Platinum heating system in glass manufacture

A heating system and glass manufacturing technology, applied in the direction of non-metallic elements, inorganic chemistry, halogen/halogen acid, etc., can solve the problems such as the inconvenient control of the height of the gate brick, the short service life of the homogenizing cylinder, and the reduction of glass quality, so as to avoid Effects of heat loss, avoiding contamination, and uniform glass temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

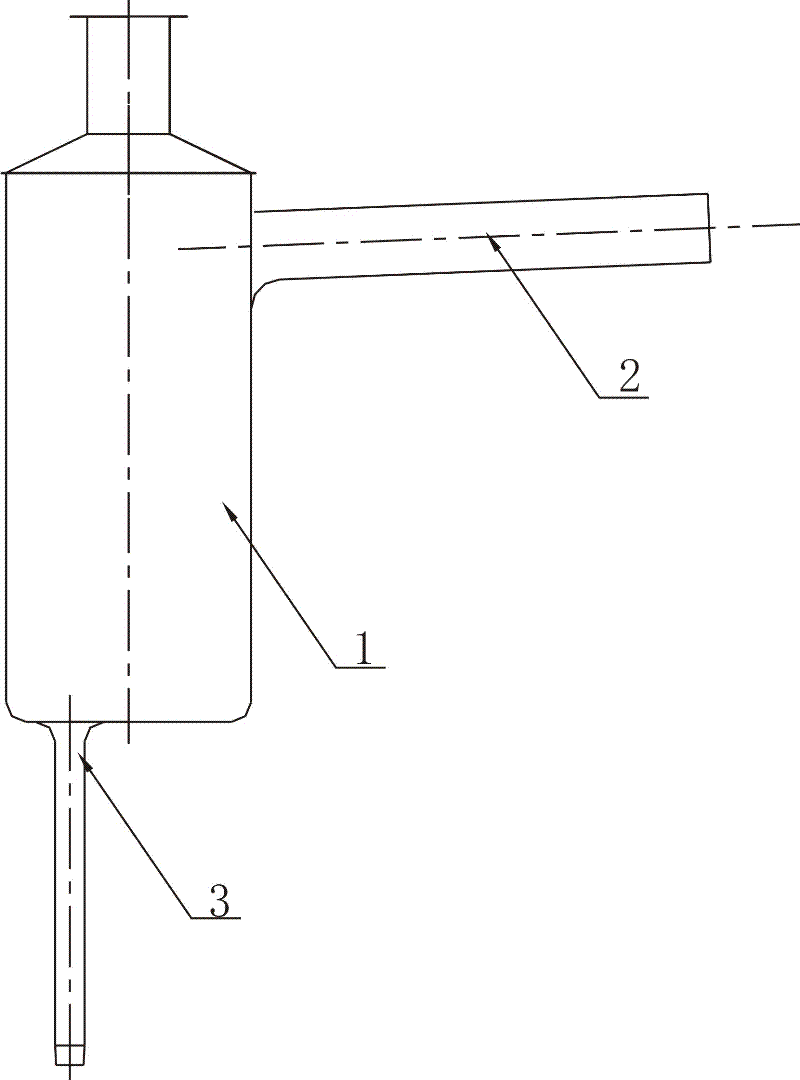

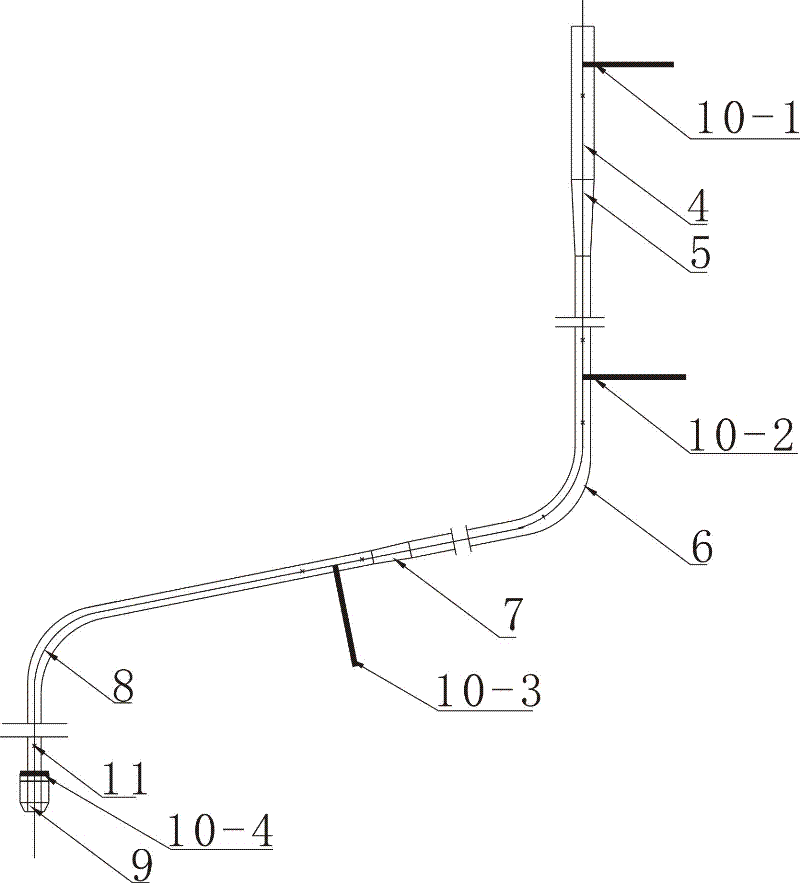

[0021] A platinum heating system in glass manufacturing, comprising a working pool 1, the upper end of the working pool 1 is connected to a connecting pipe 2, and the lower end is provided with a discharge port 3, the discharge port 3 is connected to a discharge pipe 4, and the discharge pipe 4 is connected to a second A tapered pipe 5, the first tapered pipe 5 is connected to the first pipe 6, the first pipe 6 is connected to the second tapered pipe 7, the second tapered pipe 7 is connected to the second pipe 8, the outlet of the second pipe 8 is provided with an electrode sleeve 9, and the electrode A fourth electrode plate 10-4 is connected to the sleeve 9.

[0022] The discharge pipe 4 is provided with a first electrode plate 10-1, the first pipeline 6 is provided with a second electrode plate 10-2, and the second pipeline 8 is provided with a third electrode plate 10-3.

[0023] A thermocouple 11 is provided on the discharge pipe 4 , the first pipeline 6 and the second pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com