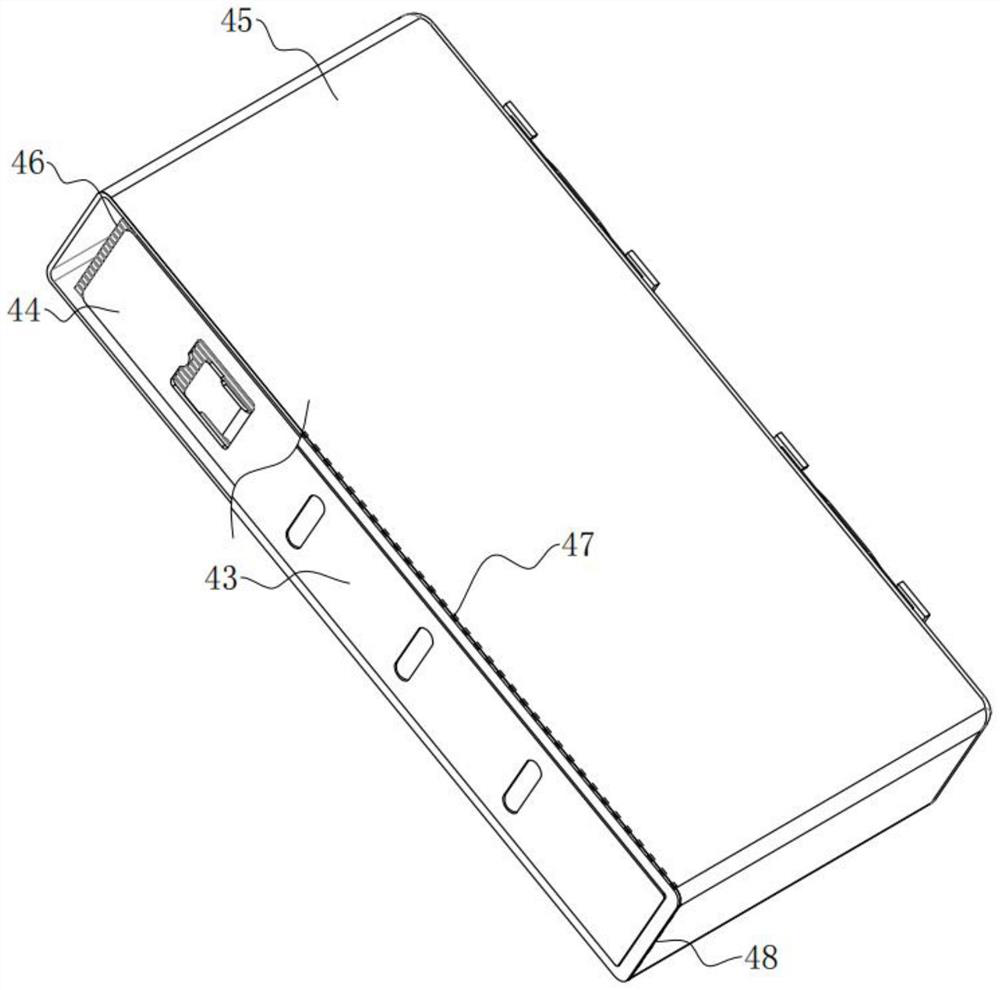

Automatic positioning device for battery pack cover plate welding

A cover plate welding and automatic positioning technology, used in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of low battery pack picking and placing efficiency, offset of pressing battery packs, etc., achieving a high degree of automation and positioning pressure. The effect of high tightening efficiency and improved pick-and-place efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

