Lateral horizontal tool magazine adjusting and positioning system of horizontal machining center machine tool

A machining center and positioning system technology, applied to metal processing machinery parts, positioning devices, metal processing equipment, etc., can solve the problems of insufficient precision and efficiency, and achieve the effects of improving practicability, avoiding tilt, and improving accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

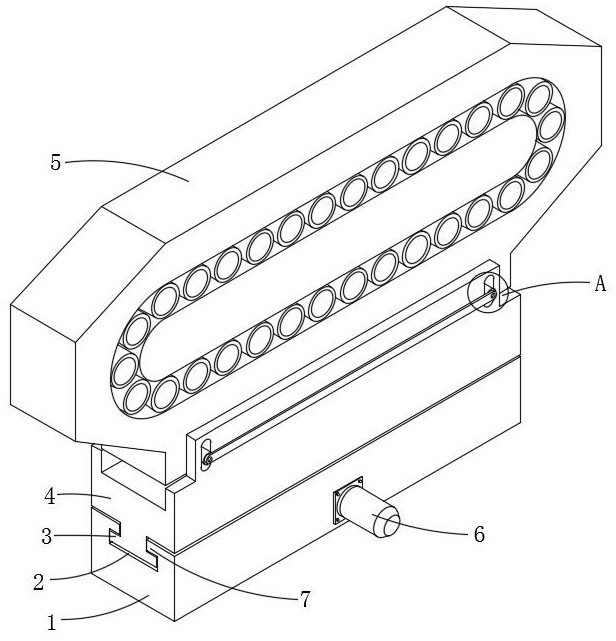

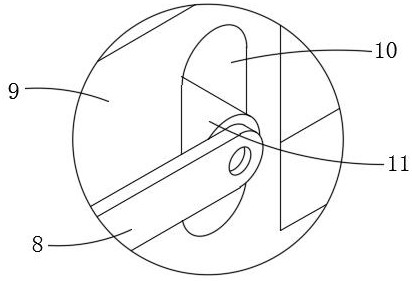

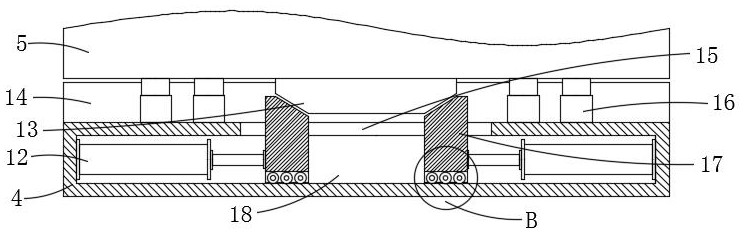

[0033] see Figure 1 to Figure 6 , the present invention provides a side-mounted horizontal tool magazine adjustment and positioning system for a horizontal machining center machine tool, comprising: an X-axis adjustment seat 1; a height adjustment seat 4, the height adjustment seat 4 is arranged on the top of the X-axis adjustment seat 1, and the height adjustment The top of the seat 4 is provided with a first accommodating groove 14, the interior is provided with a cavity 18, and the bottom is provided with a groove 15; Snapped inside the first accommodation groove 14, the bottom of the tool magazine body 5 is integrally formed with a fixed seat 13; the height adjustment mechanism is located between the tool magazine body 5 and the height adjustment seat 4; the X-axis adjustment mechanism, The X-axis adjustment mechanism is located between the height adjustment seat 4 and the X-axis adjustment seat 1; wherein, the cavity 18 communicates with the outside world through the gro...

no. 2 example

[0038] In a specific embodiment, the X-axis adjustment mechanism includes: an adjustment chute 2, the adjustment chute 2 is arranged on the top of the X-axis adjustment seat 1; a connection part 28, and the connection part 28 is arranged on the bottom of the height adjustment seat 4; Plate 3, the adjustment plate 3 is located at the bottom of the connecting part 28, the bottom of the adjustment plate 3 is provided with locking teeth; the drive motor 6, the drive motor 6 is fixedly installed on the surface of the X-axis adjustment seat 1; the adjustment gear 29, the adjustment gear 29 and The output end of the drive motor 6 is connected, and the adjustment gear 29 runs through the surface of the adjustment chute 2 and meshes with the locking teeth at the bottom of the adjustment plate 3 .

[0039] The top of the X-axis adjustment seat 1 is provided with an adjustment chute 2, the bottom of the height adjustment seat 4 is integrally formed with a connecting portion 28, and the bo...

no. 3 example

[0043] In a specific embodiment, the buffer assembly includes: a buffer seat 16, which is fixedly installed on the bottom of the first receiving groove 14; a buffer post 23, which is inserted into the interior of the buffer seat 16; a buffer spring 27, Both ends of the buffer spring 27 are respectively fixed to the bottom of the inner chamber of the buffer column 23 and the bottom of the buffer seat 16 .

[0044] The buffer assembly includes a buffer seat 16, a buffer column 23 and a buffer spring 27. The buffer seat 16 is fixedly installed on the bottom of the first receiving tank 14. There are usually four buffer seats 16, and the buffer seat 16 is fixedly connected to the bottom of the first receiving tank 14. , and the four buffer seats 16 are arranged symmetrically with respect to the center of the tool magazine body 5, when the tool magazine body 5 descends, the left and right sides will be buffered by the two buffer seats 16, and the buffer column 23 is inserted into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com