High-precision hole machining tool

A hole processing, high-precision technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of danger of workers, flying out of the drill, and vibration of the drill, and achieve the effect of improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

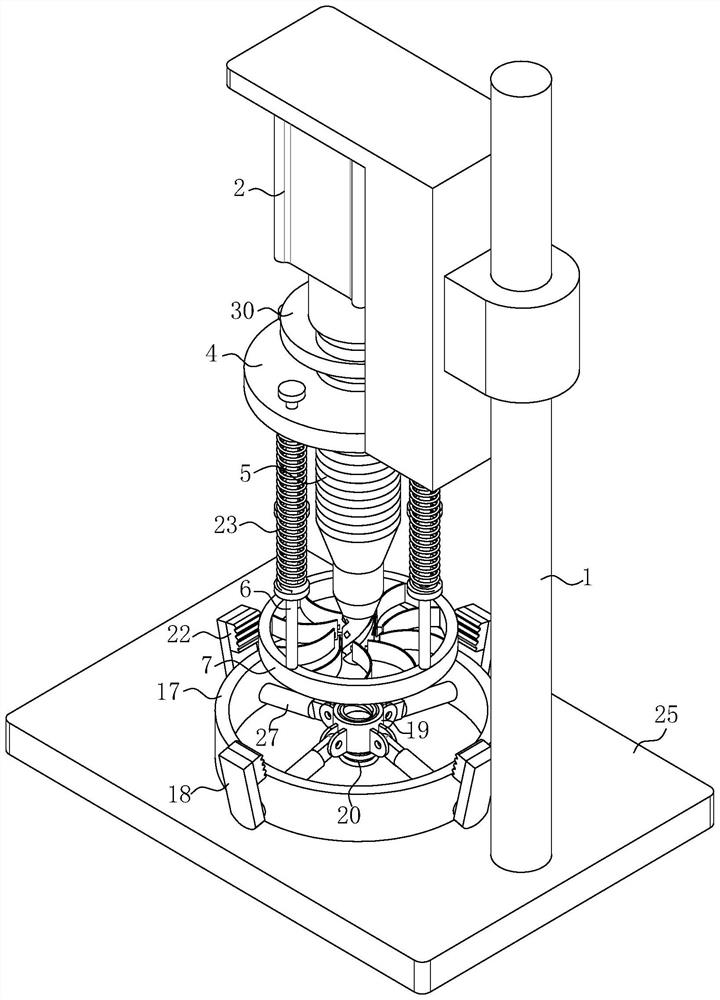

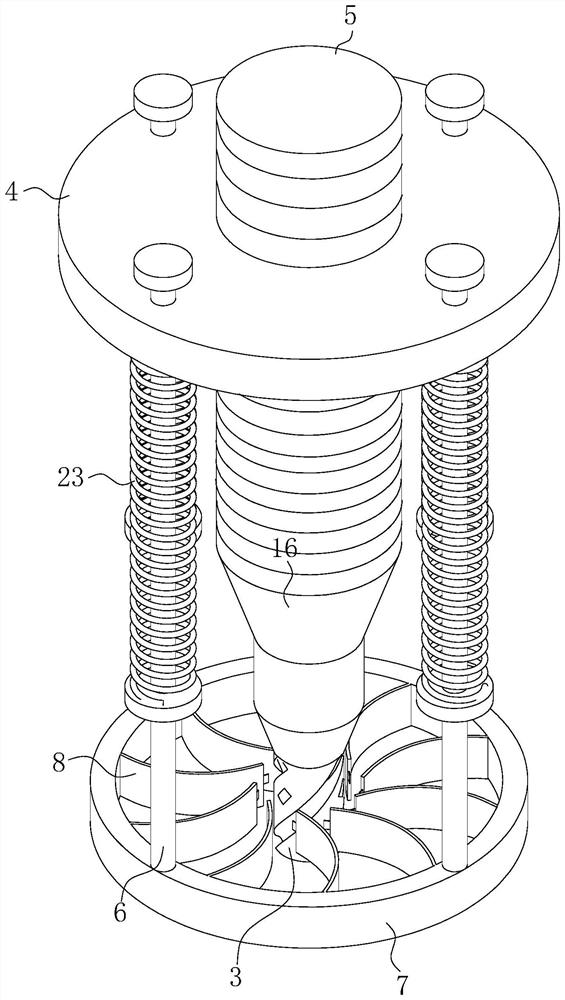

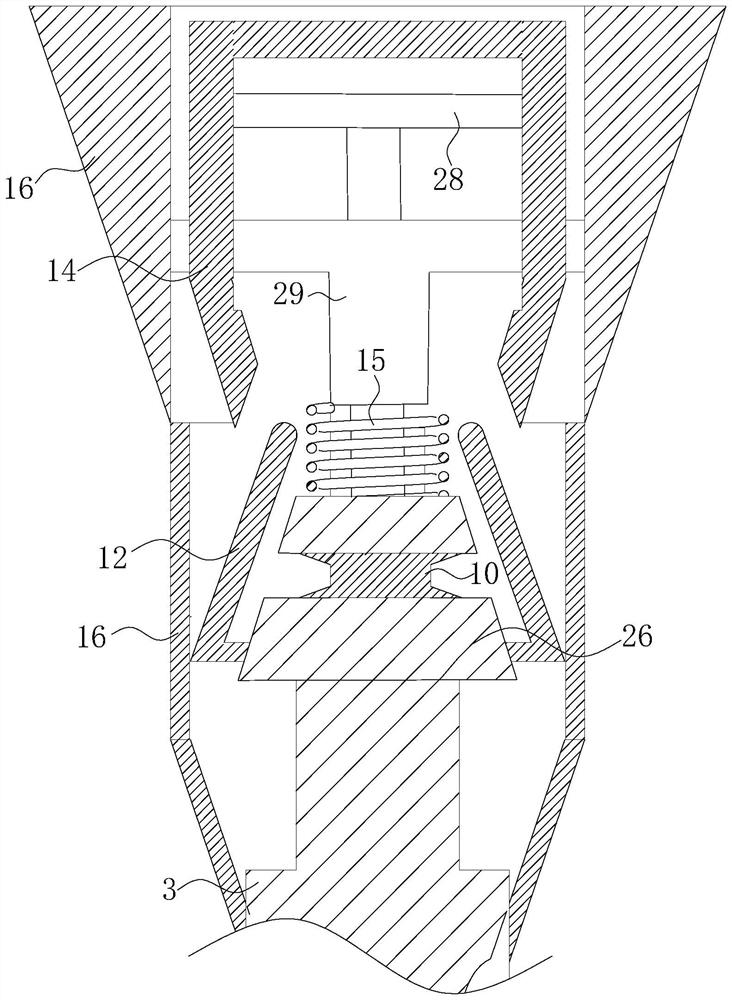

[0027] see Figure 1-10 , the present invention provides a technical solution: one is characterized in that: the support 1 is provided with a cylinder 2, a drill 3 is provided below the cylinder 2, a protective assembly is provided on the drill 3, and the protection The component is used to suppress the vibration of the drill bit when it penetrates the workpiece, and prevent the drill bit from being damaged due to violent vibration, so as to protect the drill bit and the staff. A clamping component is arranged under the protective component, and the clamping component It is used to fix the workpiece during the drilling process, prevent the workpiece from flying out with the rotation of the drill during the drilling process, and ensure the smooth progress of the drilling. The clamping assembly is also used for drilling through the drill Limit the position of the drill after the workpiece to prevent the vibration of the drill after the drilling is completed, and avoid the proble...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com