Warehouse management goods weighing device easy to take

A weighing device and storage management technology, applied in the direction of measuring device, detailed information of weighing equipment, weighing, etc., can solve the problems of prone to weighing errors, inconvenience, further, poor shock absorption effect, etc., to improve convenience High performance, convenient handling, and increased bearing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

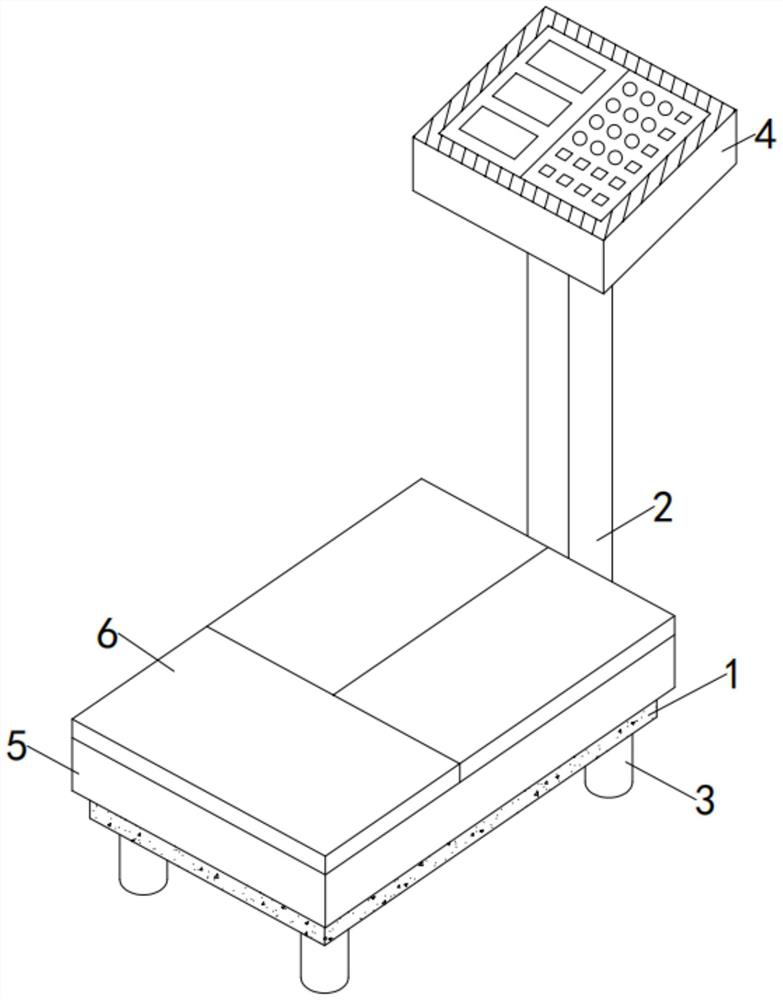

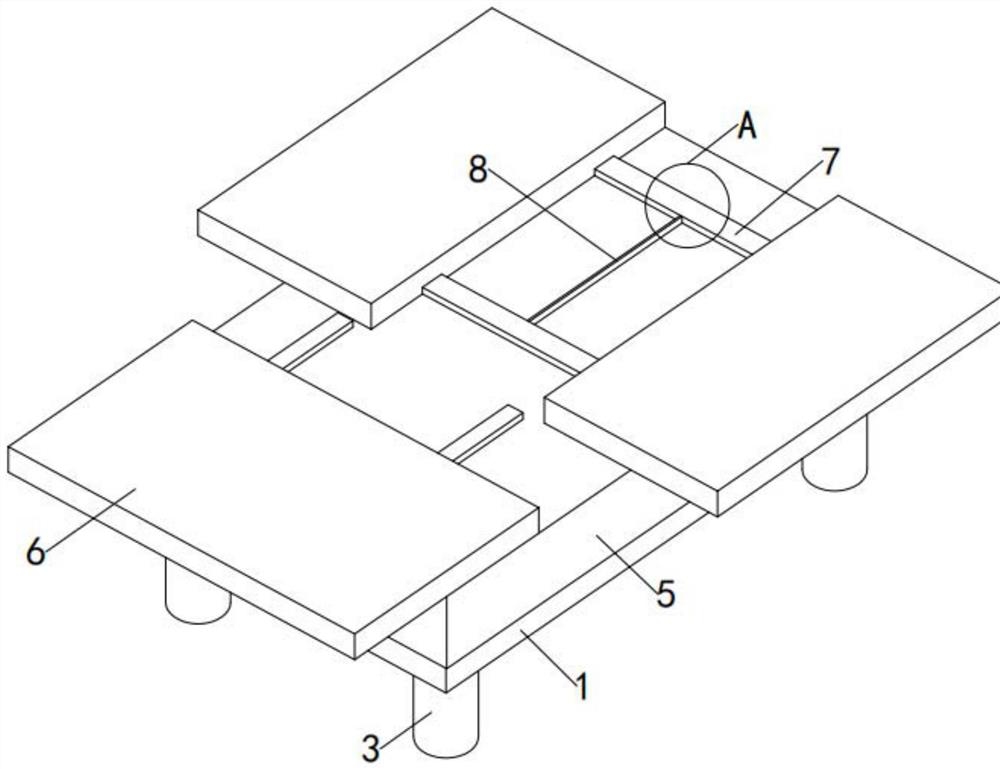

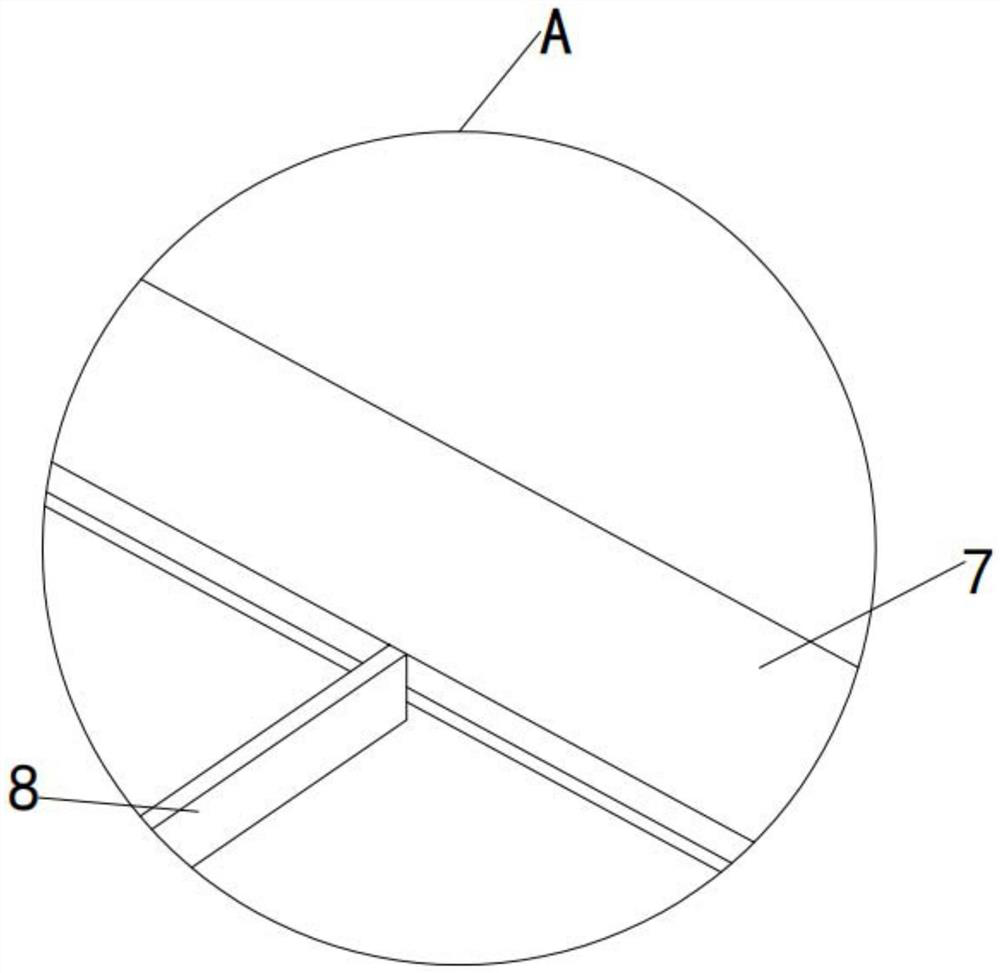

[0036] see Figure 1-4 , in the embodiment of the present invention, the top of the base 1 is nested with a force-bearing cover plate 5, the back of the base 1 is rotatably connected to the movable arm 2, the top of the movable arm 2 is nested with an operation panel 4, and the upper surface of the force-bearing cover plate 5 slides A movable plate 6 is provided, and three movable plates 6 are provided to slide on the upper surface of the stressed cover plate 5, and the sum of the areas of the three movable plates 6 is consistent with the upper surface area of the stressed cover plate 5, and the movable plate 6 slides The distance is not greater than 1 / 2 of its own width, and the sliding direction is outward sliding. The upper surface of the stressed cover plate 5 is fixedly connected with slide rails 7, and there are four slide rails 7, two of which are connected to a movable plate 6. The other two sliding rails 7 are connected to the other two movable plates 6, and the cro...

Embodiment 2

[0041] see Figure 5-6 , in this embodiment, one side of the movable plate 6 is fixedly connected with a metal tenon block 601, and the opening on one side of the other movable plate 6 matches the embedded groove of the metal tenon block 601, and the opening on one side of the metal tenon block 601 has a fixed groove, The inside of the movable plate 6 is provided with an anti-off rod 602 at the edge of the embedding groove, and the anti-off rod 602 is also an electrically controlled telescopic rod, and the anti-off rod 602 stretches out and fits into the inside of the fixed groove.

[0042] In this embodiment, when the three movable panels 6 need to be closed together, push the movable panels 6 to slide inwards until the movable panels 6 are close to each other. Synchronously, the metal tenon block 601 is snapped into the embedded groove, and the anti-locking mechanism is activated. The detaching rod 602 makes it protrude and snaps into the inside of the fixing groove to achieve...

Embodiment 3

[0044] see Figure 7-9 , in this embodiment, the support rod 3 is embedded with an electronically controlled telescopic rod 301, the lower end of the electrically controlled telescopic rod 301 is slidably provided with a sliding rod 302, and the bottom end of the sliding rod 302 is nested with a balance board 303, and the balance board 303 is surrounded by It is fitted with the inner wall of the support rod 3. The lower surface of the balance plate 303 is rotatably connected with a connecting plate 304. The connecting plate 304 is movably connected with a scroll wheel 305 through a shaft. The inner ring 3051 is embedded in the scroll wheel 305. The scroll wheel 305 The outside is wrapped with an outer cladding 3054, and a partition plate 3053 is embedded between the outer side of the inner ring 3051 and the inner side of the outer cladding 3054, and 8 partition plates 3053 are arranged at equal angles, and an airbag ball 3052 is embedded between the partition plates 3053 , and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com