Environment-friendly degradable bamboo straw processing device

A processing device, bamboo technology, applied in the direction of sugarcane machining, grinding drive device, metal processing equipment, etc., can solve the problems of increasing the processing time of bamboo tubes, reducing the processing efficiency of bamboo tubes, and easy cracking of bamboo tubes, so as to avoid The cracking of the bamboo tube facilitates the subsequent collection and reduces the effect of processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

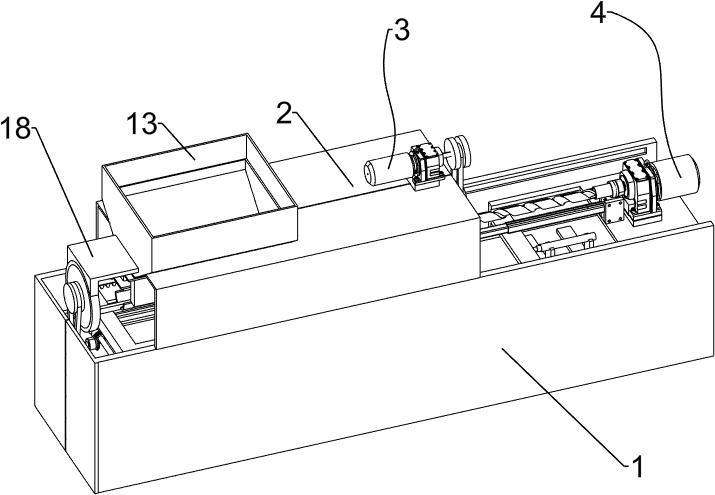

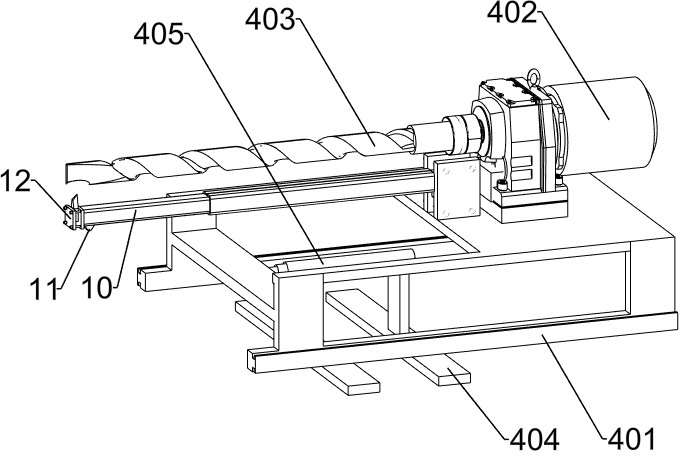

[0030] An environmentally friendly and degradable bamboo straw processing device, such as figure 1 As shown, it includes an installation frame 1, a protective frame 2, a bamboo tube limit grinding assembly 3 and a bamboo tube drilling assembly 4. The top of the installation frame 1 is provided with a protective frame 2, and the protective frame 2 is provided with a bamboo tube limit grinding assembly. Component 3, the inner right part of the installation frame 1 is provided with a bamboo tube drilling component 4.

[0031]During use, the user puts the bamboo tube into the bamboo tube limit grinding assembly 3, and the bamboo tube limit grinding assembly 3 works, and the bamboo tube limit grinding assembly 3 works to polish the outer surface of the bamboo tube, and simultaneously Carry out the limit, then the user starts the bamboo tube drilling assembly 4 to work, the bamboo tube drilling assembly 4 works to punch holes at the bamboo joints of the bamboo tube, when the bamboo ...

Embodiment 2

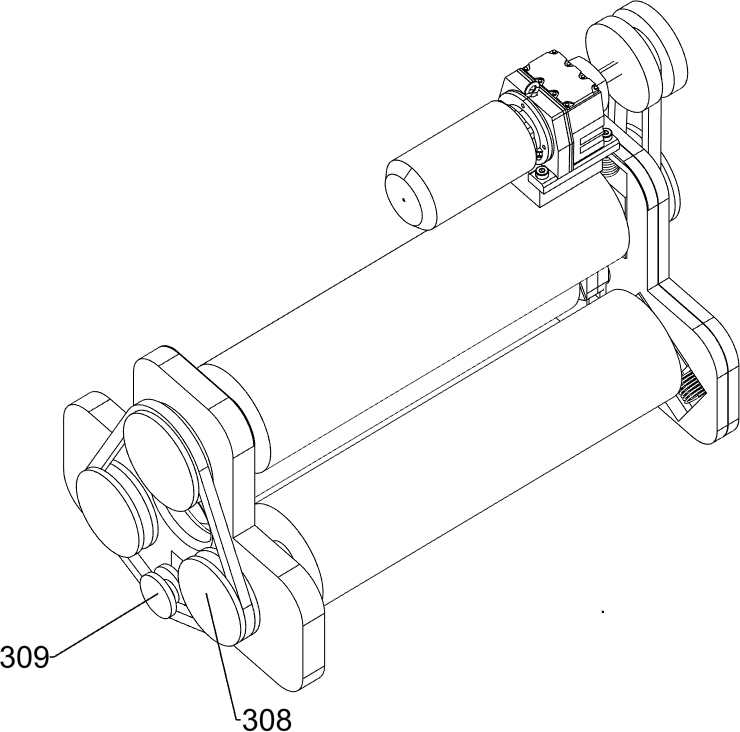

[0033] On the basis of Example 1, such as Figure 1-Figure 12 As shown, the bamboo tube limit grinding assembly 3 includes a mounting plate 301, a slide block 303, a support spring 304, a friction roller 305, a first pulley 306, a reduction motor 307, a second pulley 308 and a tension pulley 309, and the protection The middle part and the right part of the inner upper surface of the frame 2 are fixedly connected with a mounting plate 301, the middle part of the left mounting plate 301 is provided with a feed inlet, and the middle part of the right mounting plate 301 is provided with a cavity extending downward, and the two mounting plates The inner surface of 301 is provided with three chute 302, the cavity on the right side mounting plate 301 communicates with the two chute 302 on the lower side, slide block 303 is provided in the chute 302, and the slide block 303 and the mounting plate 301 A supporting spring 304 is fixedly connected between them, and a friction roller 305 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com