Oily solid cosmetic

A technology of cosmetics and solids, applied in the direction of cosmetics, cosmetics, cosmetic preparations, etc., can solve the problems that it is difficult to obtain a soft feeling of use, gloss, moist feeling, etc., and achieve excellent exudation stability, easy to smudge, easy to spread effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

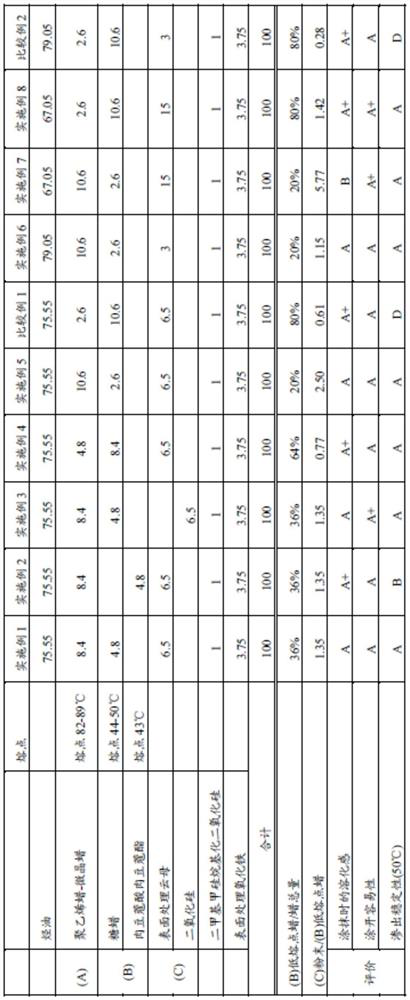

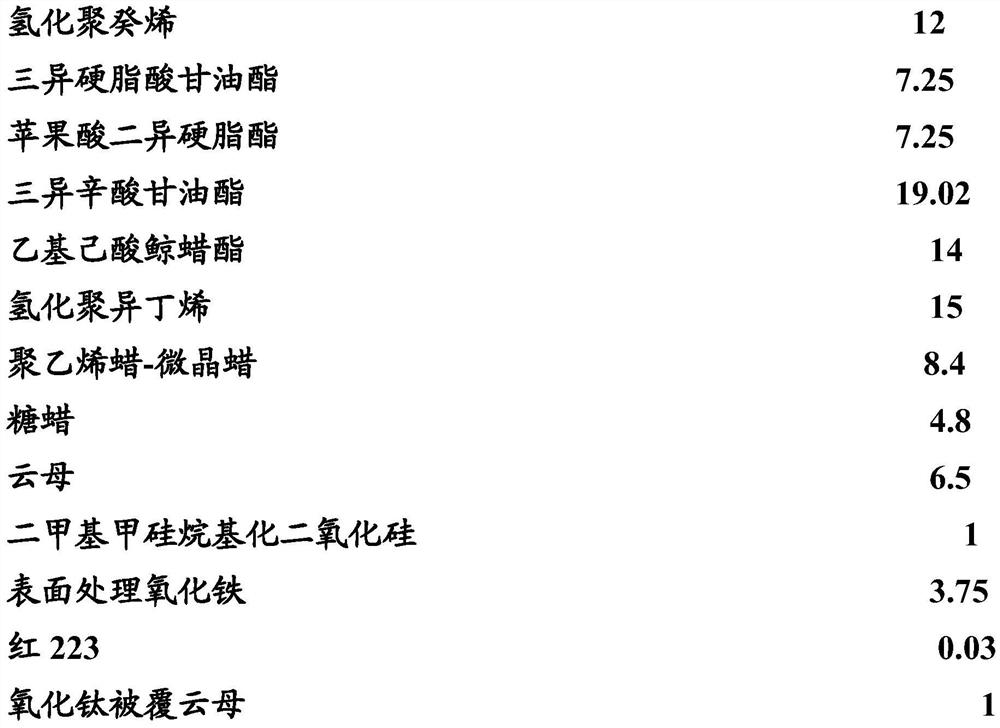

[0066] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples. In addition, unless otherwise specified, the compounding quantity in a following example etc. shows mass %.

[0067] Oil-based solid cosmetics were prepared by conventional methods according to the recipes described in Table 1 below, and evaluated according to the following criteria.

[0068] (melting sensation when applied)

[0069] Using the prepared oil-based solid cosmetics, 10 professionals evaluated the melting sensation when applied. The evaluation criteria are as follows.

[0070]

[0071] 5 points: very good

[0072] 4 points: good

[0073] 3 points: ordinary

[0074] 2 points: Bad

[0075] 1 point: very bad

[0076]

[0077] A+: average score of 4.5 or more

[0078] A: The average score is above 3.5 and less than 4.5

[0079] B: The average score is above 2.5 and less than 3.5

[0080] C: The average score is less than 2.5 poin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com