Lower electrode structure capable of effectively preventing Arcling and installation method thereof

An electrode structure and electrode technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of uncertainty, inability to produce insulation effect, easy damage of anodic oxidation coating, etc., and achieve the effect of cost saving and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

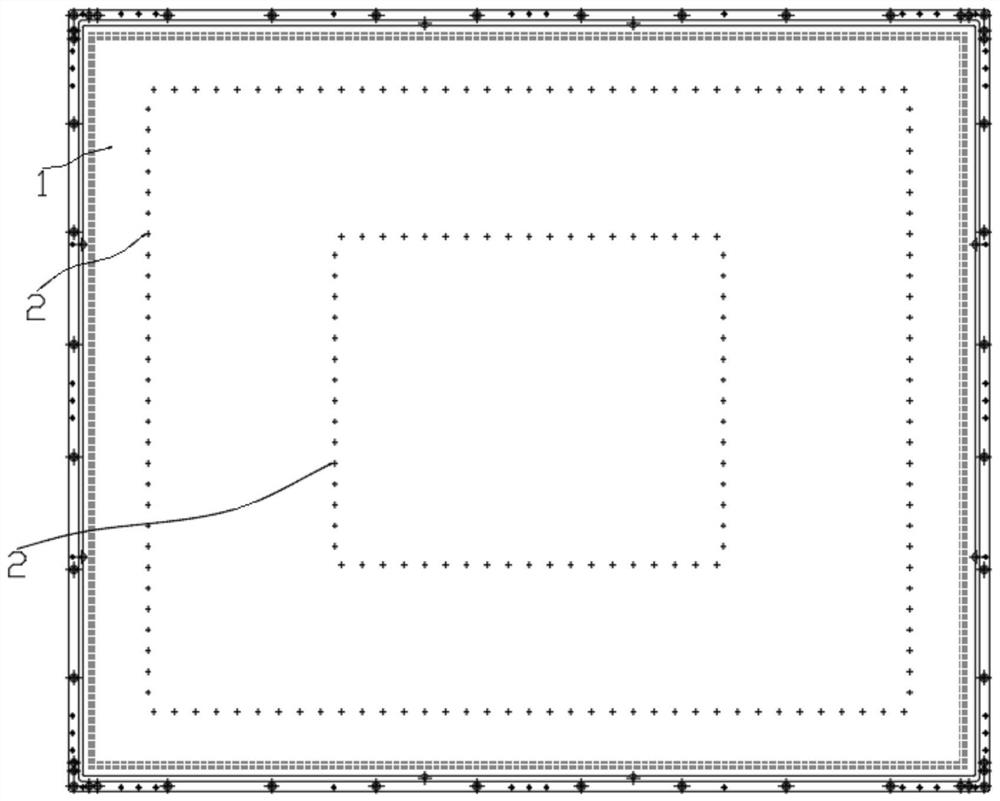

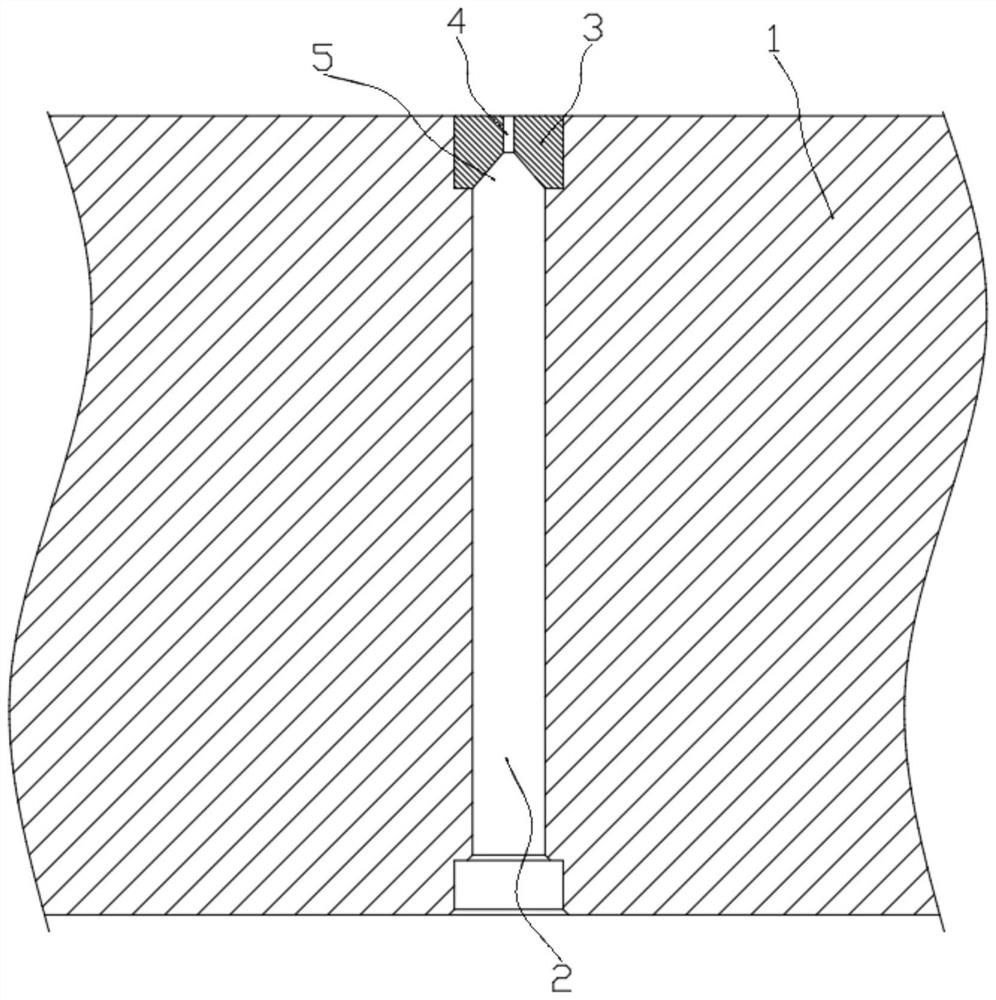

[0026] Example 1, such as Figure 1~2 As shown, the present invention is a lower electrode structure that can effectively prevent Arcing, including an electrode main board 1, a helium hole 2 opened on the electrode main board 1, the electrode main board 1 is rectangular, and its inner side is distributed with two large and small circles arranged in a rectangular shape The helium hole 2, wherein the structure of the helium hole 2 has been improved. Specifically, an insulating block 3 is inlaid on the electrode main board 1 at one end of the helium hole 2, and a through hole 4 with a diameter smaller than the helium hole 2 is provided on the insulating block 3, and the through hole 4 Coaxially arranged at the outer end of the helium hole 2, and the through hole 4 communicates with the helium hole 2 and runs through both sides of the electrode main board 1, so that helium can pass through the helium hole 2 and pass through the through hole 4 Spray out to meet the needs of the pr...

