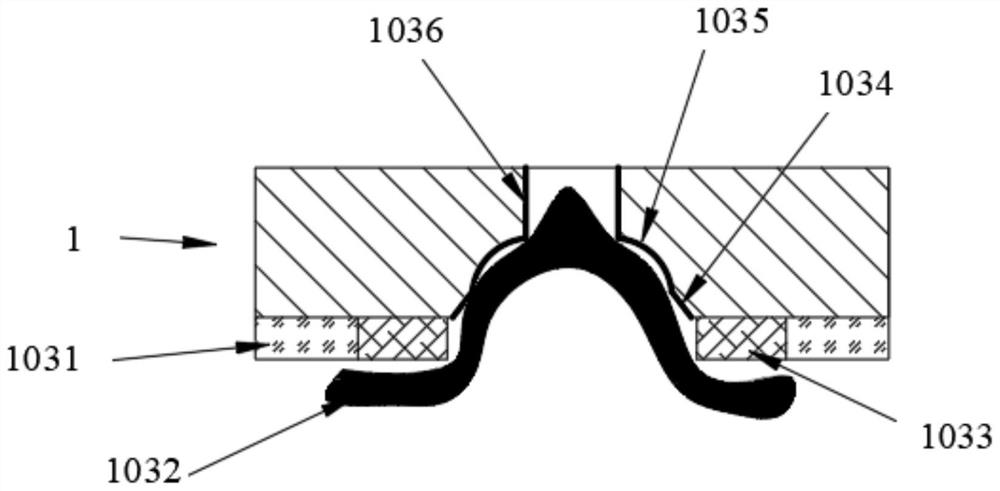

[0032] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0033] A system and its implementation method that can improve the reliability of LED modules described in the present invention can realize the separation of the LED integrated light-emitting module or COB light source from the base, and avoid the coaxiality tolerance between the components. The failure caused by too large can effectively control the coaxiality accuracy between the base and the gland, as well as the LED-integrated light-emitting module or COB light source, avoid poor assembly and optical abnormalities caused by misalignment, and improve the reliability of the LED module;

[0034] It can reduce the labor cost of the assembly and manufacturing factory...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com