High-speed self-ventilation traction motor

A traction motor and self-ventilation technology, applied in cooling/ventilation devices, asynchronous induction motors, electromechanical devices, etc., can solve problems such as insufficient environmental adaptability, unreasonable motor shaft extension structure, and unsuitable high-speed self-ventilating motors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific embodiments.

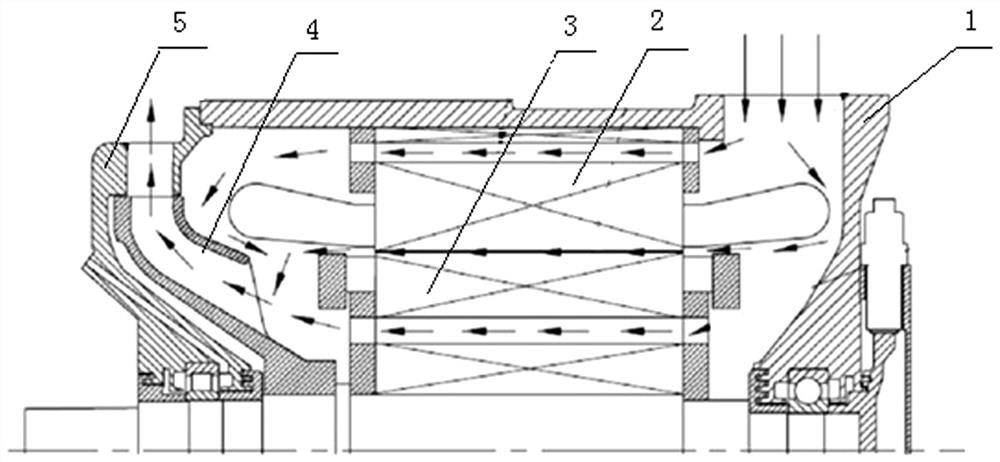

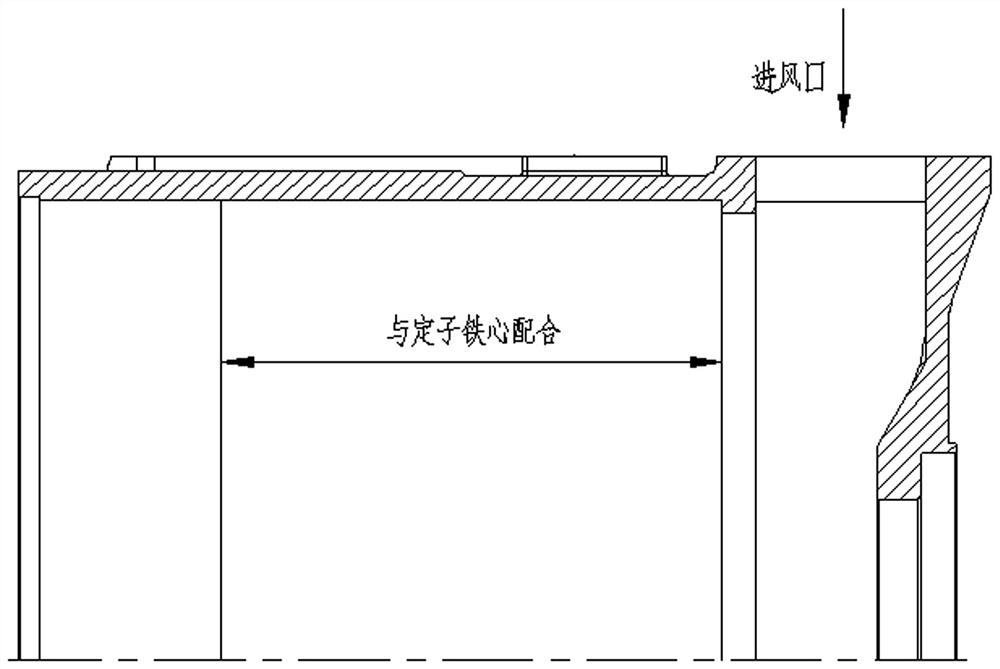

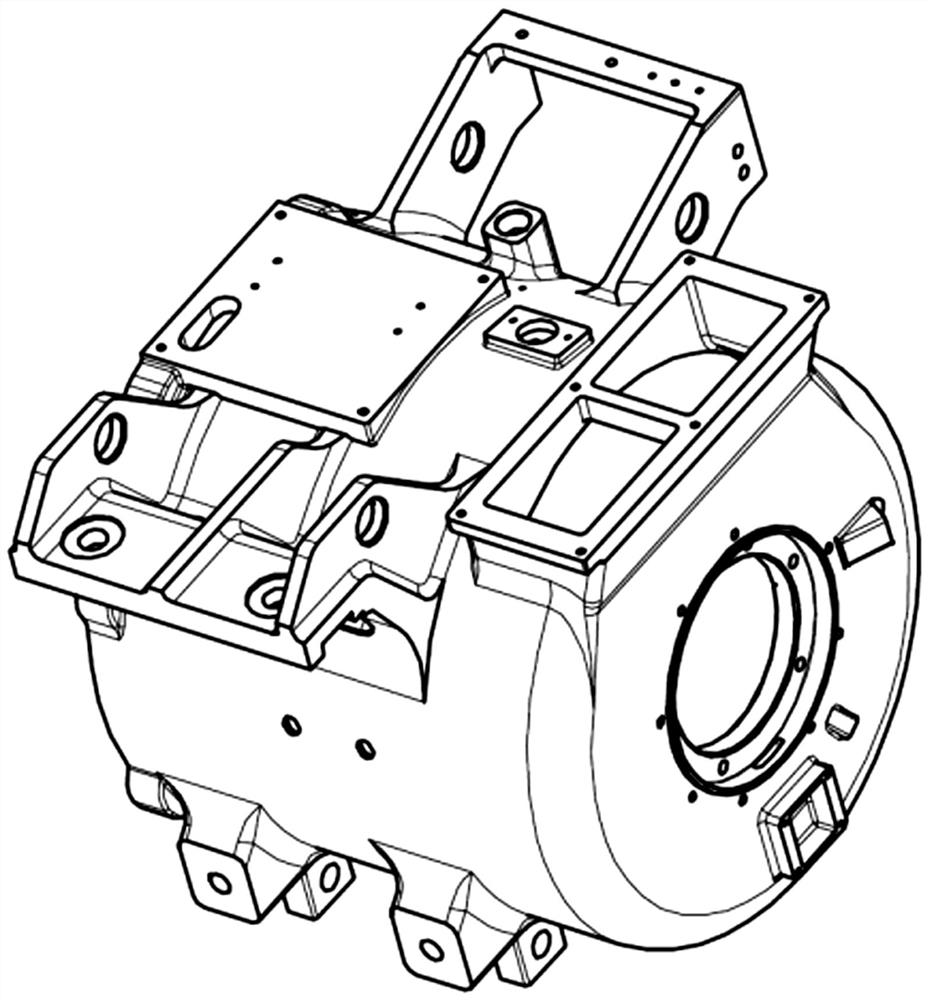

[0040] A high-speed self-ventilated traction motor such as Figure 2~Figure 24Shown: including stator assembly, rotor assembly 3, fan 4 and transmission end cover 5; the stator assembly includes frame 1, stator assembly 2, connecting wire 6, junction box 7 and sealant 8; the stator assembly 2 The heat sleeve is in the base 1, the top of the non-transmission end of the base 1 is provided with an air inlet, the transmission end of the base 1 is open, and the non-transmission end is an open structure; the stator assembly 2 includes a stator Iron core 2.4, coil 2.8, end hoop 2.9 and potting body 2.7, the transmission end of the stator iron core 2.4 is provided with a transmission end stator end plate 2.2 and a transmission end stator pressure plate 2.1, the transmission end stator pressure plate 2.1 is pressed against the transmission end stator Outside the end plate 2.2, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com