Portable optical three-dimensional scanning equipment calibration device and use method thereof

A technology for three-dimensional scanning and calibration devices, which is applied in the field of optical three-dimensional scanning, can solve the problems of poor device stability, unfavorable calibration work, high cost, etc., and achieve the effects of simple and portable device structure, convenient on-site detection, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

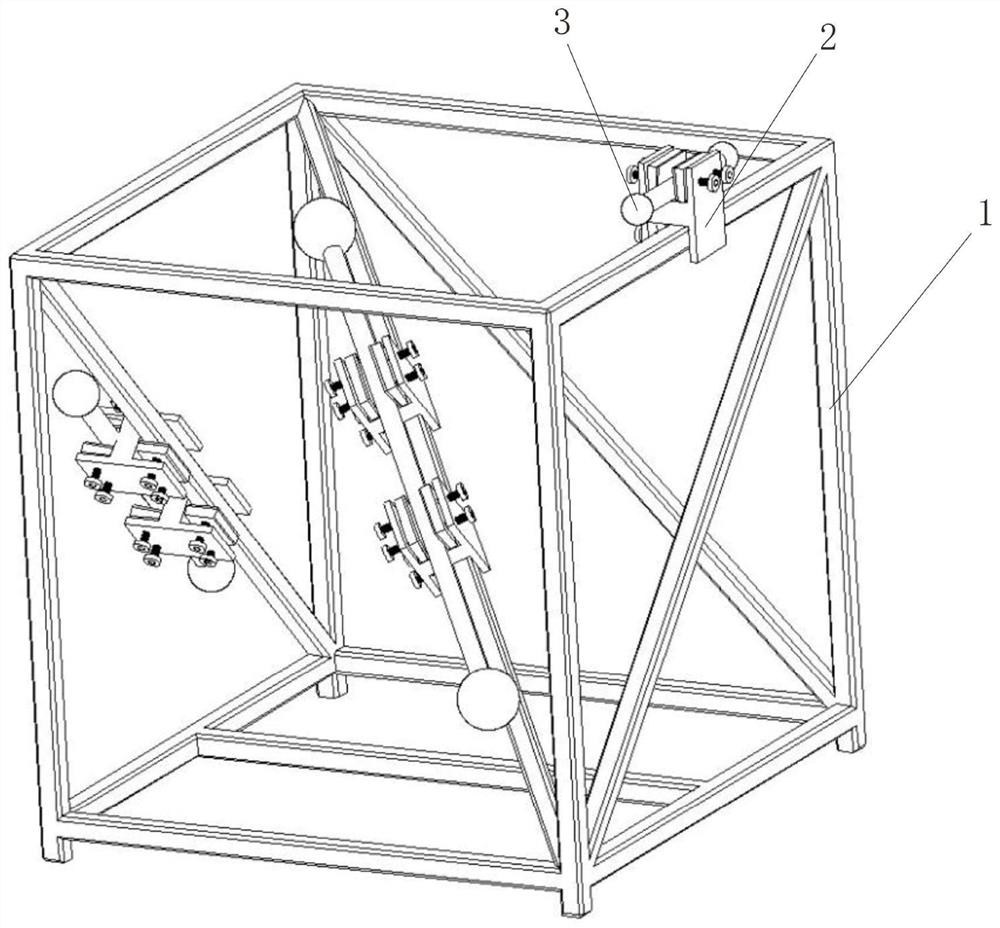

[0029] refer to figure 1 , a portable optical three-dimensional scanning equipment calibration device, including an integrated metal frame 1, a clamping frame 2, and a calibration bat 3; the integrated metal frame 1 is a frame formed by splicing metal materials, and the integrated metal frame 1 includes 12 right angles Edges, 3 facing diagonal edges, and 1 body diagonal edge to provide different calibration orientations for optical 3D scanning equipment. One end of the clamping frame 2 is disassembled and connected with the integrated metal frame 1 , and the other end of the clamping frame 2 clamps the calibration bat 3 . The calibration bat 3 is a two-ball or multi-ball bat, and the calibration balls of the calibration bat 3 are made of matte ceramics or matte stainless steel with diffuse reflection surface characteristics.

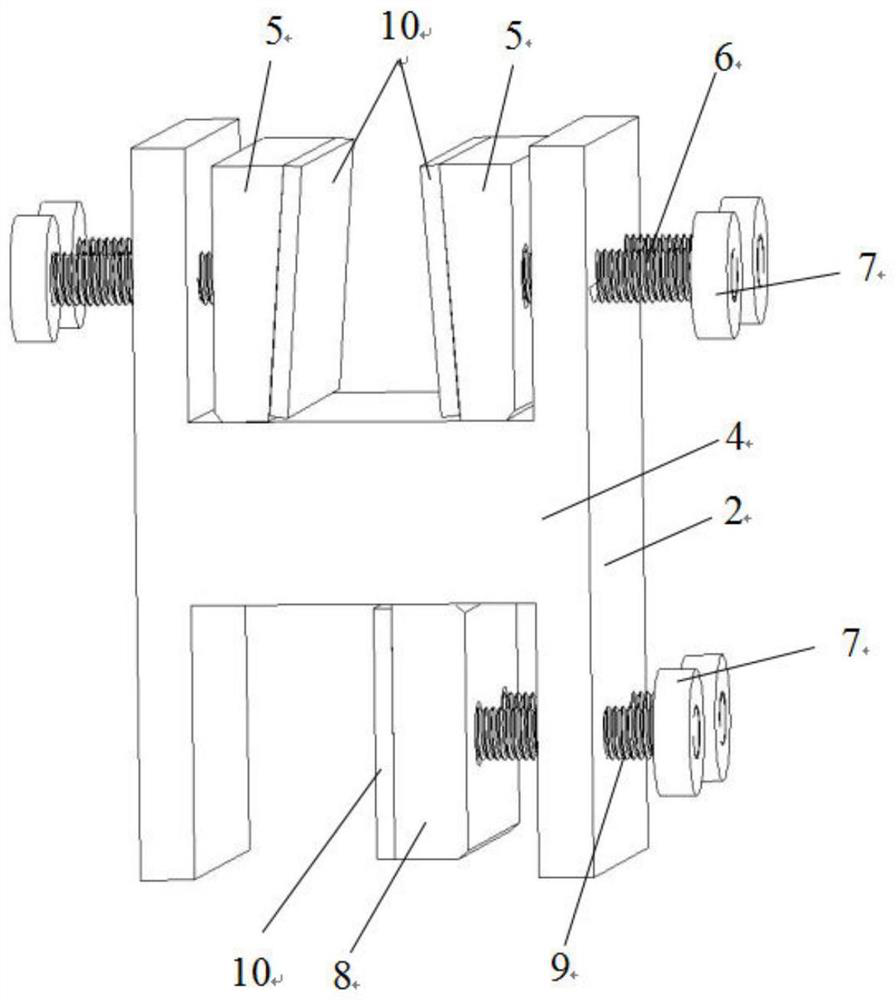

[0030] refer to figure 2 , the clamping frame 2 includes an H-shaped frame body 4, the upper end of the H-shaped frame body 4 is provided with a firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com