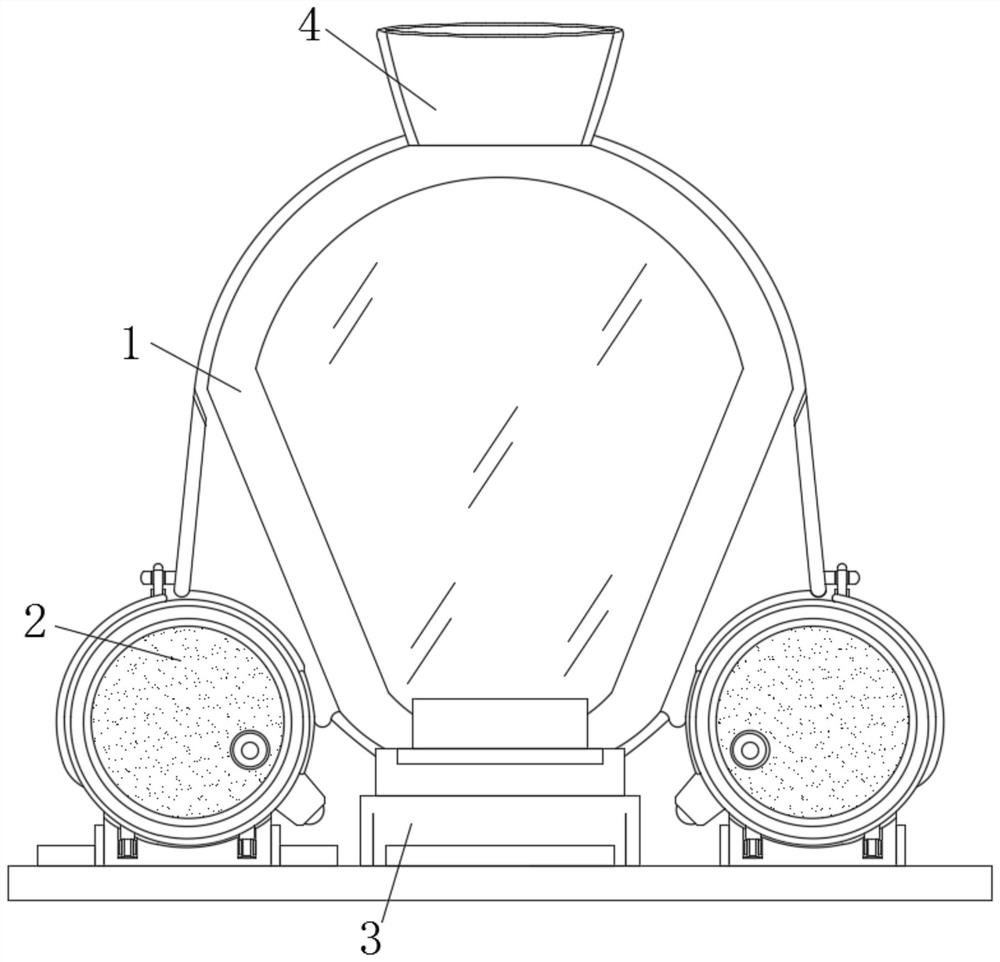

Granule counting machine

A technology of counting machine and body, applied in the field of counting machine, can solve the problems of reducing conveying efficiency and detection accuracy, affecting material conveying efficiency, reducing detection accuracy, etc., to improve automatic classification and detection function, improve conveying efficiency, The effect of enhancing detection accuracy and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

