Lithium battery negative electrode, preparation method thereof and lithium battery

A technology of lithium battery and negative electrode, which is applied in the field of lithium battery, lithium battery negative electrode and its preparation, can solve the problems of rapid power decay of lithium battery, and achieve the effect of high power level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

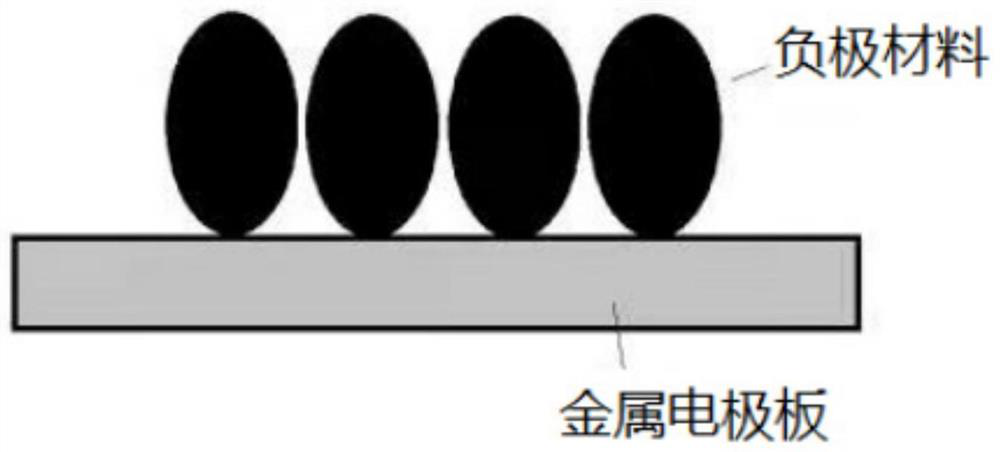

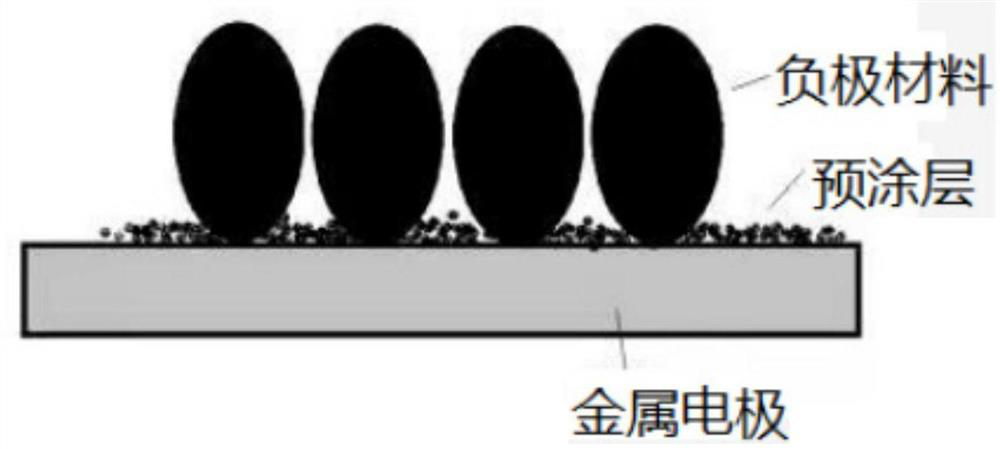

Image

Examples

preparation example Construction

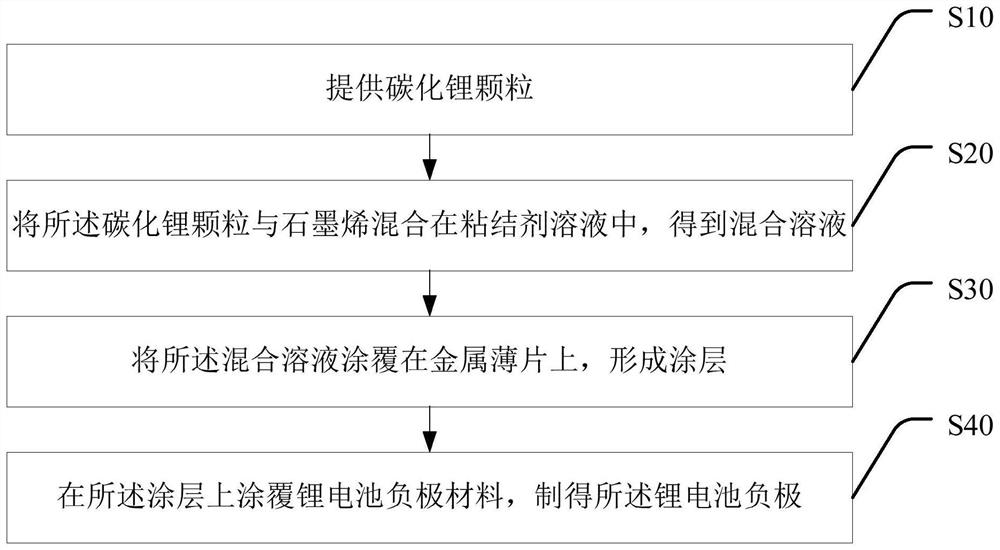

[0030] Based on this, the invention provides a kind of preparation method of lithium battery negative electrode, such as image 3 As shown, it includes the steps:

[0031] S10, providing lithium carbide particles;

[0032] S20, mixing the lithium carbide particles and graphene in a binder solution to obtain a mixed solution;

[0033] S30, coating the mixed solution on the metal sheet to form a coating;

[0034] S40. Coating the negative electrode material of the lithium battery on the coating to obtain the negative electrode of the lithium battery.

[0035] In the present invention, by providing a layer of coating between the metal sheet and the negative electrode material of the lithium battery, the coating includes lithium carbide particles and graphene, which is equivalent to pre-stored part of lithium ions in the negative electrode. During the charging process of the negative electrode of the lithium battery, due to the generation of a large number of electrons, the lit...

Embodiment 1

[0046] A kind of preparation of lithium ion battery:

[0047] The lithium carbide particles and graphene are mixed in an aqueous acrylic resin solution according to a mass ratio of 1:99 to obtain a mixed solution; the mixed solution is coated on a metal sheet to form a coating; coating on the coating Lithium metal, making lithium battery negative electrode;

[0048] The negative electrode of the lithium battery and the positive electrode LiCoO 2 Set on the left and right sides of the diaphragm, and add 1M LiPF6 EC / DEC solution as the electrolyte, and assemble it into a CR2032 button battery.

Embodiment 2

[0050] A kind of preparation of lithium ion battery

[0051] The lithium carbide particles and graphene are mixed in an aqueous acrylic resin solution according to a mass ratio of 20:99 to obtain a mixed solution; the mixed solution is coated on a metal sheet to form a coating; coating on the coating Lithium metal, making lithium battery negative electrode;

[0052] The negative electrode of the lithium battery and the positive electrode LiCoO 2 Set on the left and right sides of the diaphragm, and add 1M LiPF6 EC / DEC solution as the electrolyte, and assemble it into a CR2032 button battery.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap