Automatic wall brick pasting device capable of uniformly smearing cement for building construction

A technology of building construction and cement, which is applied in the field of automatic wall tile installation for building construction, can solve the problems of air and cement thickness difference, and achieve the effects of preventing unevenness, improving efficiency and reducing life span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

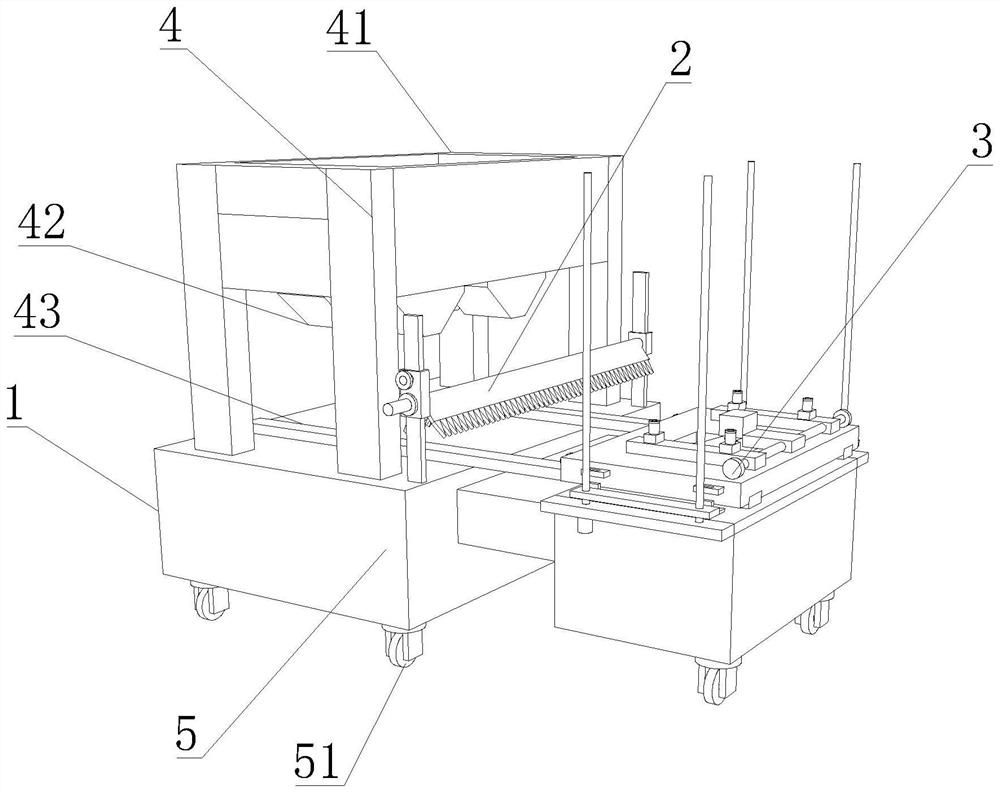

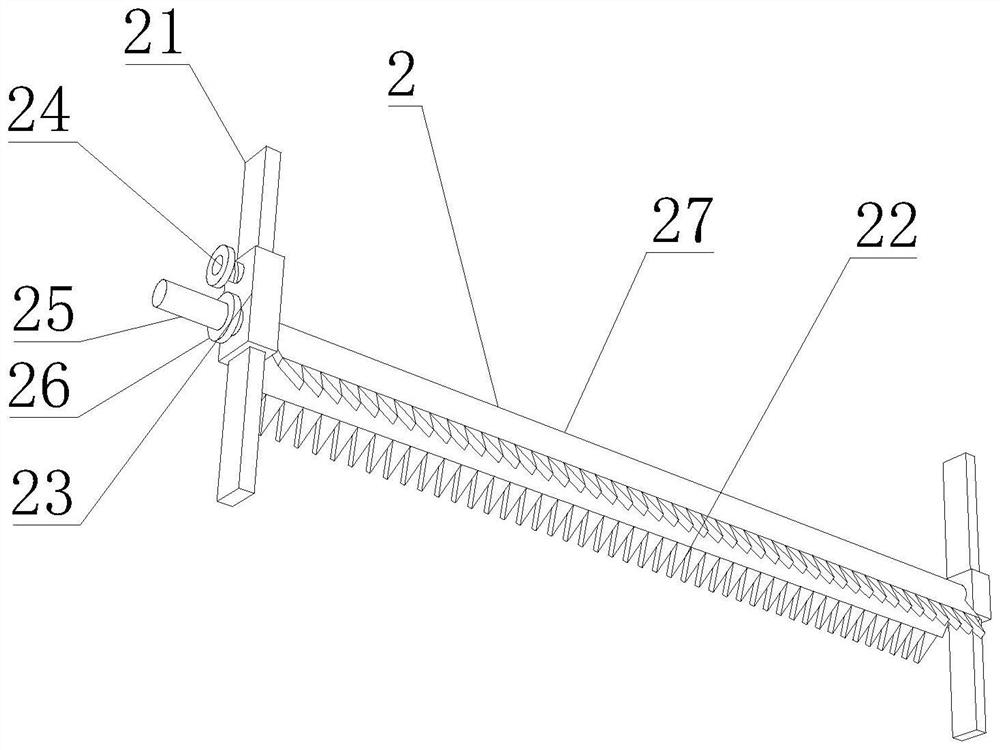

[0032] Such as Figure 1-6As shown, the present invention provides an automatic wall tile installation for building construction that can evenly apply cement. The main body of the tile installation device 1 includes a base 5, and the bottom of the base 5 is movably connected with a runner 51. The top of the base 5 is provided with a mud discharge device 4, and one side of the mud discharge device 4 is provided with a smoothing device 2, and one side of the mud discharge device 2 is provided with a rotating device 3, and the smoothing device 2 includes a fixed rod 21, and the fixed rod The bottom of 21 is fixedly connected with the top of base 5, and the outer wall of fixed rod 21 is movably connected with movable block 23, and one side of movable block 23 is provided with first scraper bar 22 and second scraper bar 27, and rotating device 3 includes fixed seat 31, one side of the fixed seat 31 is fixedly connected with the first motor 32, the output shaft of the first motor 32...

Embodiment 2

[0034] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the outer wall of the threaded rod 33 is movably connected with a threaded sleeve rod 34, and one side of the threaded sleeve rod 34 is provided with a slide bar to fix the buckle The inner wall of 35 is movably connected with the outer wall of threaded sleeve rod 34, and one side of fixed buckle 35 is fixedly connected with one side of movable plate 36, and the outer wall of movable plate 36 is movably connected with the top of fixed seat 31, and the top of movable plate 36 is movable. Connected with rotating rod 37, the outer wall of rotating rod 37 is fixedly connected with vacuum pump 38, and the outer wall of rotating rod 37 is fixedly connected with vibrating device 39, and the bottom of vibrating device 39 is movably connected with electrohydraulic device 381, and the other end of electrohydraulic device 381 and The outer wall of movable pl...

Embodiment 3

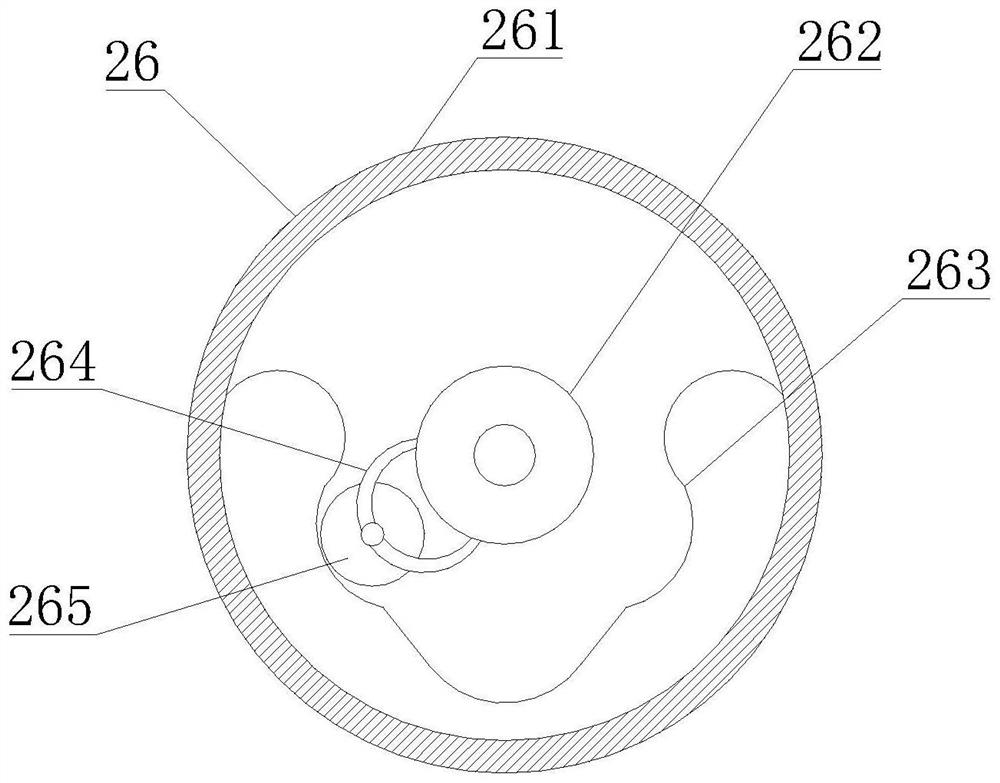

[0036] Such as Figure 1-6 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the vibration device 39 includes a housing 391, the inner wall of the housing 391 is fixedly connected with a third motor 392, and the output shaft of the third motor 392 is fixed Vibrating wheel 393 is connected, the top of shell 391 is movably connected with vibrating column 395, the bottom of vibrating column 395 is fixedly connected with baffle plate 394, the outer wall of baffle plate 394 is movably connected with the outer wall of vibrating wheel 393, and the bottom of vibrating column 395 is fixedly connected There is a moving rod 396, and the outer wall of the moving rod 396 is movably connected with an elastic column 397. Through the rotation of the third motor 392, the vibrating wheel 393 is used to squeeze the baffle plate 394, so that the vibrating column 395 vibrates through the elastic force of the elastic column 397, Vibrate and fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com