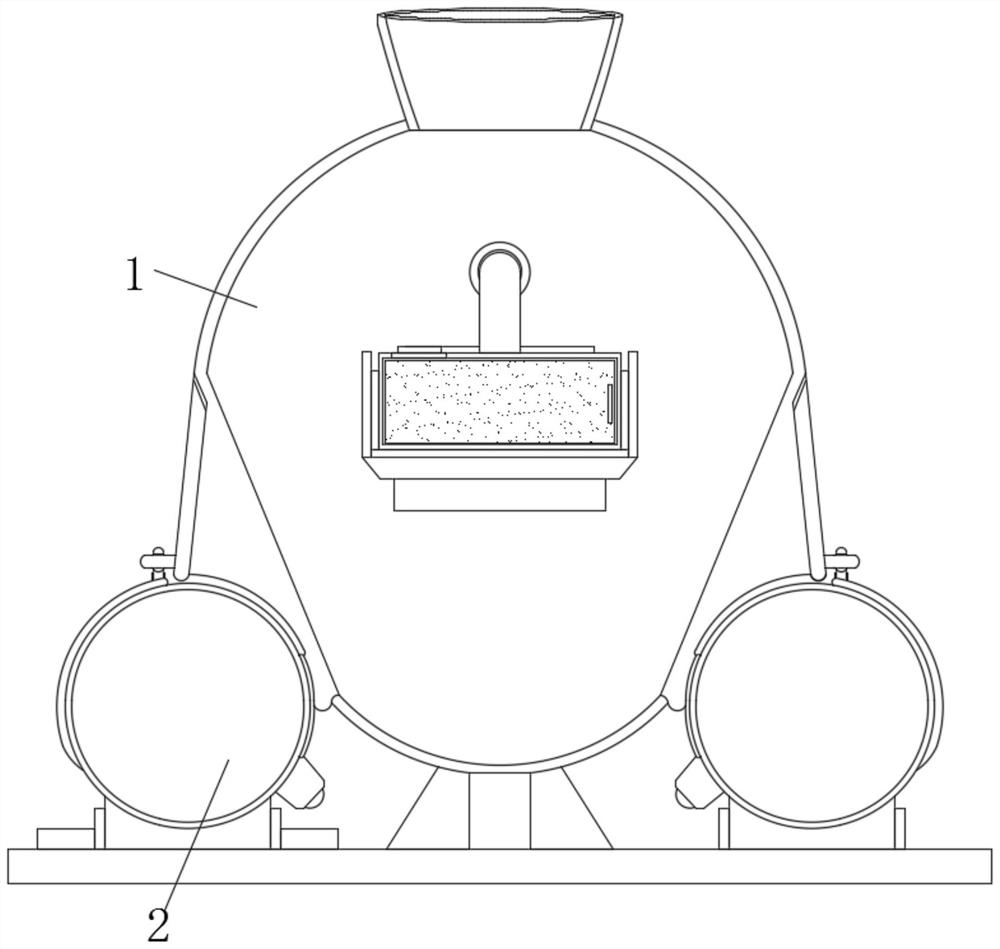

Embodiment 1

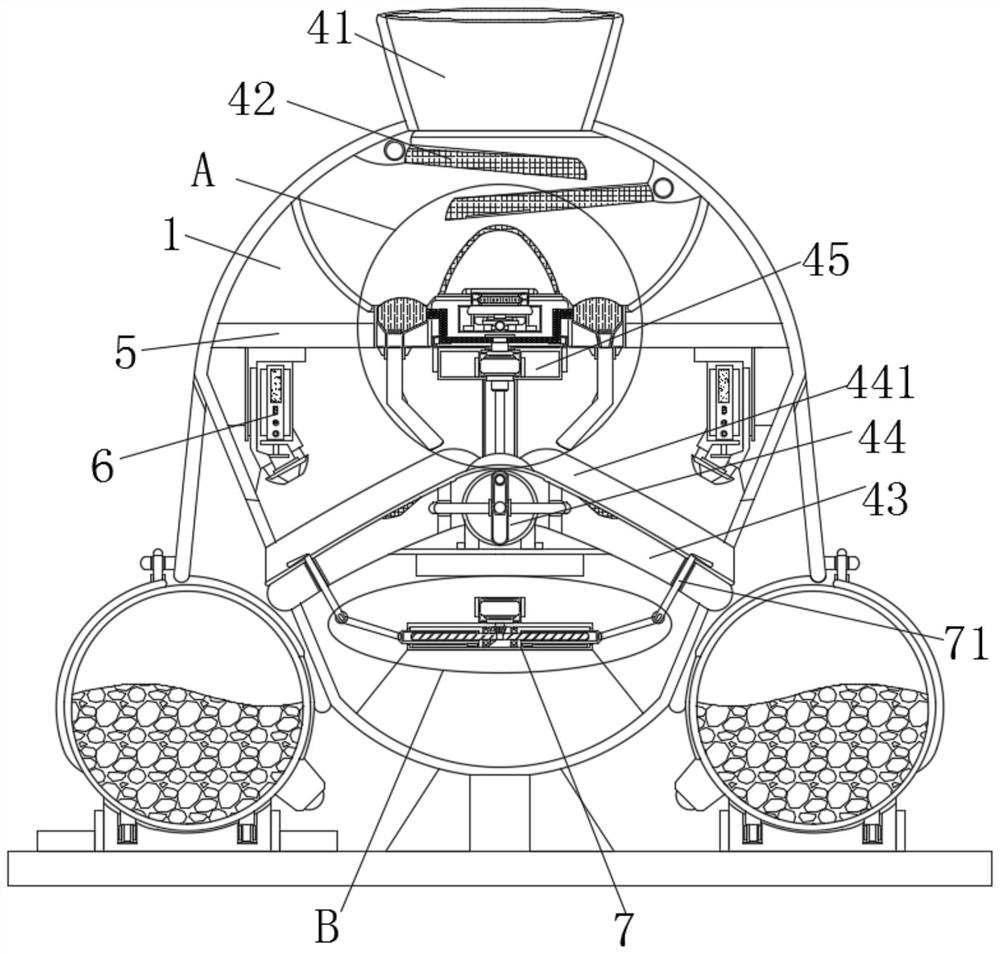

[0044] Example 1, such as Figure 1-3 As shown, while the material is guided through the classification feeding system 45 for secondary guidance, the dust can be prevented from spreading through the annular dust suction chamber outside the annular guide groove 453, and the material can be accurately slid in under the structural guidance of the cavity. The inside of the annular guide groove 453, at this time, the suction fan 457 can be activated to suck the dust into the storage groove completely through the guide tube under the filtration of the conical filter seat 451, which is convenient for the operator to carry out subsequent cleaning operations and avoids material clogging .

Embodiment 2

[0045] Example 2, such as figure 2 and Figure 5 As shown, when the two groups of material receiving seats 2 are full of materials, the start of the servo motor 77 can drive the second bevel gear set 74 to engage in the structure and force the two-way screw rod 73 to rotate, and the rotation of the two-way screw rod 73 will prompt the two groups of materials The threaded pipes 75 move away from each other, so that the internal threaded pipe 75 drives the hinged connecting rod 76 to raise the baffle 71, so that the baffle 71 erects a blocking structure on the conveying edge of the inclined material guide plate 441, and at this time, the particles can be temporarily The material is blocked, and the receiving seat 2 can be replaced during the period, and the monitoring of the infrared spectrum detector 6 is not stopped, so that the device can be replaced without stopping the material receiving seat 2, and the functionality of the device can be increased.

[0046] Working princi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap