Set cement tensile strength testing device and method

A technology of tensile strength and testing equipment, which is applied in the direction of measuring equipment, strength characteristics, and preparation of test samples. It can solve problems such as difficult placement, eccentric compression of samples, easy eccentricity of stretching, etc., and achieves a convenient and simple testing process. , Improve the efficiency of use, and the effect of simple sample preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

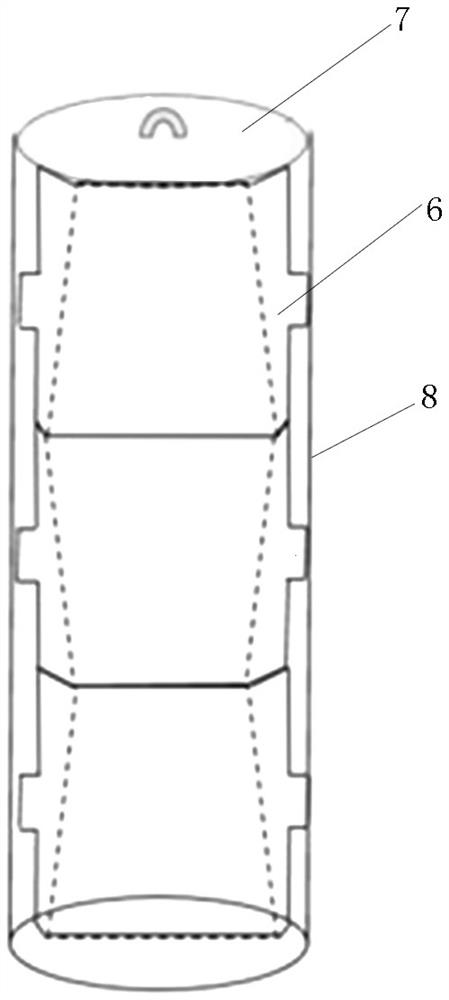

[0044] Such as Figure 4 As shown, a cement stone tensile strength test device includes a tensile support 9 and a mold assembly 6 fixed by the tensile device and subjected to a tensile test. Wherein the mold assembly 6 is formed by overlapping and combining a plurality of molds 1. The mold assembly 6 has molded cement stones. The cement stones are formed by cement slurry in multiple overlapping molds 1. After the cement slurry is formed into cement stones , and multiple overlapping molds 1 are connected as a whole through cement stones.

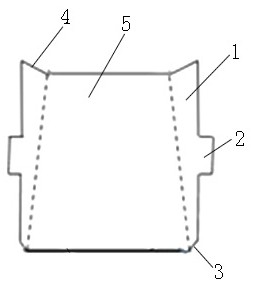

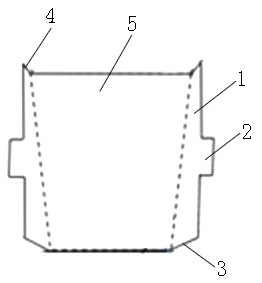

[0045] Such as figure 1 and figure 2 shown, where Die 1 is the size The round mold, that is, the mold 1 body is cylindrical, in order to enable the fixed clamp 18 and the force sleeve 15 on the tensile support 9 to quickly and convenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com