Fabricated subway station and construction method thereof

A subway station, prefabricated technology, applied in underground chambers, shaft equipment, earthwork drilling, etc., can solve the problems of long subway construction period, reduce backfill, improve the quality of the operating environment, and improve the utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

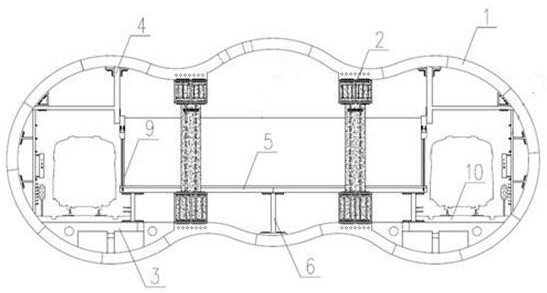

[0062] Embodiment 2, the difference from Embodiment 1 is that the prefabricated track foundation 3, the prefabricated platform slab 5, the lower wall of the platform slab 6, the prefabricated rail top air duct 4 and the segment connection support system are all connected by bolts, Further improve the quality of the working environment and reduce the construction period. And the bolt connection is not only convenient for installation, but also convenient for disassembly and replacement. The prefabricated platform slab 5 and the prefabricated rail top air duct 4 can adopt either steel structure or prefabricated concrete structure. Holes can be opened above the prefabricated platform slab 5 and the prefabricated rail top air duct 4 to facilitate the insertion or ventilation of pipelines.

Embodiment 3

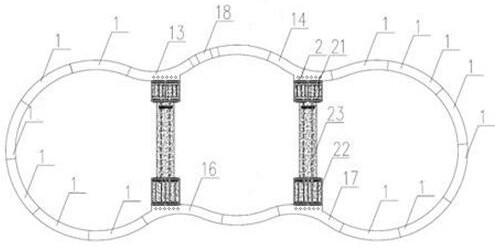

[0063] Embodiment 3, its difference with embodiment 1 is, as Figure 13 As shown, the one-piece structural beam member includes " "Type component 24, the longitudinal section of this component perpendicular to the direction of tunnel excavation is " "Type. Specifically, the upper end of the column passes through the installation and disassembly section 7 and " "Type member 24 is connected. The lower end of the column is connected with " "Type component bolt connection; the two ends of the installation and disassembly section 7 are connected with the column and the " "Type members 24 are all bolted.

[0064] A kind of construction method of described prefabricated subway station, comprises the steps:

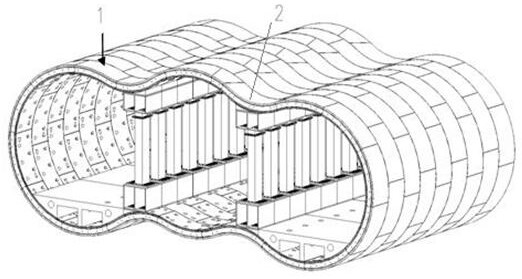

[0065] S1. Use the triple-circle roadheader to excavate, assemble the triple-circle subway station segments while excavating, and assemble the segment connection support system, wherein the segments are assembled piece by piece from bottom to top when assembling, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com