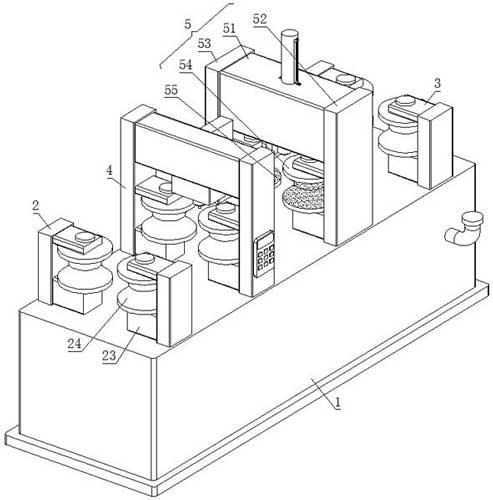

Forming device and method for seam heat treatment of high-frequency straight seam welded steel pipe

A technology for forming devices and welded steel pipes, applied in heat treatment furnaces, heat treatment equipment, furnace types, etc., can solve problems such as increased use costs, inconvenient use, and excess power of motors, so as to increase use costs, reduce use costs, and avoid excess power Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach , Embodiment approach

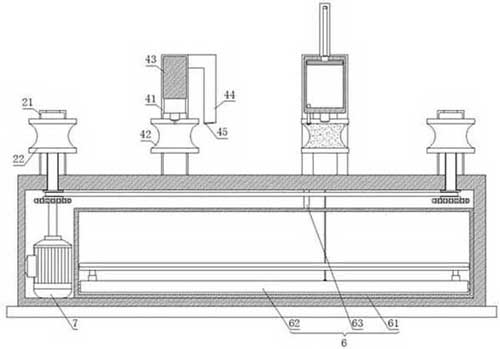

[0058] In order to further explain the above embodiments better, the present invention also provides an embodiment, the implementation method of the forming device for the heat treatment of the weld seam of the high-frequency straight seam welded steel pipe, comprising the following steps:

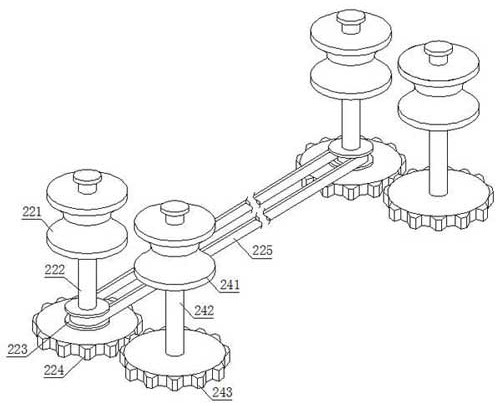

[0059] Step 1: When the operator needs to form the pre-processed steel pipe, one end of the steel pipe can be placed between the first forming roller 22 and the second forming roller 24, and the motor 7 is started at this time, and the output of the motor 7 The end will drive the first forming roller 22 to rotate counterclockwise;

[0060] Step 2: Under the transmission action of the second gear 243 and the first gear 224, the second forming roller 24 can be driven to rotate clockwise, so that one end of the steel pipe can be transported in the direction of the welding scraping assembly 4;

[0061] Step 3: When one end of the steel pipe reaches between the third forming rollers 42, the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com