Micro leakage flow automatic detection device and detection method thereof

A technology of automatic detection and metering device, which is applied in the direction of measuring the acceleration and deceleration rate of fluid and using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problems of inconvenient leakage detection, poor detection accuracy and low efficiency, etc. Achieve a wide range of objects and working conditions, improve efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

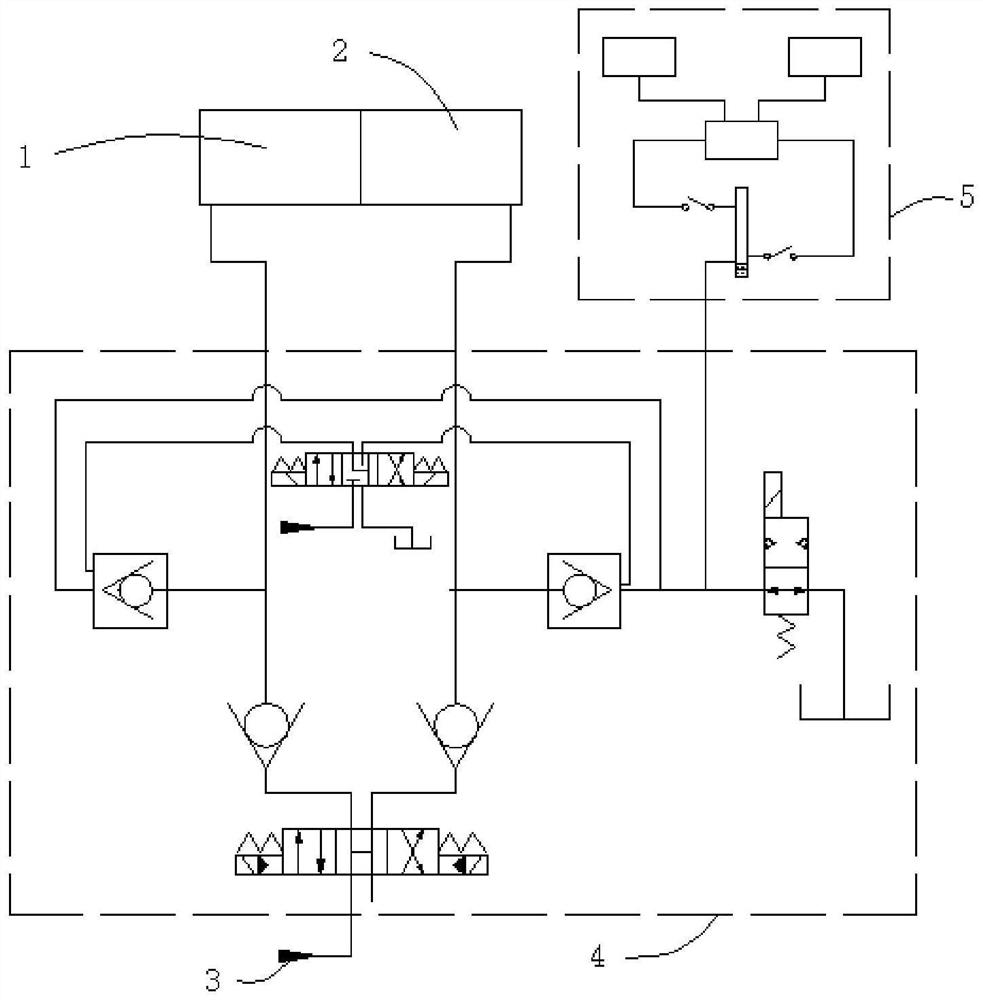

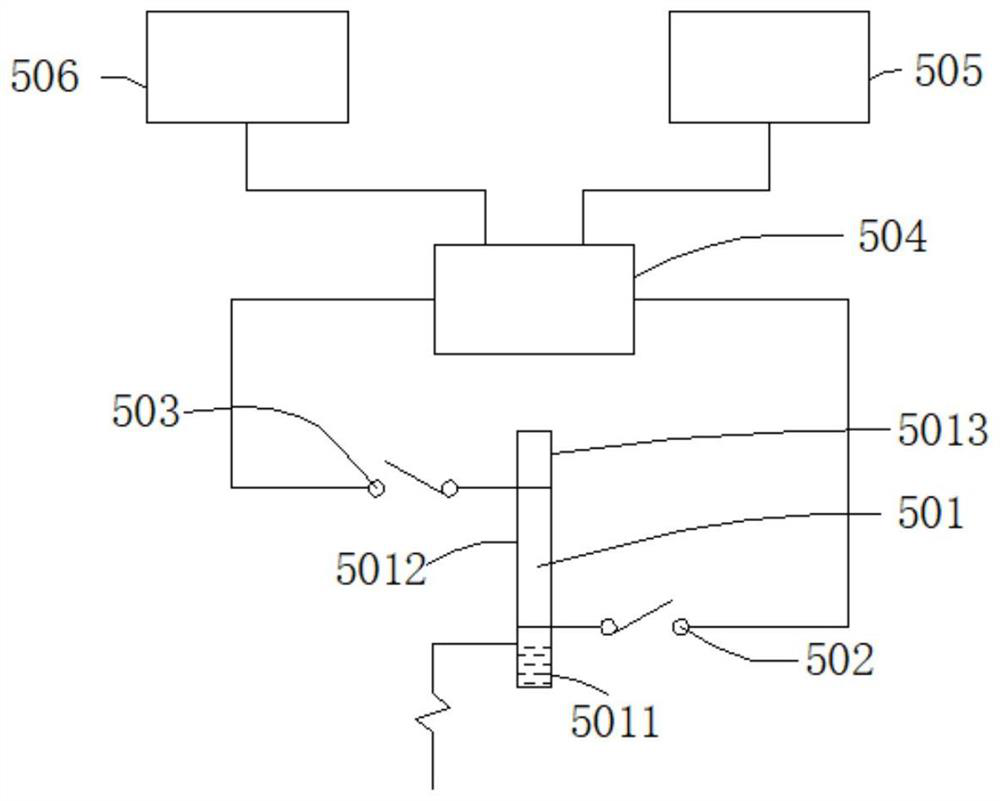

[0039] Such as figure 1 As shown, an automatic detection device for small leakage flow is used to detect the leakage rate between the first cavity 1 and the second cavity 2, including a liquid source 3, a fluid pipeline control device 4 and a metering device 5; The output end of the liquid source 3 is connected to the first cavity 1 and the second cavity 2 through a fluid pipeline;

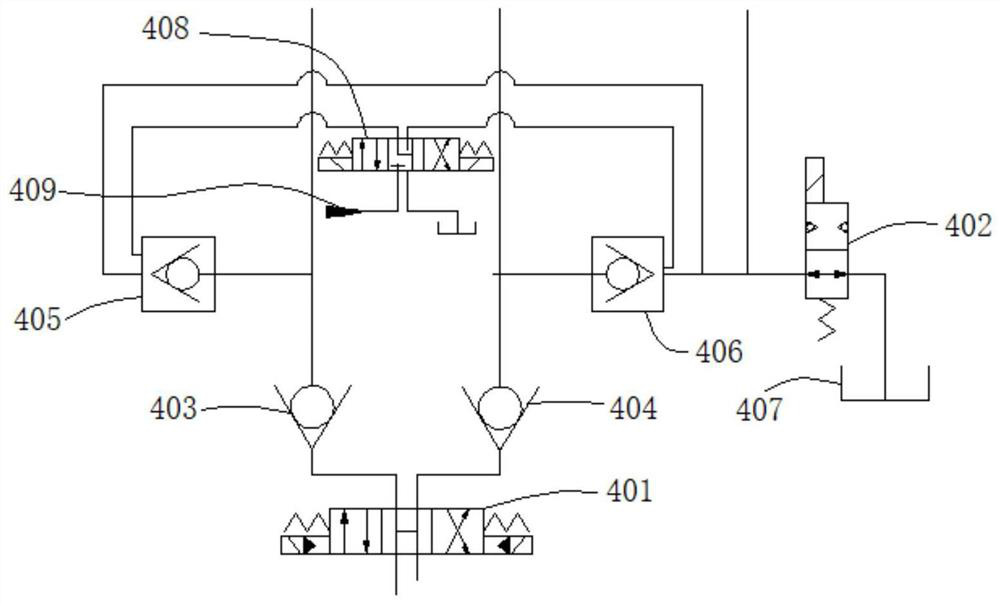

[0040] Such as figure 2 As shown, the fluid pipeline control device includes a first reversing valve 401, a solenoid valve 402, a first one-way valve 403, a second one-way valve 404, a first controllable one-way valve 405, a second controllable one-way valve 406;

[0041] The output end of the liquid source 3 is connected to the input end of the first reversing valve 401, the first outlet of the output end of the first reversing valve 401 is connected to the liquid inlet of the first one-way valve 403, and the liquid outlets of the first one-way valve 403 are respectively Access to the first c...

Embodiment 2

[0058] Such as Figure 4 As shown, this embodiment provides a detection method for an automatic detection device for micro-leakage flow, including the following steps:

[0059] S1: The liquid source 3 is started, and the power fluid is output to the first chamber 1 or the second chamber 2;

[0060] S2: The leakage fluid from the first cavity 1 or the second cavity 2 enters the metering device 5 through the fluid pipeline control device;

[0061] S3: The metering device 5 completes the metering, feeds back the metering result, and controls the solenoid valve 402 to open at the same time, and the leakage fluid is discharged to the liquid collection container 407 through the solenoid valve 402, and the detection is completed.

[0062] Step S2 includes the following two testing schemes:

[0063] When testing the leakage of the first cavity 1, the first outlet of the output end of the first reversing valve 401 is connected, and the power fluid enters the first cavity 1 through th...

Embodiment 3

[0077] The detection device and detection method of the present invention are suitable for internal leakage testing of oil cylinders, valves, motors, and pumps. This embodiment provides the application and implementation of leakage detection in hydraulic cylinders;

[0078] An automatic detection device for tiny leakage flow, used to detect the leakage rate between the first cavity 1 and the second cavity 2, including a liquid source 3, a fluid pipeline control device 4 and a metering device 5; the liquid source 3 The output end is connected with the first cavity 1 and the second cavity 2 through a fluid pipeline;

[0079] The fluid pipeline control device 4 includes a first reversing valve 401, a solenoid valve 402, a first one-way valve 403, a second one-way valve 404, a first controllable one-way valve 405, a second controllable one-way valve 406, Liquid collection container 407, second reversing valve 408 and control oil source 409;

[0080] The output end of the liquid s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com