Embodiment 2

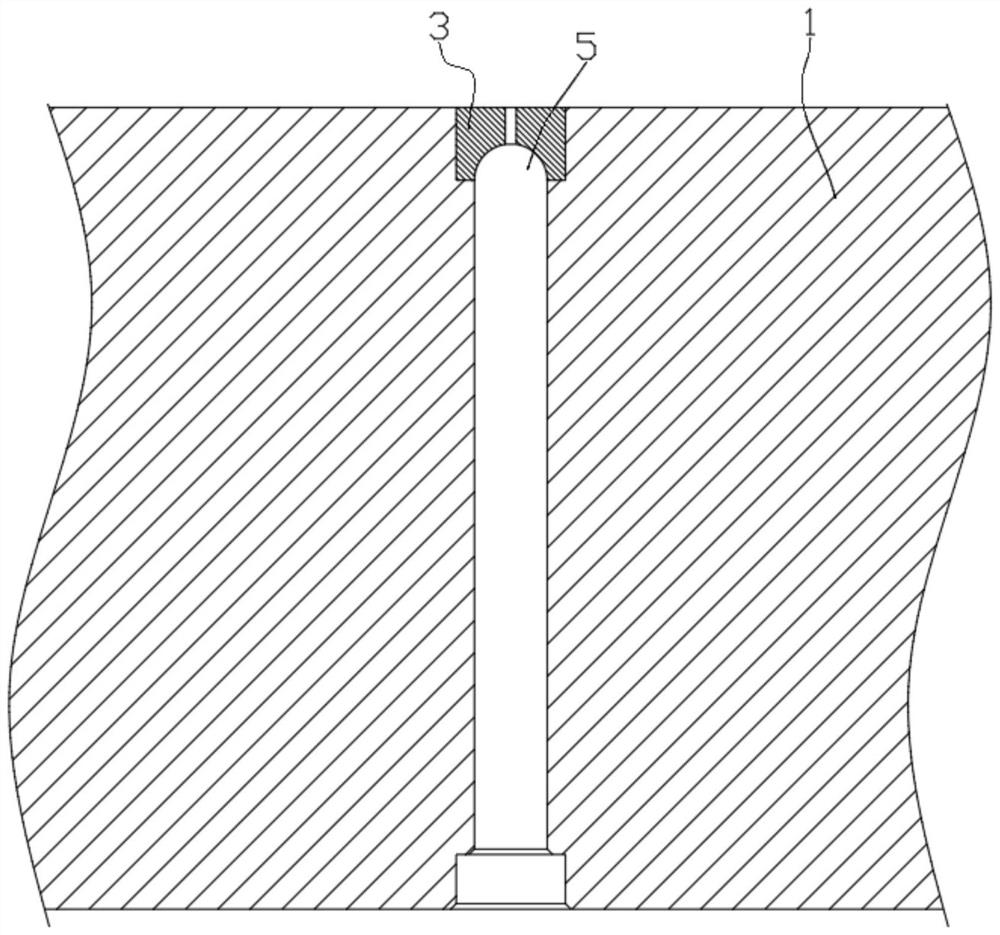

[0029] Example 2, such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the structure of the guide groove 5 is arc-shaped.

Embodiment 3

[0030] Example 3, such as Figure 4 and 5 As shown, the difference between this embodiment and Embodiment 2 is that a sealing ring 6 is provided between the insulating block 3 and the electrode main board 1, and a first hole for accommodating the sealing ring 6 is provided on the end surface of the insulating block 3. Annular groove 7, the second annular groove 8 for accommodating the sealing ring 6 is opened on the electrode main board 1, by setting the sealing ring 6, air leakage can be prevented, and the injection pressure of helium can be controlled relatively uniformly.

[0031] In this embodiment, the outer side of the insulating block 3 is provided with an auxiliary mounting block 9, and the insulating block 3 is preferably made of ceramic material, which has a good insulating function and a smooth surface, which can better guide helium, so that The helium inflow guide is more regular, so that all the flushing force is all on the ceramic material. In the case of long-t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com