Rapid adjusting and leveling device for flatness measurement and leveling method

A flatness and fast technology, applied in the direction of mechanical roughness/irregularity measurement, to achieve the effect of convenient adjustment, improved adjustment efficiency and overall measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

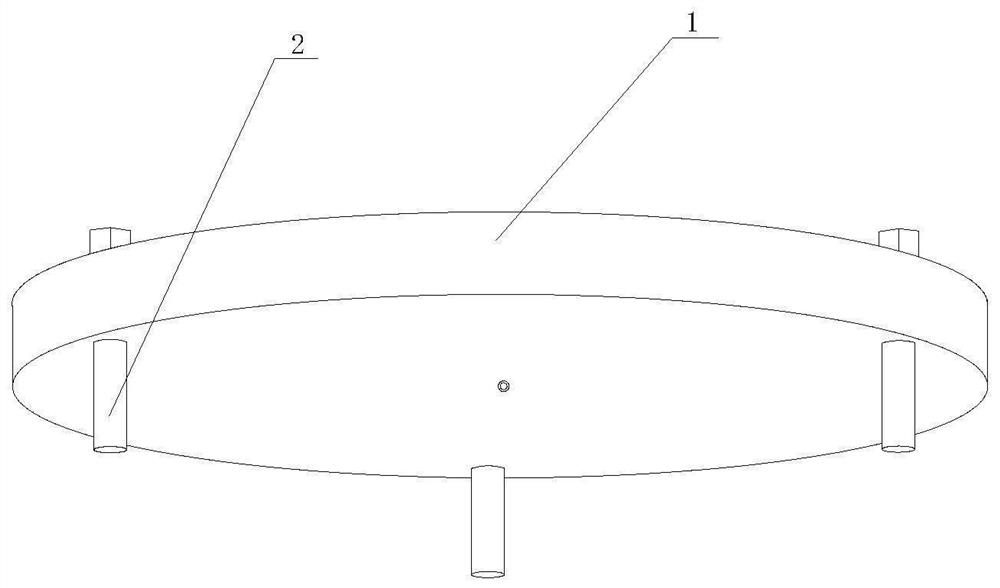

[0028] see figure 1 and figure 2 The quick adjustment leveling device for flatness measurement provided in this embodiment includes a support body 1 and screws 2; there are three screws 2, and the three screws 2 are evenly distributed on the support body 1 along the same circumference; the three screws 2 are respectively Through the support body 1; the head ends of the three screws 2 are placed on the upper plane side of the support body 1.

[0029] In this embodiment, the support body 1 is a cylindrical structure, and the top end surface of the screw rod of the screw 2 is an arc-shaped surface; the radius of the arc is equal to the height of the screw 2 .

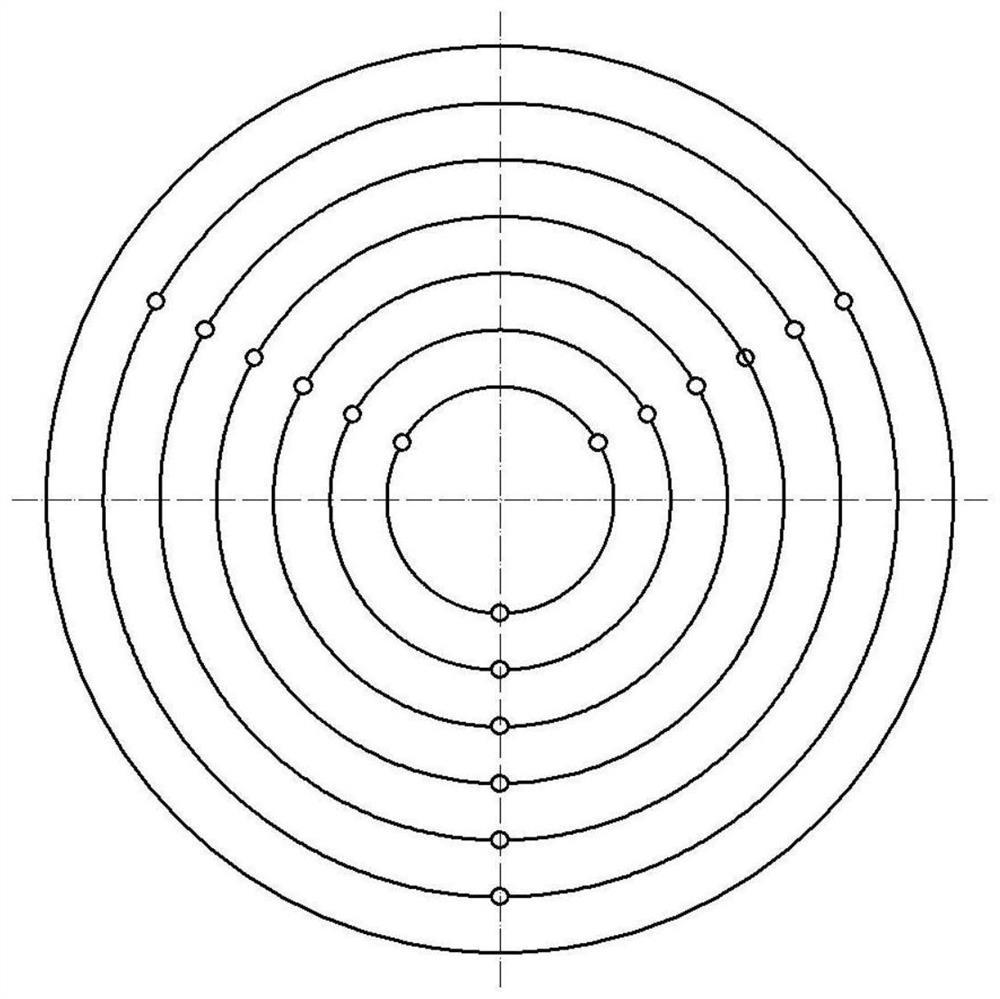

[0030] In this embodiment, a circular line is set on the upper plane of the support body 1; the center of the circular line coincides with the center of the end surface of the head of the screw 2, and the head of the screw 2 is provided with an indicating point for angular displacement.

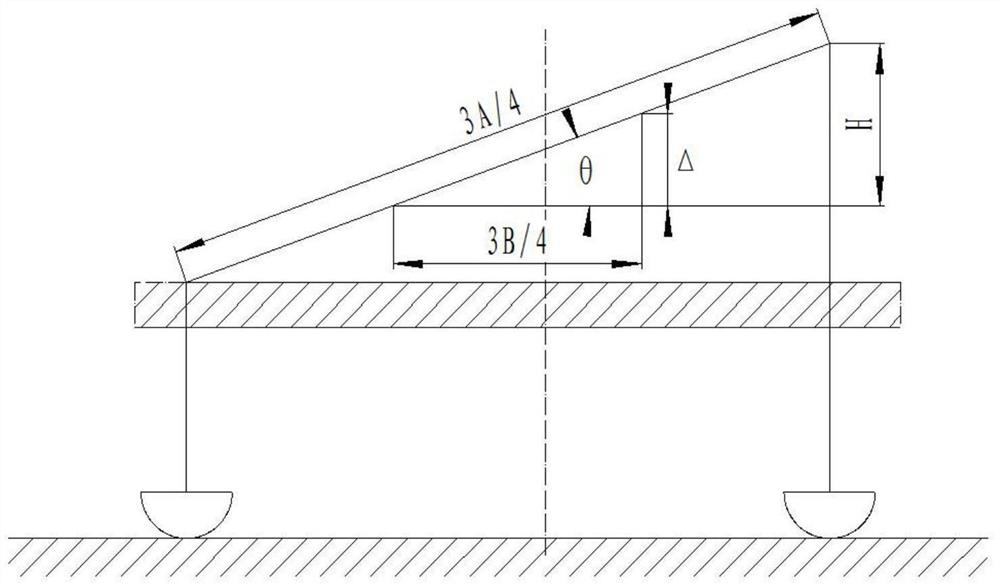

[0031] The leveling device prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com