Automatic detection system for single-layer cutting device

A cutting device and automatic detection technology, applied in the field of cutting bed, can solve the problems that the cutting area cannot be absolutely flat, affect the cutting accuracy and cutting effect, and cannot completely cut, etc., and achieve simple and convenient testing process, less parameters involved, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be described in further detail below based on the accompanying drawings. It should be understood that the specific embodiments described here are only examples, and are not intended to limit the protection scope of the present invention.

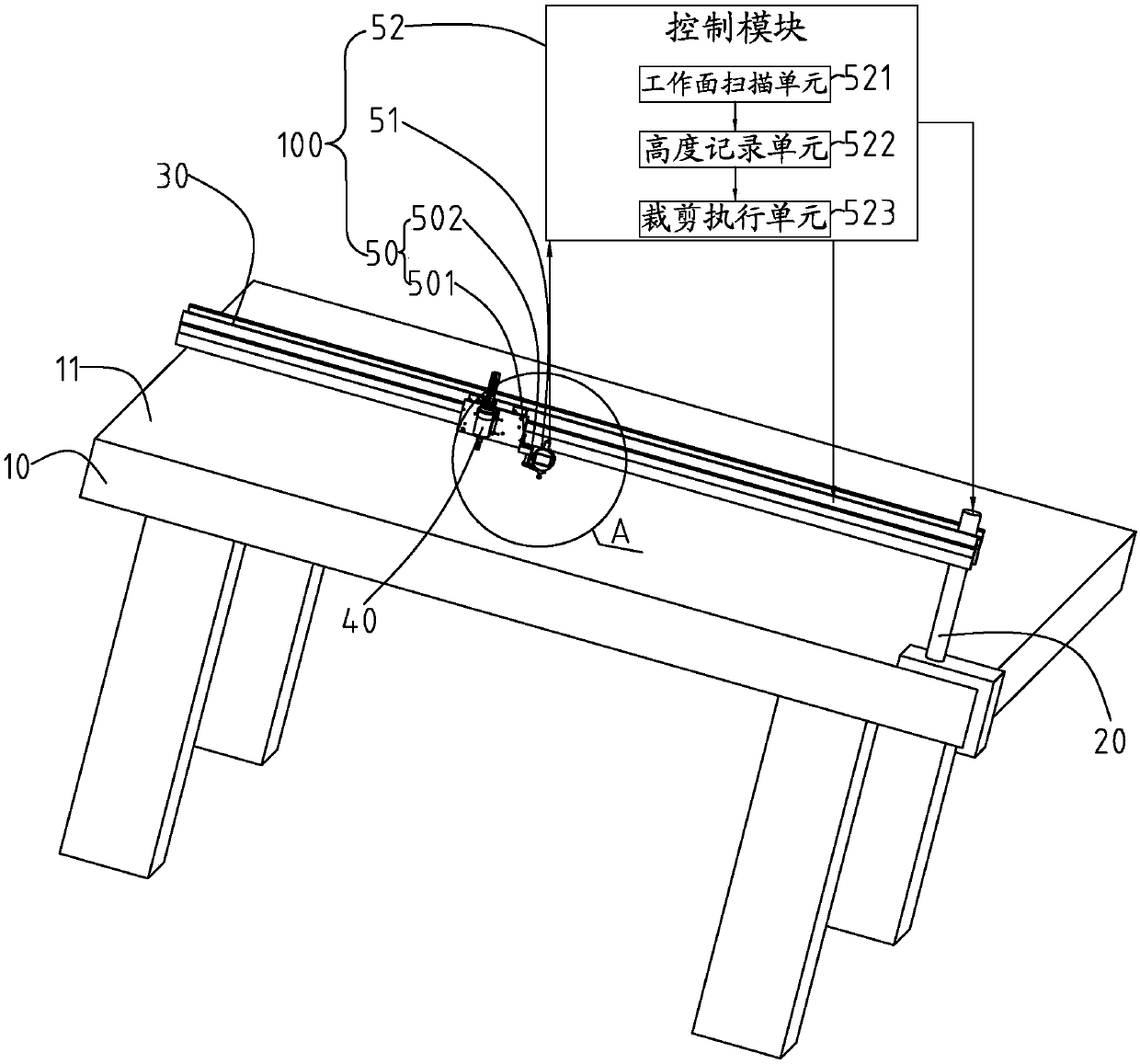

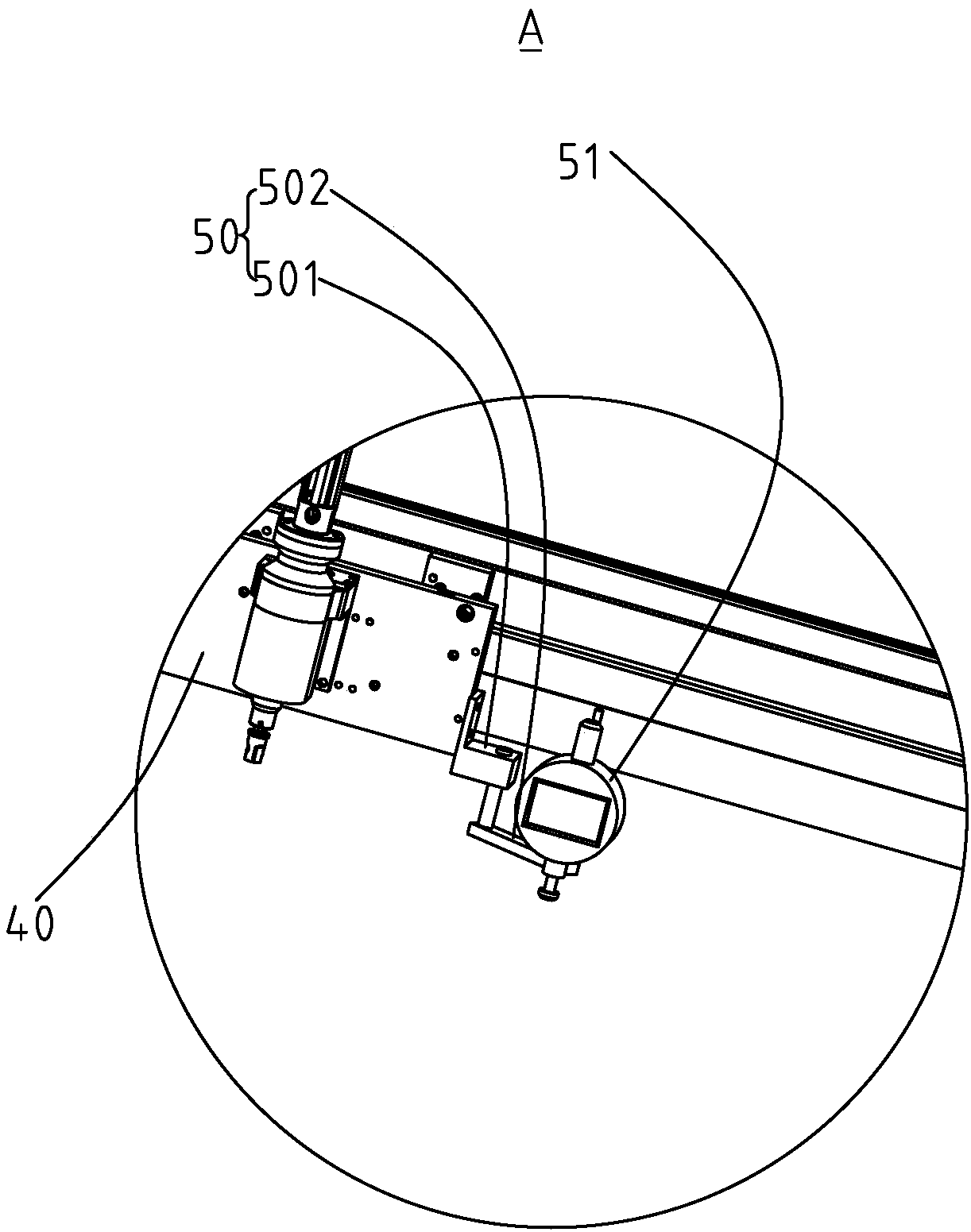

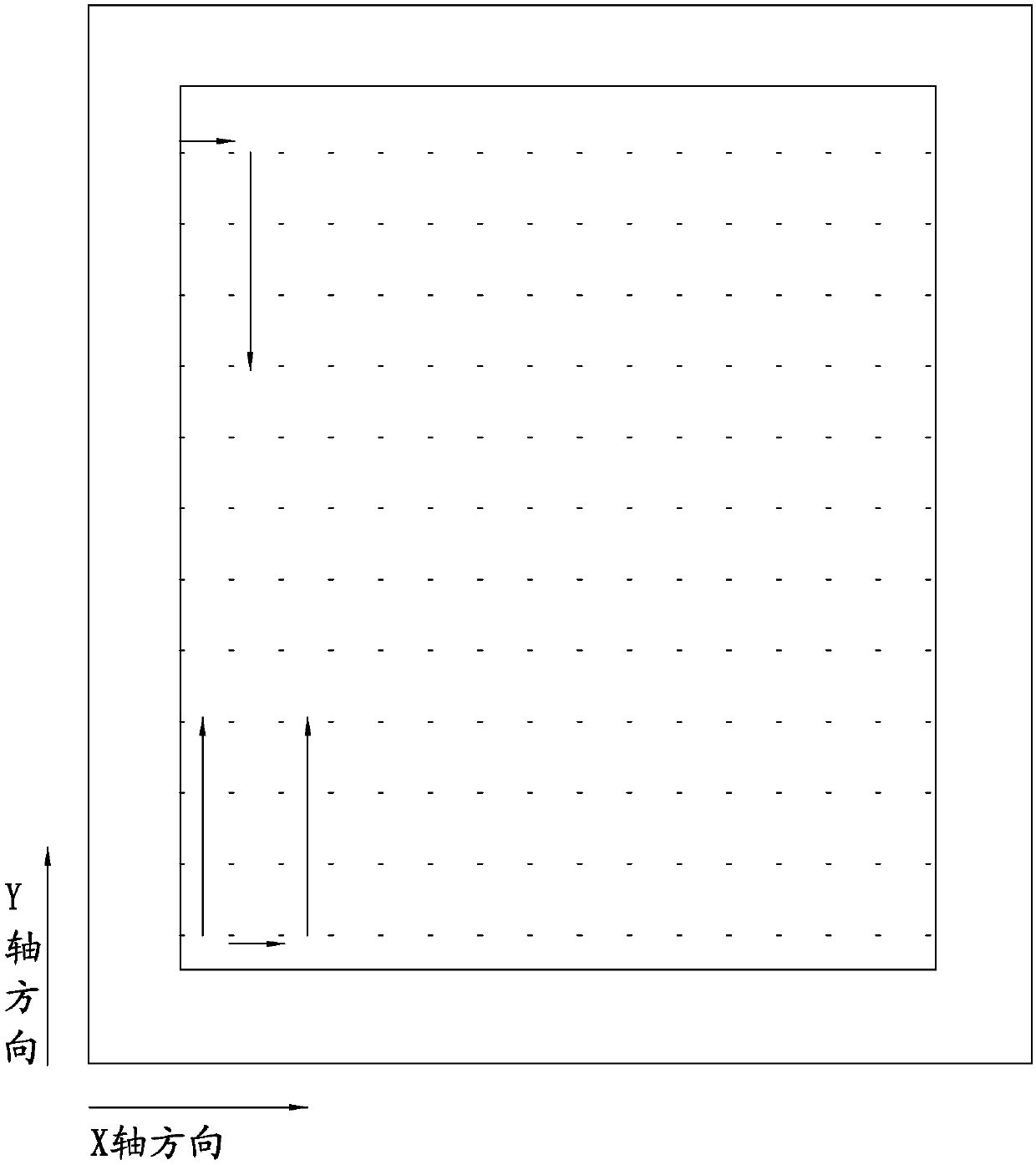

[0020] see figure 1 and figure 2 , which is a structural schematic diagram of an automatic detection system 100 for a single-layer cutting device provided by the present invention. The automatic detection system 100 is especially suitable for single-layer cutting devices. The single-layer cutting device is used for cutting a single-layer fabric, which can be cloth, leather and the like. Since the thickness of the single-layer fabric may be very small, it is especially important to grasp the depth of the lower knife, otherwise it will not be able to completely cut, or the conveyor belt may be damaged. Such as figure 1 The schematic diagram of the structure of the single-layer cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com