Battery management module of storage battery, method and device thereof and storage medium

A battery management module and battery management technology, applied in battery circuit devices, circuit devices, measurement devices, etc., can solve the problem of affecting the service life of the battery, increasing the operation and maintenance cost of the smart grid, and affecting the stable operation of the smart terminal. problems, to achieve the effect of improving work efficiency and simplifying management methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

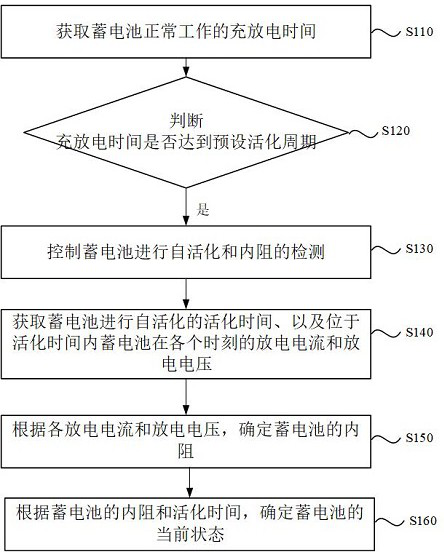

[0052] figure 1 It is a schematic flowchart of a battery management method for a storage battery according to Embodiment 1 of the present invention. The method can be executed by a battery management device for a storage battery, and the device can be composed of hardware and / or software. The battery management method of the storage battery provided by the embodiment of the present invention includes the following steps:

[0053] S110. Obtain the charging and discharging time of the storage battery in normal operation.

[0054]Among them, the battery can convert chemical energy into electrical energy during the discharge process, and the battery can store electrical energy as chemical energy during the charging process. The type of the storage battery may be a lead-acid storage battery or a lithium iron phosphate storage battery. Here, the type of the storage battery is not specifically limited. The storage battery can be a single battery, or it can include one or more batte...

Embodiment 2

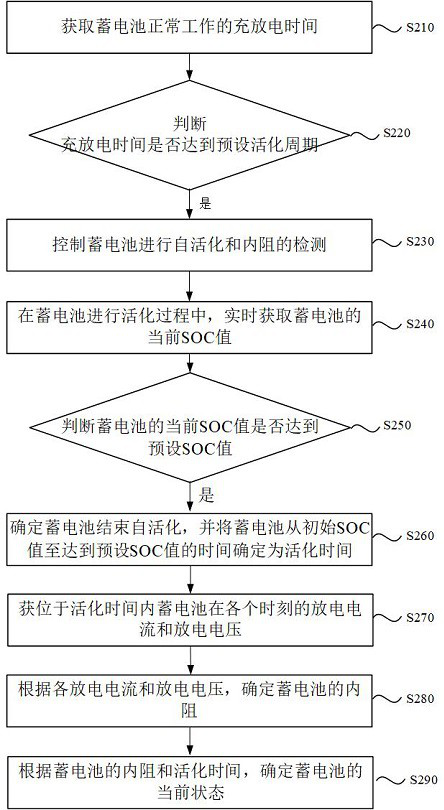

[0071] figure 2 It is a schematic flowchart of a battery management method for a storage battery according to Embodiment 2 of the present invention. On the basis of the above embodiments, a solution for determining the self-activation time of the storage battery is specifically provided. The technical scheme of the present embodiment includes:

[0072] S210. Obtain the charging and discharging time of the storage battery in normal operation.

[0073] S220. Determine whether the charging and discharging time reaches a preset activation period, and if so, execute S230.

[0074] S230. Control the storage battery to perform self-activation and detection of internal resistance.

[0075] S240. Acquiring the current SOC value of the battery in real time during the activation process of the battery.

[0076] S250. Determine whether the current SOC value of the storage battery reaches the preset SOC value, and if so, perform S260.

[0077] S260. Determine that the self-activation ...

Embodiment 3

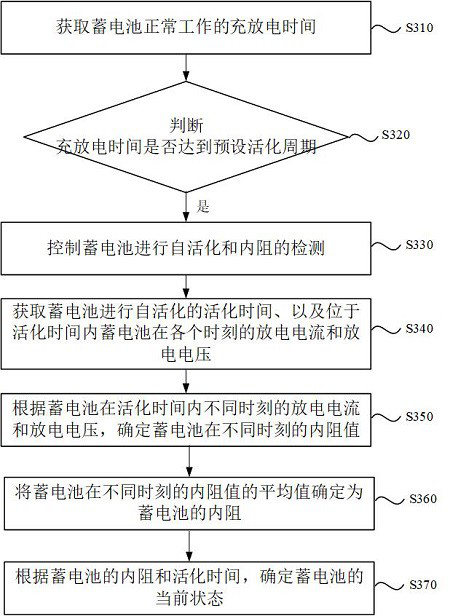

[0085] image 3 It is a schematic flowchart of a battery management method for a storage battery according to Embodiment 3 of the present invention. On the basis of the above embodiments, a solution for determining the self-activation time of the storage battery is specifically provided. The technical scheme of the present embodiment includes:

[0086] S310. Obtain the charging and discharging time of the storage battery in normal operation.

[0087] S320. Determine whether the charging and discharging time reaches the preset activation period, if yes, execute S330.

[0088] S330. Control the storage battery to perform self-activation and detection of internal resistance.

[0089] S340. Acquire the activation time for the battery to self-activate, and the discharge current and discharge voltage of the battery at various moments within the activation time.

[0090] S350. Determine the internal resistance of the battery at different times according to the discharge current and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com