Wear-resistant nylon top sliding plate structure for mining machine

A nylon and skateboard technology, applied in the direction of slitting machinery, earth-moving drilling and mining, etc., can solve the problems of low work efficiency and high labor intensity of staff, and achieve the effect of convenient operation, simple structure and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

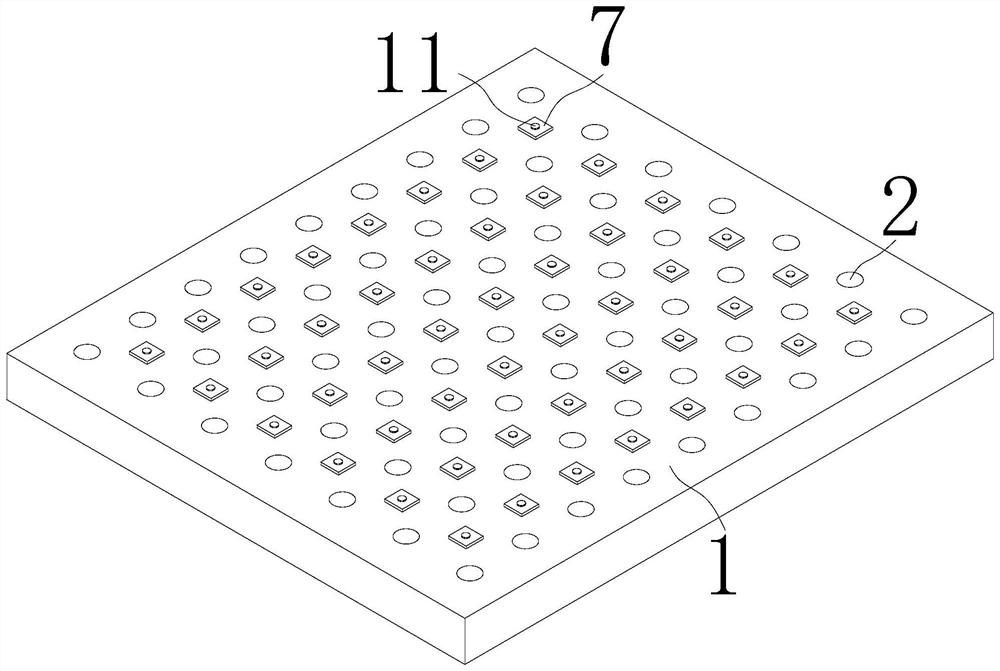

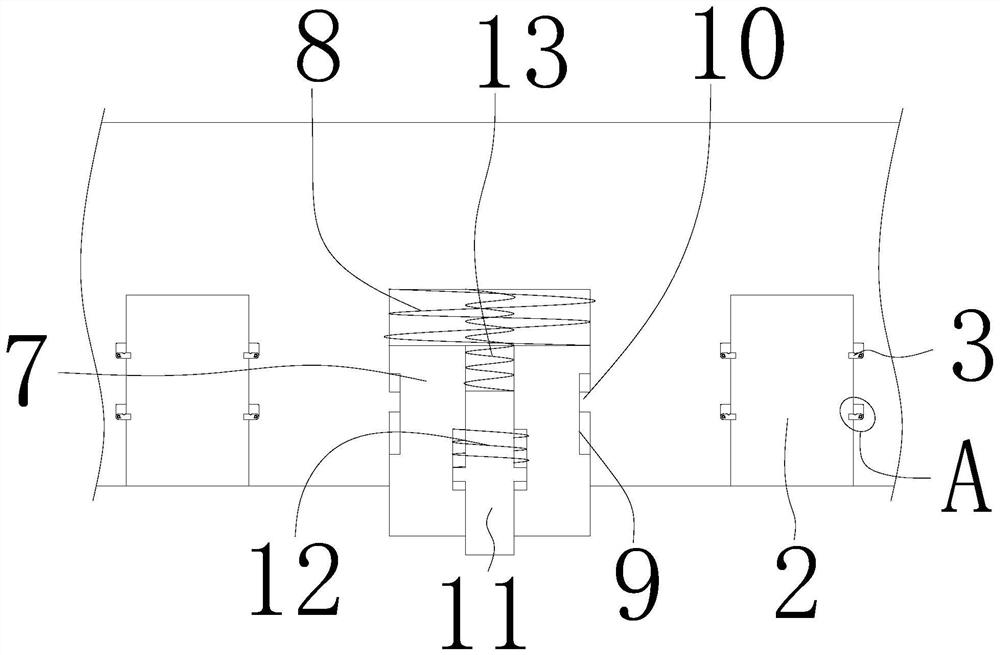

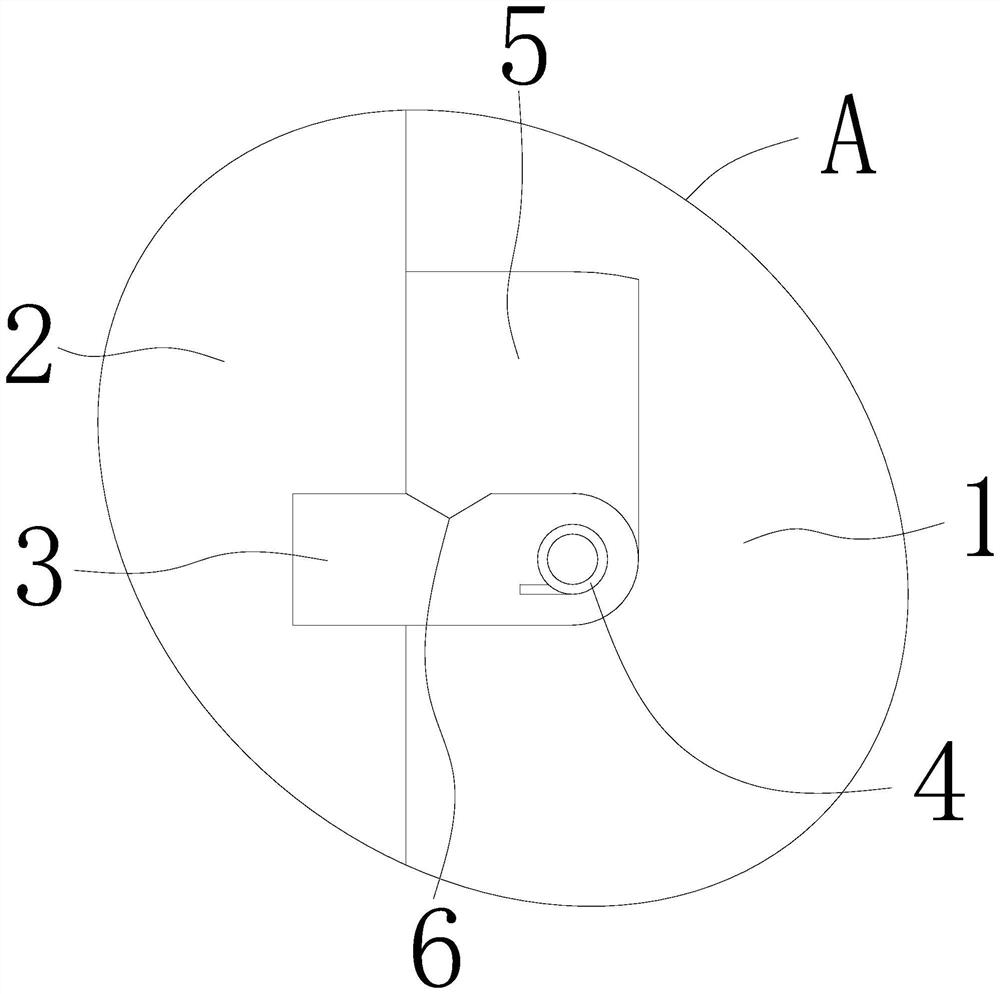

[0020] refer to Figure 1-6 , the present invention proposes a wear-resistant nylon top slide plate structure for a mining machine, including a nylon slide plate 1 and a threaded rod, wherein:

[0021] One side of the nylon skateboard 1 is provided with a plurality of installation holes 2, the threaded rod is detachably inserted into the installation hole 2 and the threaded rod and the installation hole 2 are a transitional fit, and the installation hole 2 is equipped with a one-way locking anti-off mechanism;

[0022] When people install the nylon skateboard 1, people can place the nylon skateboard 1 on the top of the mining machine, so that the threaded columns on the mining machine are inserted into the installation holes 2 one by one, and when people hammer the nylon skateboard 1 with a hammer, because the installation The hole 2 and the threaded rod are transition fit or clearance fit. When hammering, the threaded rod can be inserted into the installation hole 2 quickly, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com