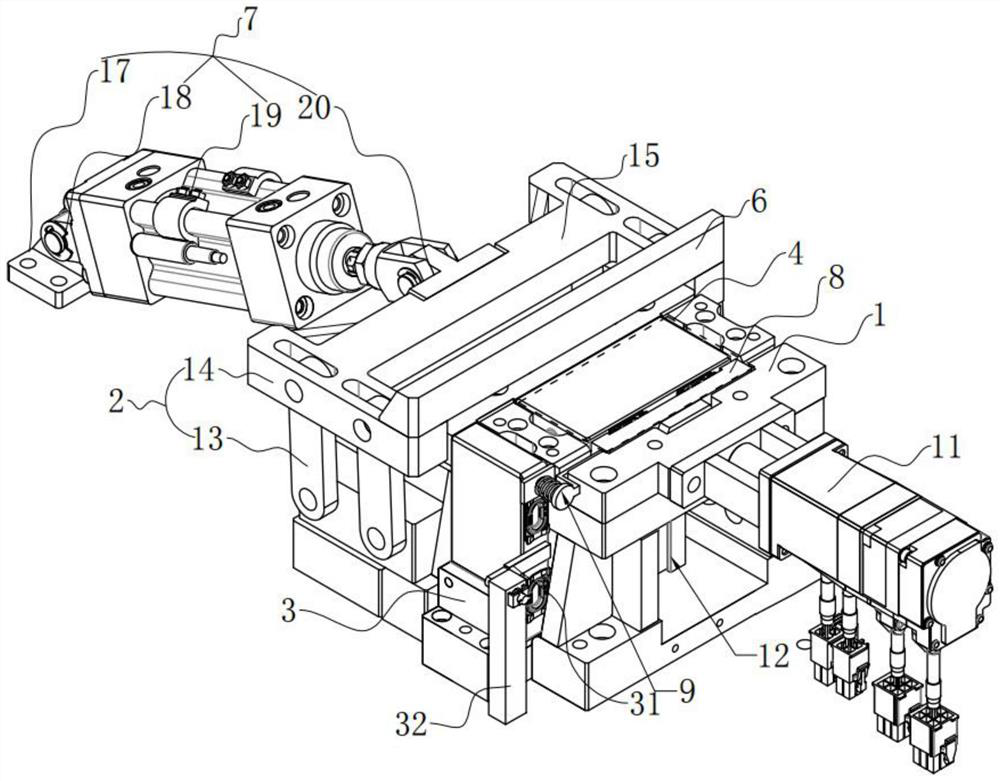

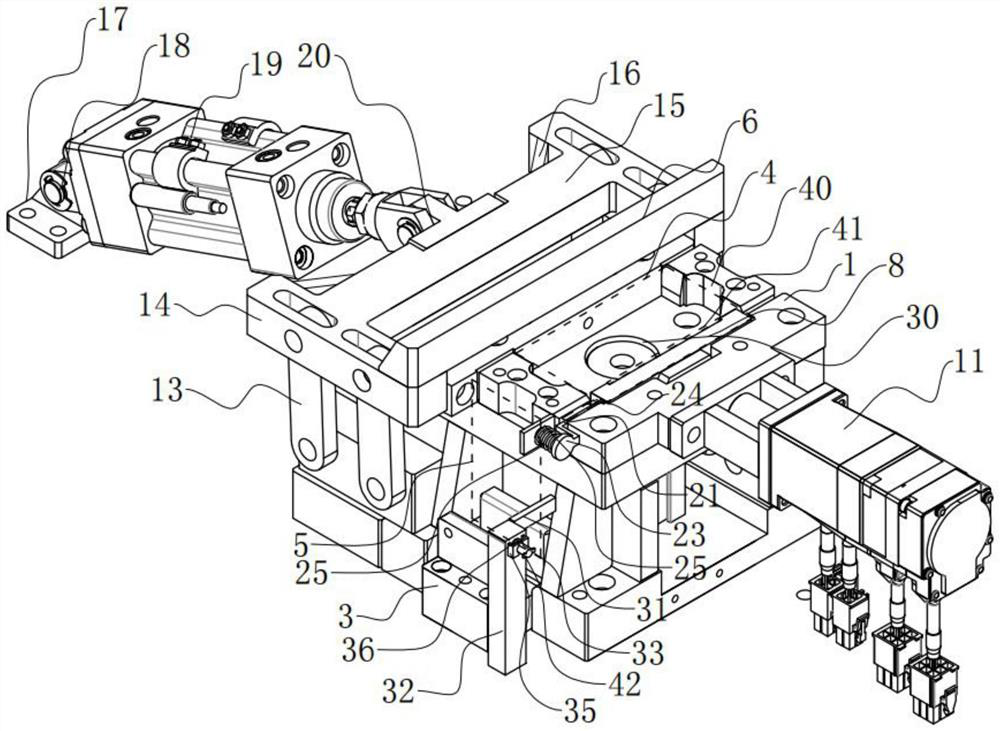

[0023] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings. It should be noted that the words "upper" and "lower" used in the following description refer to the attached figure 2 In the directions, the words "bottom" and "top" refer to directions toward the geometric center of a particular part.

[0024] The most critical idea of the present invention is: through the positioning seat 1, the positioning groove 4, the positioning block 3 and the limit through groove 5, the preliminary positioning of the horizontally placed battery pack and the vertically placed battery pack is realized; through the rotating motor 11, the screw rod 10. The pressing part 9 and the side pressing plate 8 automatically compress the two extremes of the horizontally placed battery pack and the vertically placed battery pack; realize the automati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com