Preparation method of instant cold noodles

A cold noodle and noodle technology, which is applied in the fields of food science, food preservation, and food coating, can solve the problems of broken noodles, uneasy long-term preservation of instant noodles, and reduced taste and quality of noodles, and achieves the effect of uniform oil coating.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is further described in detail through specific implementation methods:

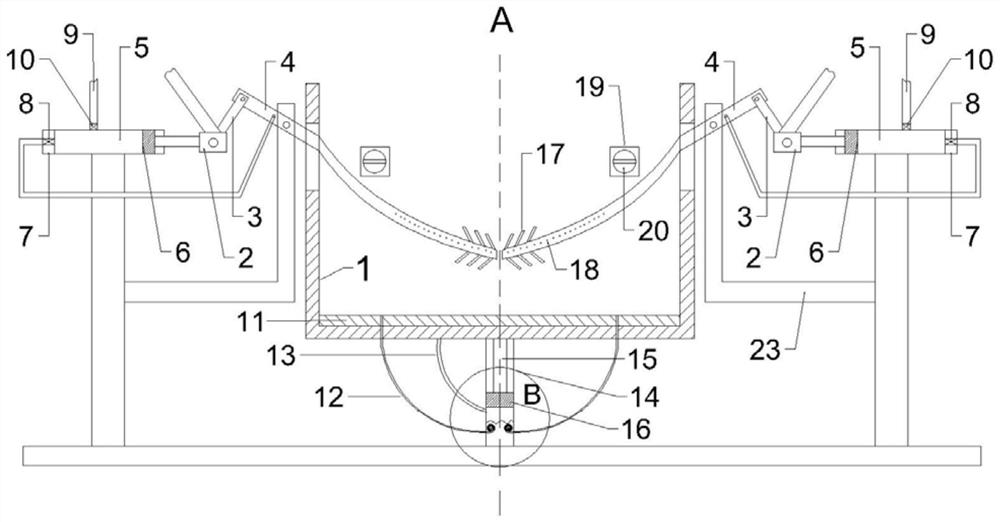

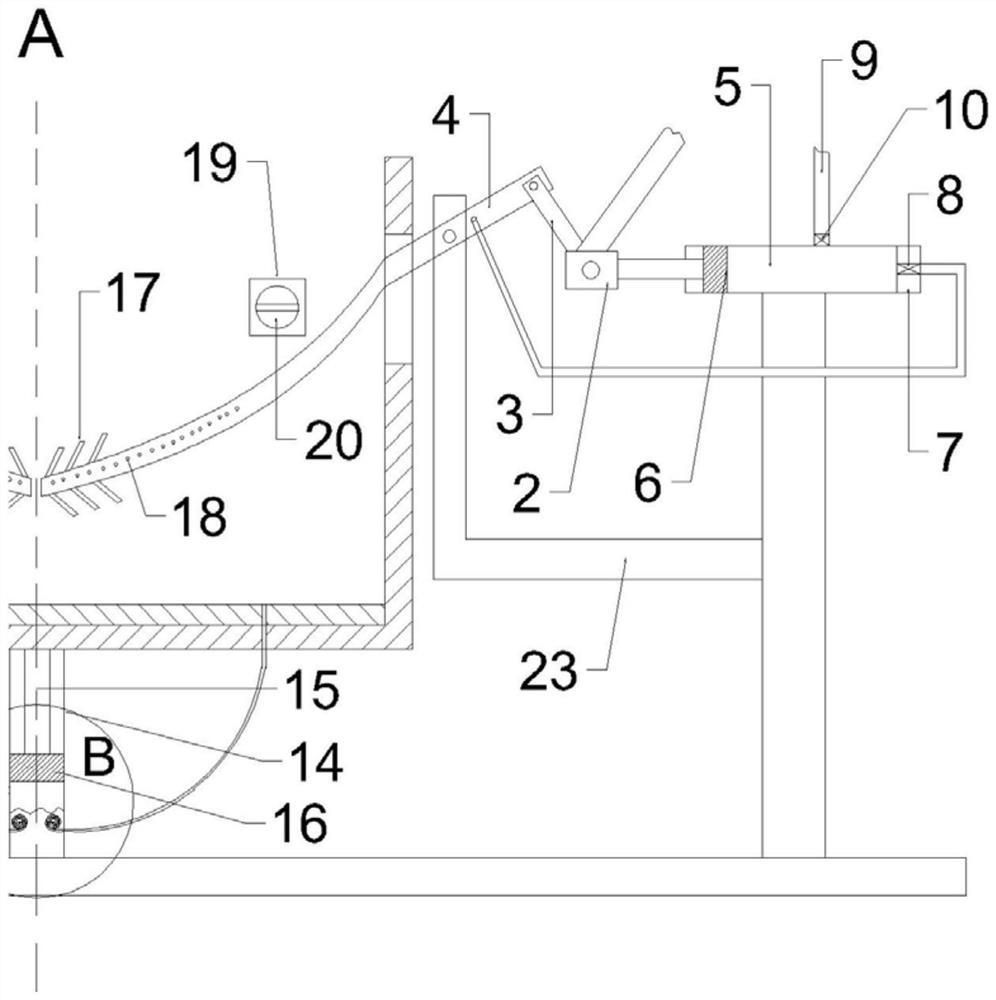

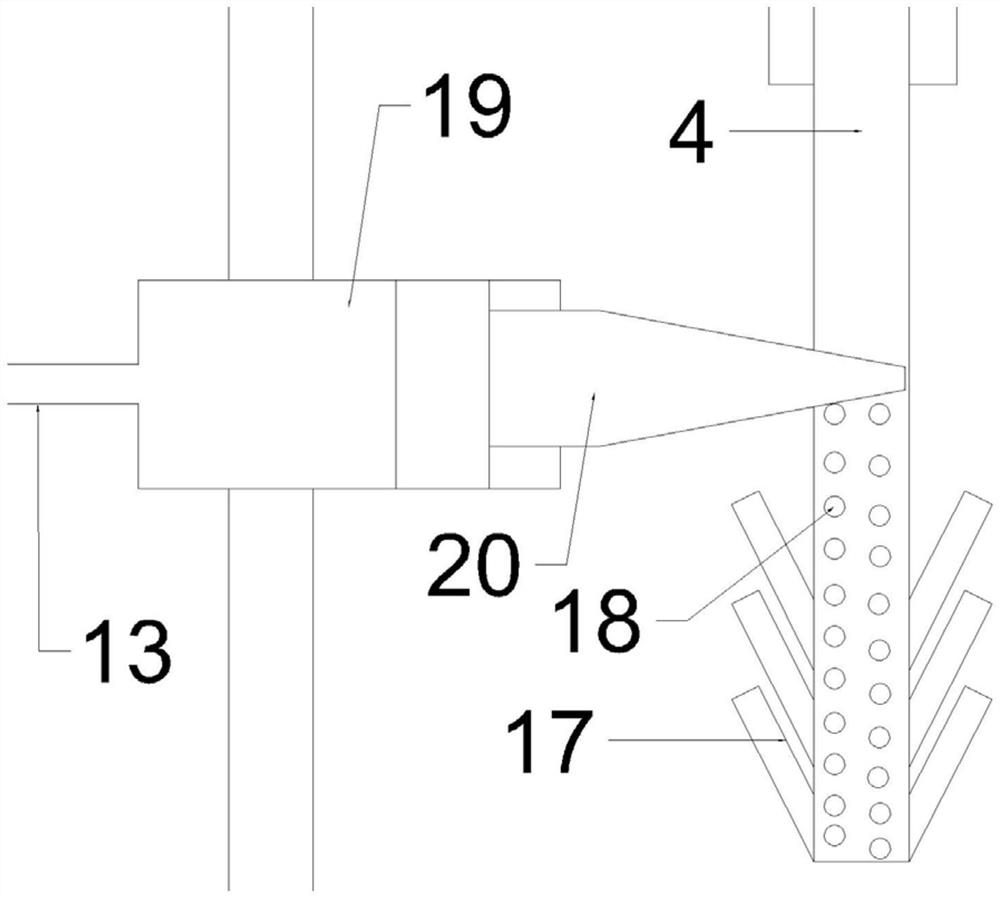

[0034] The reference signs in the drawings of the specification include: 1 stirring tank, 2 slider, 3 first connecting rod, 4 second connecting rod, 5 oil chamber, 6 first plunger, 7 blocking block, 8 first one-way valve , 9 oil inlet pipe, 10 second one-way valve, 11 metal pad, 12 heat conduction rod, 13 air pipe, 14 outer shaft, 15 lifting rod, 16 second plunger, 17 stirring rod, 18 oil hole, 19 telescopic cavity, 20 Baffle bar, 21 expansion cavity, 22 liquid solution, 23 support.

[0035] A method for preparing instant noodles, comprising the steps of:

[0036] Step (1): Prepare 100kg of uncooked fresh noodles made of wheat flour as the main ingredient, mixed with eggs, alkaline water, and miscellaneous grain flour, and spread the noodles at room temperature for 10 minutes;

[0037] Step (2): Blanch the noodles obtained in step (1) in hot water at 95°C for 60 seconds, then put t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com