Disassembling and assembling method for rounding machining assembly

A disassembly method and component technology, which is applied in metal processing equipment, feeding devices, positioning devices, etc., can solve the problems of inconvenient disassembly and replacement of round processing components, and achieve convenient and fast disassembly and replacement, quality assurance, and convenient and fast installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

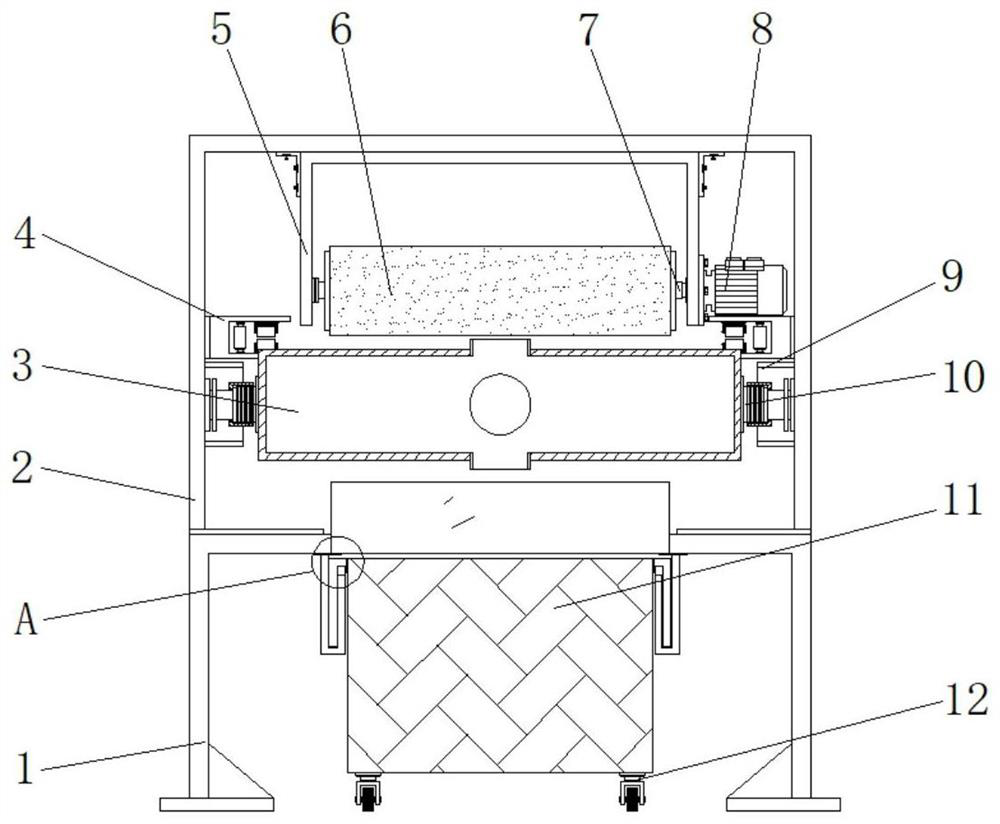

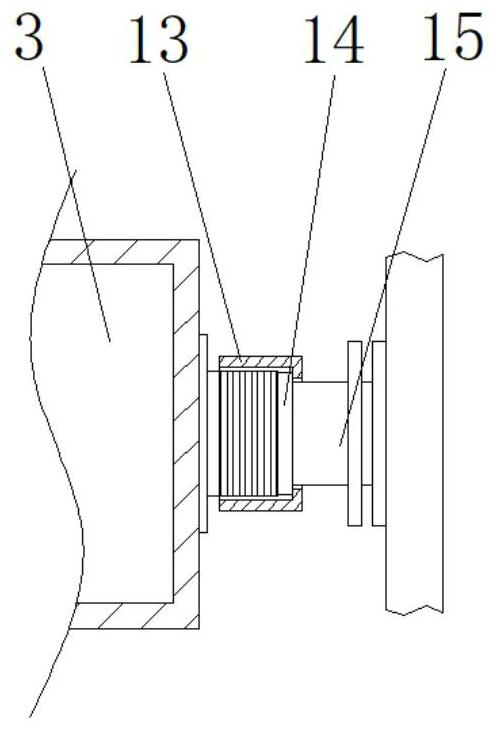

[0020] Example 1: See Figure 1-4 , a method for disassembling and assembling a circle processing assembly, comprising a support frame 1, a frame body 2 is fixedly connected to the top of the support frame 1, and a cylinder 3 is arranged at the bottom of the front end between the two sides inside the frame body 2, and the frame body 2 The middle position of the rear end between the two sides of the interior is fixedly connected with the fixing groove 4, the bottom of the front end between the two sides of the frame body 2 is fixedly connected with the sleeve 9, and the front end at the middle position of the bottom of the support frame 1 is provided with a collecting tank 11. The middle positions on both sides of the forming cylinder 3 are respectively fixedly connected with the connecting block 10, the front end at the middle position of the inner top of the frame body 2 is fixedly connected with the tank body 5, and the bottom end of one side of the tank body 5 is fixedly con...

Embodiment 2

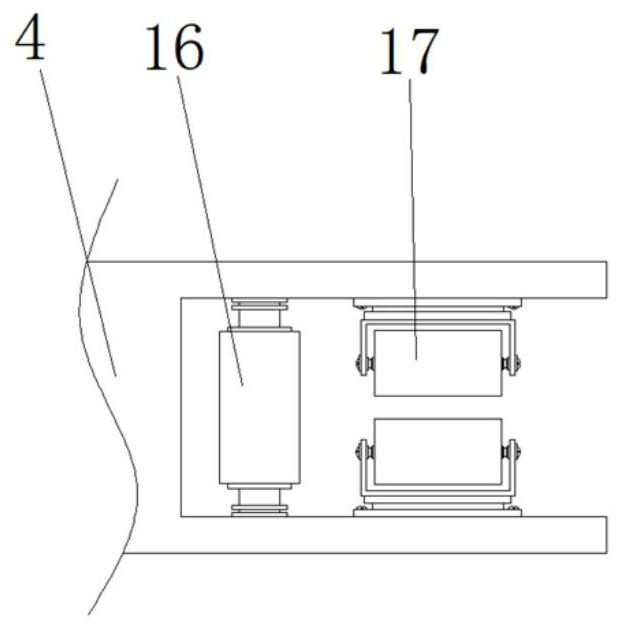

