Snow making density real-time monitoring method and device of snowmaker and readable storage medium

A real-time monitoring and snowmaking technology, which is applied in ice making, lighting and heating equipment, recreational ice making, etc., can solve the problems of inaccurate calculation of snowmaking volume, inability to monitor in real time, troublesome operation, etc., and achieve simple and convenient testing process, The effect of high test efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

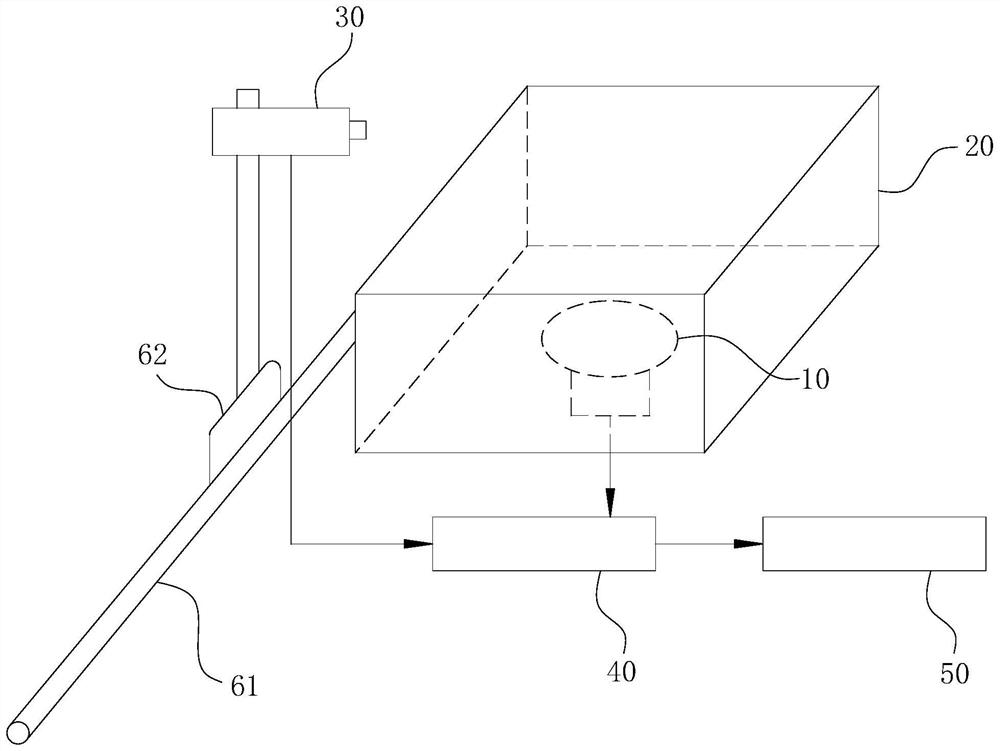

[0026] For ease of understanding, the specific structure and working method of the present invention are further described as follows:

[0027] The specific implementation process of the present invention comprises the following steps:

[0028] Set the moving speed of the transmission assembly, and the frequency of scanning; according to the setting of the transmission assembly, set the time and frequency of collection of the mass sensor; according to the setting of the transmission assembly, determine the start of scanning of the line laser profile scanning sensor 30 start time and scan time.

[0029] start as figure 1 For the device shown, the weight is reset to zero at this time.

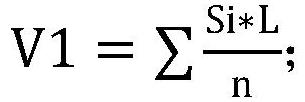

[0030] 1) At time t1, the weight sensor 10 and the data collector 40 work, and start to collect snowmaking information in the sampling channel 20 . At this moment, the transmission assembly runs, and the line laser profile scanning sensor 30 starts to scan, and obtains the data of each point o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com