Cleaning equipment for cattle breeding

A technology for cleaning equipment and cleaning rollers, which can be used in cleaning devices, applications, animal husbandry, etc. It can solve the problems of difficult spraying direction of cleaning water, insufficient practicability, and insufficient gentleness of cattle body, so as to achieve the effect of convenient cleaning work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

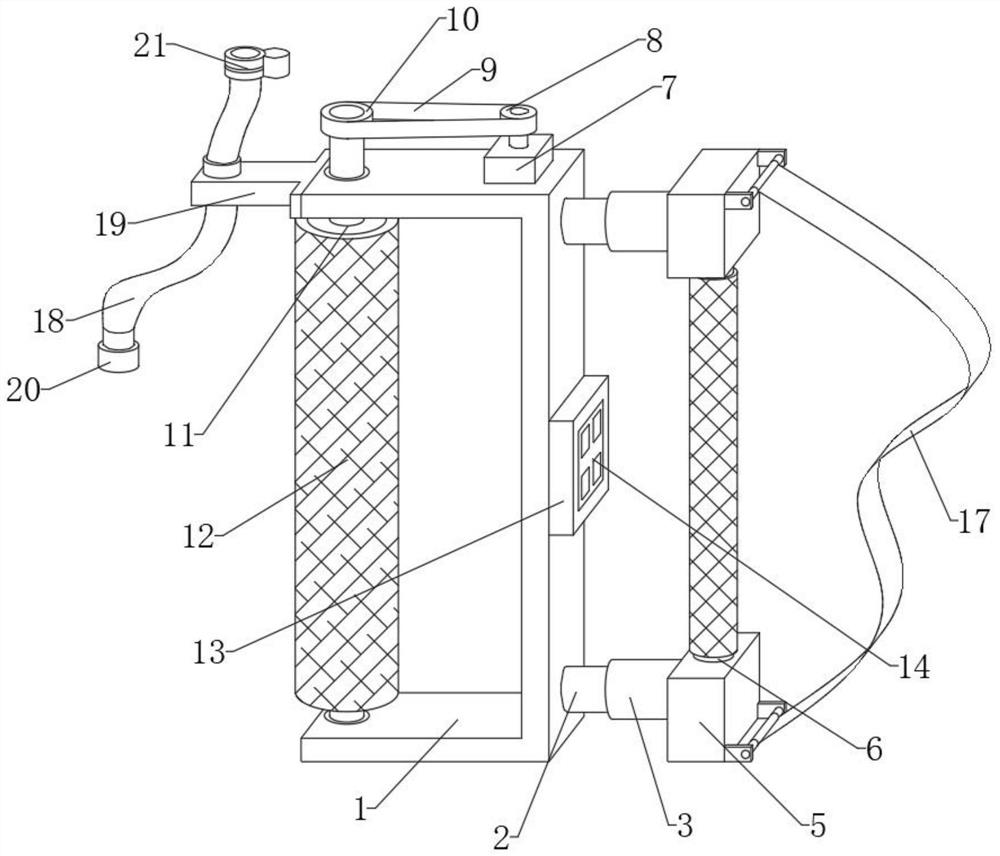

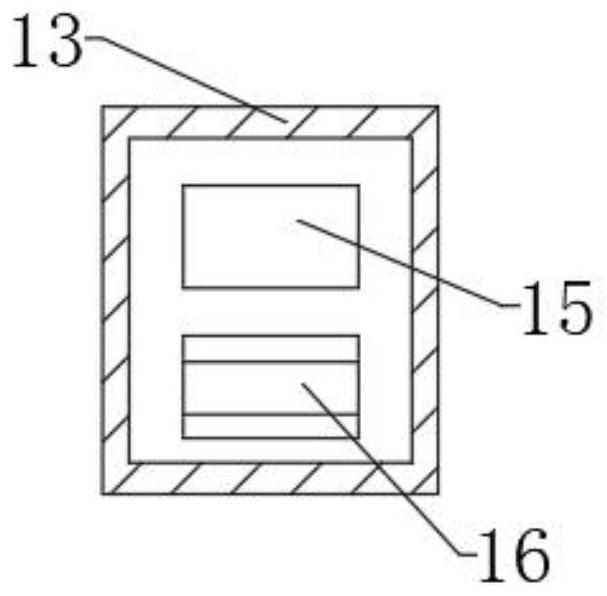

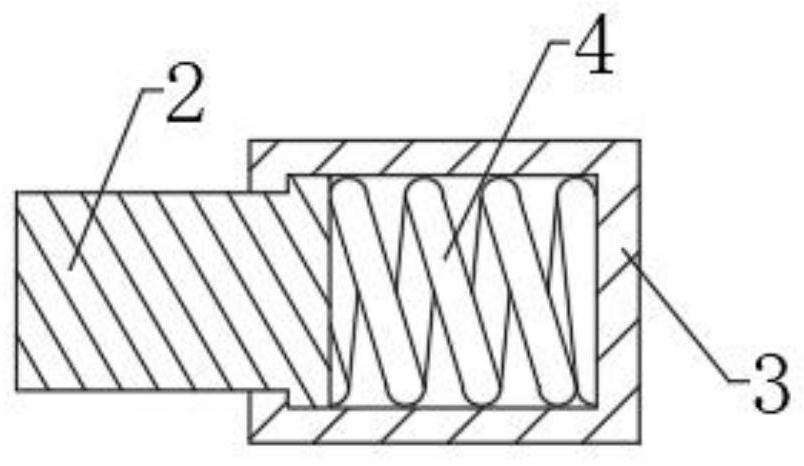

[0024] Such as Figure 1-Figure 4 As shown, a cleaning device for cattle breeding described in this embodiment includes a mounting frame 1, a connecting rod 2 and a handle 6. The connecting rod 2 is welded on both sides of the side wall of the mounting frame 1, and the connecting rod 2 is far away from the mounting frame 1. A sleeve rod 3 is slidingly connected to the outer periphery of one end, and a connecting spring 4 is arranged inside the sleeve rod 3. Connecting block 5, handle 6 is welded between connecting block 5, anti-slip cover is glued on the periphery of handle 6, stepper motor 7 is connected with bolt on one side of the upper end of mounting frame 1, connecting spring 4 can align the connecting rod in sleeve rod 3 2 play the role of shock absorption, that is, the installation frame 1 can play the role of shock absorption, and the staff can hold the handle 6 and the installation frame 1 to use the equipment.

[0025] Such as figure 1 As shown, the output end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com