[0023] Embodiment 2: The fixed side between the two ends inside the fixed groove 4 is respectively movably connected with a limiting column 16, and one side of the two ends inside the fixed groove 4 is respectively fixedly connected with a stable guide wheel 17;

[0024] Specifically, such as figure 1 and image 3 As shown, in use, the tinplate in the process of being transferred into a circle is limited by the limiting column 16 that is movably connected between the two ends of the fixed groove 4, and is fixedly connected to the stable ends of the fixed groove 4 on one side. The guide wheel 17 conveys and guides the tinplate, thereby achieving the purpose of stabilizing the tinplate in the rounding process, thereby ensuring the quality of the tinplate in the rounding process.

Embodiment 3

[0025] Embodiment 3: The middle position of the front end of the support frame 1 is fixedly connected with a material guide plate 20, the four corners of the bottom end of the collection tank 11 are respectively fixedly connected with moving wheels 12, and the front ends on both sides of the inner top of the support frame 1 are respectively fixedly connected with Stable slots 19, the tops on both sides of the collection tank 11 are respectively fixedly connected with installation boards 18, the installation boards 18 are respectively in the shape of "L", and the installation boards 18 are respectively inserted in the inside of the stable slots 19;

[0026] Specifically, such as figure 1 and Figure 4 As shown, when in use, the mounting plate 18 fixedly connected to the top of both sides of the collecting tank 11 is plugged into the inside of the stabilizing slot 19 fixedly connected to the front ends of both sides of the inner top of the support frame 1, thereby achieving the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com