Two-dimensional bar code design method for steel number identification

A two-dimensional barcode and design method technology, which is applied to the recording carrier used by the machine, calculation, computer parts, etc., can solve the problems of inability to realize clear automatic spraying, mottled handwriting and falling off, limited spraying equipment capacity, etc., to achieve convenient automatic Spraying and manual drawing, improve the recognition rate, and realize the effect of automatic recognition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

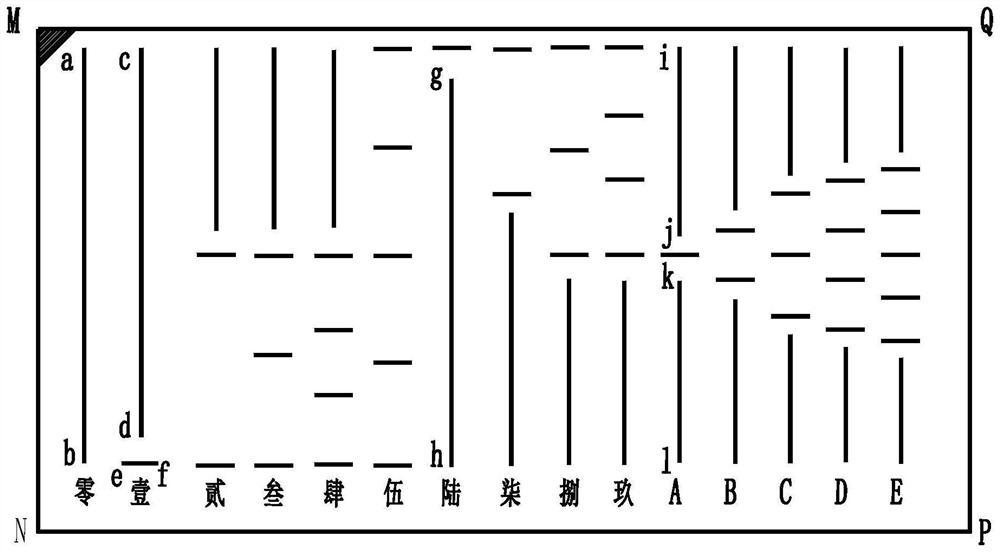

[0030] refer to figure 1 , is the first embodiment of the present invention, and this embodiment provides a kind of two-dimensional bar code design method that is used for steel serial number identification, comprises:

[0031] S1: Use the outer rectangular frame MNPQ as the boundary of the two-dimensional barcode, and design a triangular block at point M in the upper left corner of the outer rectangular frame MNPQ;

[0032] Preferably, as a reference point for the image recognition algorithm, in this embodiment, a triangular block is designed at the M point in the upper left corner of the outer rectangular frame MNPQ, so as to facilitate the overall positioning of the two-dimensional barcode during the image recognition process.

[0033] Wherein, the M terminal is defined as the upper end, and the N terminal is defined as the lower end.

[0034] S2: Based on the actual production situation on site, numbers and English characters are used as characterizing characters in the t...

Embodiment 2

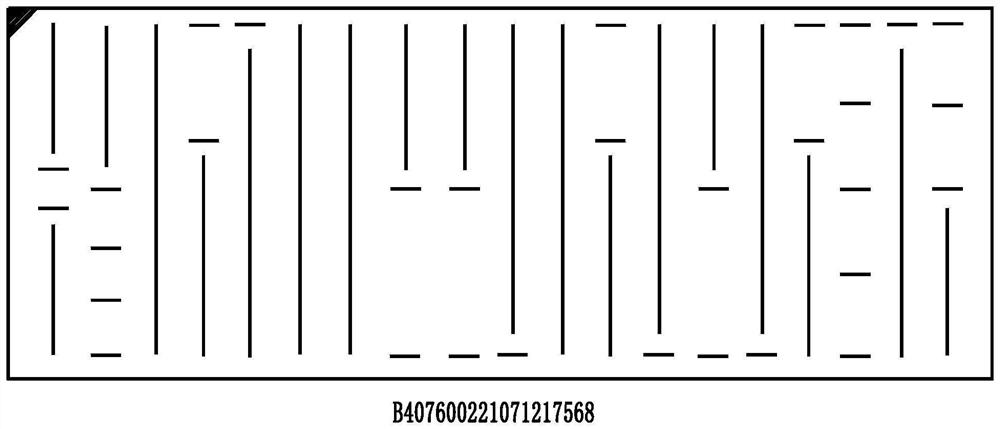

[0062] In order to verify and explain the technical effect adopted in this method, this embodiment chooses the traditional technical scheme and adopts this method to conduct a comparative test, and compares the test results by means of scientific demonstration to verify the real effect of this method.

[0063] In order to verify that the two-dimensional barcode designed by this method has a higher recognition rate than the traditional technical solution, in this embodiment, the traditional technical solution and this method will be used to design the steel serial number identification (two-dimensional barcode) respectively, and through the machine identification algorithm Identify and compare.

[0064] According to the requirements of the process, the steel product number has a fixed information format (for example: B40760022107121756 indicates the steel product of the No. The accumulative sum of the values corresponding to the characters is 62. This method is to realize tha...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap